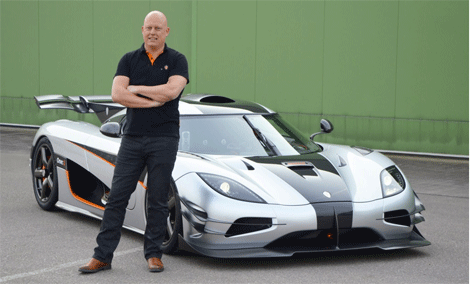

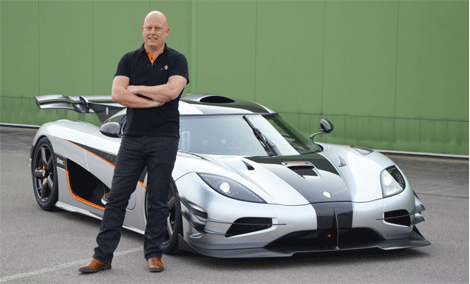

You can either try and make sense of the headline here, or you can watch crazy ol’ Christian von Koenigsegg explain how his insane automotive company takes advantage of 3D Printing technology.

Your choice.

//www.youtube.com/embed/Dw6cs7opvzA?rel=0

In the video Christian talks about how they’re using 3D scanning and 3D printing to create parts for its craaaaazy fast One:1 hyper car, including the usual array of physical prototypes, testing aero units, and one of the world’s largest 3D sintered titanium parts – the exhaust – saving a massive 1kg of weight over a standard CNC-machined aluminium piece.

With low volume production Koenigsegg are benefitting more than most of their competitors from 3D printing production parts – meaning lighter cars and even more speed.

What’s best about this video is that Christian knows the ins and outs of all the technology used by the design and manufacturing team. There’s not many automotive CEOs that could get their hands dirty on the shop floor, let alone extol the values of the different parts of the design process.