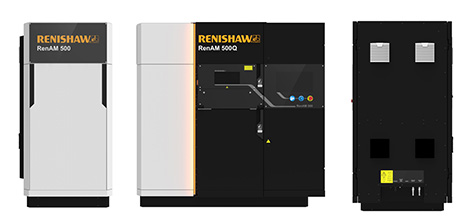

Featuring four 500 W lasers, Renishaw’s latest compact machine aims to greatly improve productivity in the most commonly used platform size for additive manufacturing.

More lasers in the RenAM 500Q mean faster build times, with the laser beams dynamically focussed and directed into a single, thermally controlled galvanometer mounting.

The galvo mounting houses four pairs of digitally controlled guided mirrors, which can guide lasers to cover the entire working area of the powder bed.

“Using the innovative design of the optical system and by incorporating digital controls and dynamic focussing, all four lasers can address the powder bed simultaneously – improving the speed, productivity and capability of the machine,” said Robin Weston, marketing manager at Renishaw’s Additive Manufacturing Products Division.

The machine itself benefits from 3D printed parts to allow for the control over the optics.

“It allows tighter packaging of mirrors and the incorporation of internal conformal cooling channels to maintain precise thermal stability,” explained Weston.

Additional emissions created by the increase in lasers are handled by an inert gas recirculation system, including a cyclone pre-filter and gas intercooler, which preserve filter life and provide consistent clean processing conditions throughout the duration of the build.