Green laser technology could be the answer for all those 3D laser scanning issues involving reflective surfaces

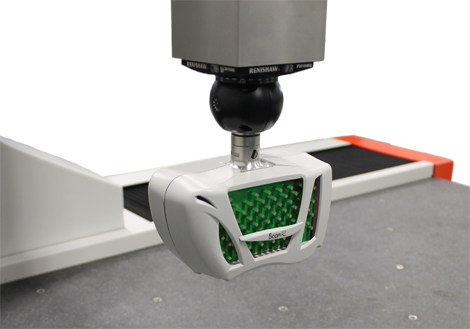

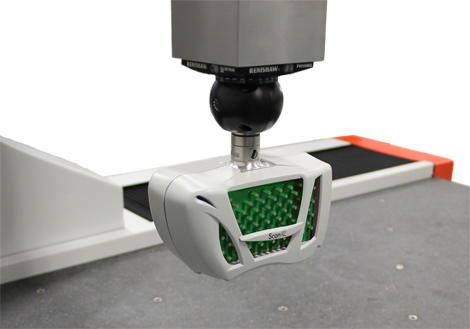

Perceptron’s new ScanR product is aiming to dramatically extend the range of engineering materials that can be laser-scanned with its latest green laser technology.

Offering ‘significant customer advantage over red and blue laser scanners’ for scanning highly reflective and carbon fiber parts, the technology is the sixth generation of the company’s CMM-laser scanners.

Highly reflective materials such as machined aluminum and carbon fiber composites have always required part spraying with a powder coat, which severely inhibits its practical use on repetitive production parts.

The new generation of ScanR 3D scanner should offer enhanced performances when needing to scan carbon fibre, polished metal or plated metal, with a wider coverage of the colour spectrum and reflectivity.

ScanR is integrated into Perceptron’s TouchDMIS metrology software, giving a ‘one-touch’ scanning interface and allowing initial user set-up using tactile-probe with subsequent sharing of the generated part coordinate system.

Feature extraction from the generated point cloud allows automatic inspection of part features against nominal feature definitions selected from CAD.

Production parts can be programmed to be inspected automatically with scanning zone and parameters adjusted per feature for data acquisition and cycle time optimisation.