The roll hemming process simulated in AutoFormplus R6

AutoForm Engineering, a leading supplier of software solutions for the sheet metal forming industry, has released AutoForm-HemPlannerplus, supporting roll, conventional die and table top hemming.

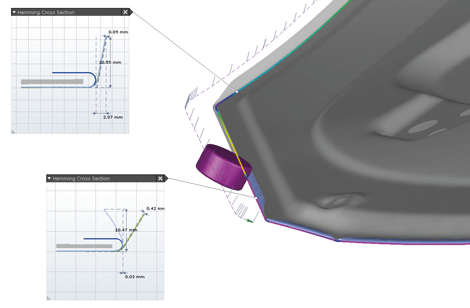

Used in the automotive industry to join two sheet metal panels together, where the flange of the outer panel is bent over the inner one, hemming is commonly used to assemble the outer parts of a car, such as doors, bonnet, boot and fenders, accuracy is very important for surface quality.

The software is fully integrated into AutoFormplus’ R6 version, adding efficiency to the workflow and a newly enhanced graphical user interface.

Simulation showing the evaluation of hemming defects and the material roll-in

“In combination with our powerful solver algorithms, AutoForm-HemPlannerplus ensures the efficient planning of hemming processes,” said Dr. Markus Thomma, AutoForm Engineering corporate marketing director.

“Users will benefit greatly from a fully integrated hemming solution provided by AutoFormplus R6. The new level of speed which can be achieved is a particular highlight of the software. Depending on the selected hemming process and geometry, a hood can now be simulated in just two to six hours, which represents a significant additional benefit for users working in this field.”

Thomma claims the tool allows for efficient planning of hemming processes to meet quality and cost requirements, effective implementation for early feasibility and final validation studies, rapid identification of typical hemming defects, prediction of full assembly springback after hemming as well as data exchange internally between different departments and externally between OEMs and suppliers.

In addition, the software allows for compensation of inner and outer parts as well as any adjustments of the hemming equipment.