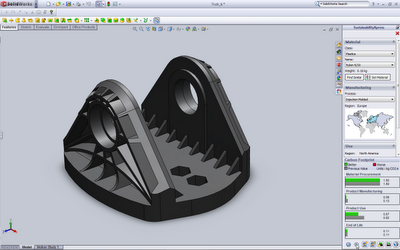

SustainabillityXpress loads up into the Browser panel to the right-hand side of the UI.

This release onto SolidWorks’ Labs web-site is something I’ve been looking forward to since the team behind gave a sneak peak at SolidWorks World back in January. What it represents is a partnership between SolidWorks and an organisation called Thinkstep, an expert in sustainability and materials science. The end result is looking to be a set of tools, starting with part-only Xpress variant, then a fuller fledged assembly analysis tools coming on stream and presumably into the Office Premium bundle. and sold as a seperate product.

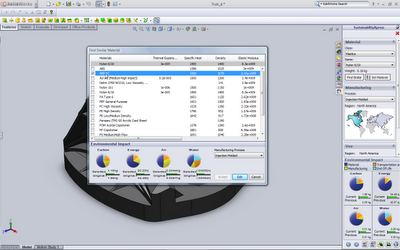

What the tools do is interrogate your part’s form, it’s size then requests additional information such as material (if you haven’t got it set in the part file), the manufacturing process. The system filters based on your material selection – for example, selecting a plastic, you get Injection moulded and Extruded as options. It then asks for geographic information, asking for details on where your part is manufactured and where it’s in use. Rather oddly, the system currently only has three geographic “regions” – Europe, North America, Asia and Japan.

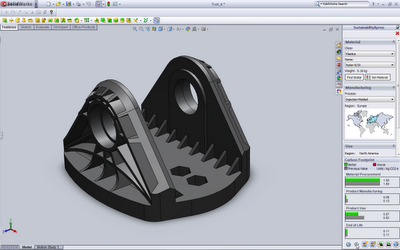

This is then used to hook into Thinkstep’s huge database (available in a system called Gabi) of materials lifecycle information and gives you all manner of results for environment issues. There are four or five panels that give you information about the environmental impact of sourcing the material, processing it, shipping it and it being in use and of course, in these Cradle to Grave times, it’s end of life disposal. The key metrics the systems gives you relate to Carbon footprint, Energy Consumed (over the complete lifecycle of the product), Air Acidification (which covers the emissions such as sulfur dioxide and nitrous oxides) and Water Eutrophication (pretty much the contamination of water and resultant damage to the surrounding ecology).

The four panels that show the key environmental factors and comparison between the original and new material selection.

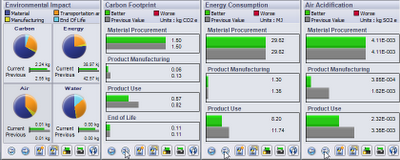

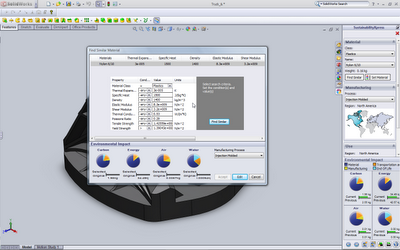

The system has a set of baseline tools, that allow you to select your starting material, perhaps your initial guess or the material used in a previous generation of a part, zero out the values, then use the tools within the system to find alternatives and very quickly and very graphically see how the various values improve or degrade. The thing that interests me is the Find Similar tool that’s used to find those alternatives. As a massive advocate of materials science and the use of materials selection techniques in design and engineering, this tool holds some promise. In basics, it presents you with a set of selection criteria in which to search the underlying database to find alternative that have the same material characteristics.

A basic set of materials search options are available to find alternative materials.

All the usual things are there including material class (alloys, plastics etc etc), density, thermal expansion, yield strength, elastic and shear moduli, tensile and yield strengths, Poissons ratio. You can then set limits to those values such Greater than, Less than, Approximate (rather disappointingly there’s no range-based search) and search the database to find materials than match your criteria.

A list of alternatives that match your search criteria are presented and can be evaluated against your current material selection.

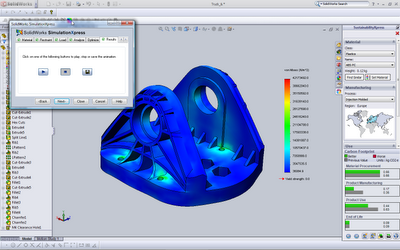

The tool then presents you with a list of alternative materials which you can then gauge the difference in relation to those environmental factors graphically and make a decision upon. What’s interesting of course, is that while you’re unlikely to make a material selection based on environmental factors alone, you can do so with an informed idea of how ‘green’ those alternatives are, then explore further. Using simulation to test the performance of new potential material.

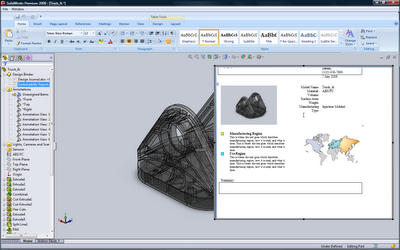

The process you’ve been through can be documented and distributed using an automatically generated report (created from within the panel) that outputs to Word and gives you the basic starting point for a report proper. The report is also saved in the Design Binder and as such is associated with the part file. Personally, I think using Word to generate these things is a bad idea (preferring a HTML or PDF document) – particularly as I didn’t have Office install on my workstation.

The report is stored within the Design Binder folder within the SolidWorks part file – or can be output as a Word Doc.

What I like about this, even though it’s at a very early stage is a two fold thing. Firstly, there’s the simple fact that these issues, addressed by the tool, are going to become more and more of an issue in the coming years, as materials become more scarce, as governmental and international legislation cracks down as resources dry out and the simple fact that as designers, we have a moral obligation that the products we produce minimize the harm to the environment. By giving SolidWorks users the tools to quickly evaluate these factors, at an early stage, nothing but good can come of it.

But that’s assuming that the tool is actually used. This is perhaps the biggest challenge that this and the other tools from other vendors, face. Getting the designers and engineers to use them to their potential. Particularly in the US, I’ve often heard the idea bandied around that these things, this inevitable movement towards scarcity of materials and resources is a myth. Something which baffles me every time I hear it. It’s common sense. The planet is not a renewing resource, it’s a finite closed system and if we continue down this path, things are going to start running out. We’re used more than the planet or we can generate. continue doing that and it’ll run out. That’s common sense.

Even if this is not a common thought, you also have the simple fact that environmental factors, when discussed in the context of everyday design and engineering, are not on people’s priority lists when facing economic disaster, the drive for lower cost, higher quality more innovative products. Quite simply, are people going to have time to care about environmental factors when their job in on the line?

Perhaps behind the headline ’sustainability’ focussed nature of this tool, there lies something that everyone can gain benefit from. By giving you search and filtering tools, you can find alternative materials, alternative methods of manufacture that can make your design work more effective, save cost, save weight, add strength with less material. That’s something I think is incredibly powerful. and while it doesn’t have the richness of a material selection tool such as CES Selector 2008 (from Granta Design), it is a start.

For many years, I’ve been wondering when one of the CAD vendors would make the logical connection between material selection and 3D-based design – there’s huge syngergy (and I mean that in the truest sense of the word) there to be had. It just takes a vendor to make the leap. Perhaps this is the first of many. I do hope so.