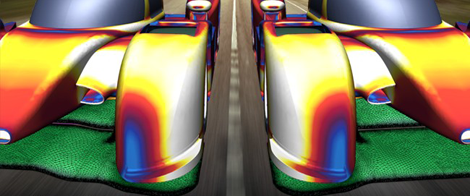

The latest release of STAR-CCM+ looks to help designers understand simulation results better

With additions such as new interactive data visualization in CD-Adapco’s STAR-CCM+ v11.02, the latest release is looking to provide further critical insight to improve product design.

The simulation solution, recently acquired by Siemens PLM, announced its new modeling capabilities and brings productivity and usability enhancements that give designers “necessary tools to elevate their confidence in the simulation results”.

The introduction of Data Focus, a visualisation aid to explore and interrogate simulation results interactively, provides a live and interactive link between quantitative numerical data in plots and qualitative visual data in scenes.

“We are offering our customers an exclusive feature to explore their analysis results in an entirely new way,” said Jean-Claude Ercolanelli, CD-adapco senior VP of Product Management.

“Data Focus directly addresses the challenges engineers face when trying to understand large sets of interdependent data and complex 3D vector fields. Users will deepen the interpretation of their simulation results, and will have a stronger insight which is needed to discover better designs.”

STAR-CCM+ v11.02 includes 40 new features drawn from ideas submitted through IdeaStorm customer forum, and includes:

– Local Surface Remeshing: allows for remeshing only selected areas when changing mesh parameters or performing design changes, reducing surface mesh generation time up to an order of magnitude

– Native Cylindrical Primitive Particle Types in DEM: reduces turnaround time and improves accuracy by representing particles, such as tablets or pellets, using true cylinders as opposed to a collection of spheres

– Co-extrusion in Computational Rheology: expands the application scope of STAR-CCM+ to include complex extrusion processes involving multiple material streams

– Hinged Multi-Body Motion: allows for accurate modeling of complex dynamic fluid body interaction scenarios where multiple parts are coupled together with common mechanical joints

– Fluid-Structure Interactions of Rotating Bodies: enables efficient two-way FSI coupling by simulating rotating solid parts in a local rotating frame of reference, leading to significant time savings in throughput, specifically for applications in the Marine Industry

This release also provides an update to Estimating Hull Performance (EHP) and welcomes a new member to the family of Virtual Product Development (VPD) tools with the introduction of CFD-based mixing simulation tool Admixtus.

By using Admixtus together with STAR-CCM+, engineers in the chemical and processing industries should be able to experience significant productivity gains through workflow automation and have the freedom to explore many designs early in the product development cycle.