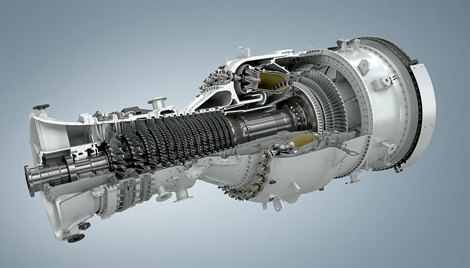

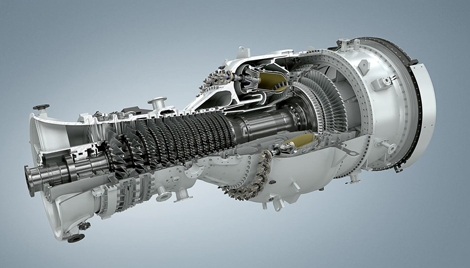

3D printing with metals might be the best way for Siemens to maintain and manufacture its gas turbines

Siemens has opened a production facility for metal 3D printed components in Finspång, Sweden at a cost of around 200 million Swedish Krona (€21.4 million), and is the first step in the company’s plans for the mass manufacture and repair of metal parts with additive manufacturing.

A long-term investment, the site is focussed on building up the skills and experience to lead to new ideas and developments in the field, while working predominantly with EOS Direct Metal Laser Sintering machines.

The workshop will employ 20 operators and engineers and will be used to develop new and improved components for the Siemens’ series of industrial gas turbines, for the power industry.

Gas turbines are technically challenging to produce, and it is hoped that 3D printing holds the key to significantly faster repair times, from months to weeks.