PTC has just launched a major release of its Product Lifecycle Management (PLM) solution, Windchill. Those that follow the PLM market will know that Windchill has become one of the leaders in the field since PTC acquired it in 1998.

From its genesis as a new breed of tool for managing the complex data, interactions and workflows associated with the product development process, it’s now on its 10th major revision.

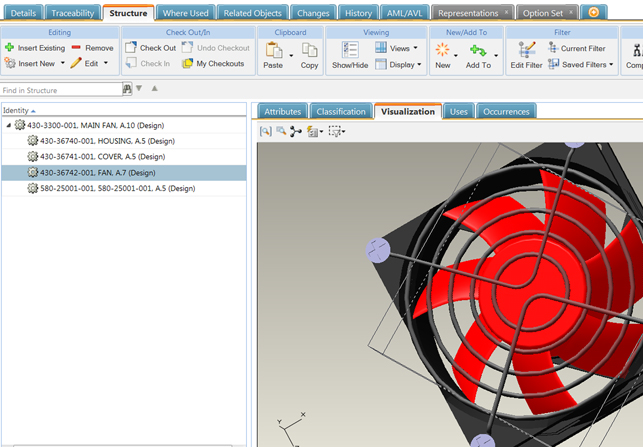

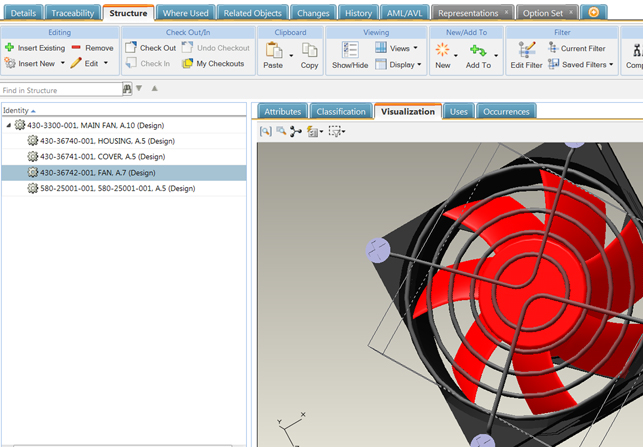

Users can select a component within the visualisation to identify a component within the structure

For those already engaged in using the tool, the biggest news is that Windchill 10.0 is much more streamlined with a customisable user experience. With a reputation for being ‘less than intuitive,’ users will notice a new interface that has been completely rethought in line with today’s expectations.

The focus of that redevelopment has been to allow customisation by both the enterprise implementing the system and those interacting with it daily. This means that each user can configure the interface to present the information they need, whether that be project updates or work items.

Richer product models = deeper knowledge

Alongside user experience, some of the biggest update work has been the increase in depth of the product data that can be managed within Windchill. The last few years have seen the company add support to not only the traditional 3D and 2D CAD data but the usual raft of documents as well.

The integration and management of electronics data was added a while back and 10.0 now enables the management of embedded software development information. Not only does the system manage development of the software (in terms of build, release and delivery), it’ll also integrate fully into complete digital models and their inherent product structures.

This ensures that the correct code is available and linked to the correct product, throughout its development. Windchill integrates with a wide range of today’s development platforms, including ClearCase, JIRA or more open source options, such as Eclipse, Bugzilla or Subversion.

Greater complexity vs customisability

For those involved in the development of complex products, Windchill 10.0 brings a raft of new capabilities intended to make life much easier. In the first instance, the system now allows the user to more effectively manage complex variants in their product range. It also allows for creating product variants long before CAD data is brought into the mix.

Through an intuitive interface, product requirements can be taken and product offerings created that accurately reflect complex variants, dependencies and configuration rules in a very short space of time. These Variant and Design Generation tools allow an enterprise to see exactly what’s being specified and worked upon, giving those responsible for programme management the tools they need. These can then be taken from what’s essentially a list of product features (and/or sub-systems) and options in the form of a Bill of Materials, and used to drive the design and engineering process.

This is backed up with greater support for large assemblies and tools for top-down design approaches that are associative to the eventual CAD structures. This means that not only can product configurations be more intelligent but, in subsequent projects, existing knowledge can be reused where needed.

Product Analytics

Analytics is a word that seems to have risen in importance over the last few years. It describes the application of computer technology, operational research, and statistics to solving problems in business and industry. Within the context of PTC’s PLM offering, it can be further broken down into taking the wealth of data that Windchill can manage and providing greater visibility of what’s going on with development projects.

The analytics tools introduced into Windchill 10.0 are found in four core areas. Three of those areas relate to tracking materials used within products, but each has a discreet function. At the core is Windchill Materials & Substances. This provides a central storage facility for all of the substance and materials content of parts and products. Those experienced in compliance will be aware that all materials must be stripped down to their chemical level or CAS reference.

On top of this, Windchill Compliance brings together the technology that PTC acquired from PlanetMetrics last year to build in tools to manage and report upon the compliance of products with a wide range of regulations and requirements, such as REACH and RoHS. Finally, on the materials front, the Windchill LCA (Life Cycle Assessment) manages and reports on the environmental impact of parts, products and supply chain.

Cost Analytics

Alongside these materials-related updates is the fourth arm to the Analytics products, which has the potential to provide much greater insight into the cost of projects and products.

This uses a range of tools that allows an organisation to define rough estimates at the very beginning of a project, and then add in more accurate costs as things progress.

What’s interesting is how this takes advantage of the BOM management tools to gain an insight into costs at both a high level and a very detailed view. When combined with the integration of 3D data visualisation tools from Creo Elements/View (as well as more traditional charting tools), anyone is able to see where costs lie, where they’re building up and where things are on track – in a very digestible manner.

Conclusion

PLM adoption faces several challenges outside of the age old question of enterprise level management. To make the most effective use of the system, it’s critical that users are engaged and the system doesn’t present a barrier. The work done at a core level means that users can customise the system and ensure they’re getting the most out of it from the word go.

Work done on areas that add depth to the system, such as the new embedded software development tools, means that everyone involved in the development, sales and servicing of a product, has a much more holistic understanding of the complete product. Considering today’s high-tech products across all manner of industries, the ability to have a single source of truth is ever more appealing. That single source is now not only for the geometry and documentation of the product, but also electronics and the associated embedded software.

The Analytics portions of the Windchill 10.0 update are intriguing. In the first instance, the Compliance and LCA tools are going to become increasingly critical for many organisations. If working within an OEM environment, the ability to centralise all of the materials and substance data pertaining to products, whether generated in-house or by suppliers, then interrogate them from both the compliance and environmental impact perspective, is invaluable.

Conversely, if you’re part of a supply chain, as most companies today are, these types of tools allow you to manage your own product’s data as well as effectively manage the data you’re supplying to your customers.

Windchill is a leader in the PLM world that enables the tracking of almost anything involved in the product development process. While its background is in 3D design and the associated data, Windchill 10.0 shows that PTC is expanding both what can be managed and what should be managed during a product’s lifecycle.

I’ve said for some time that, as today’s products become more complex, together with the increased complexity of their associated manufacturing and production environments, then we’re going to need a new breed of data management system that will ensure data is controlled, yet available, to everyone that needs it. With the 10.0 release, PTC has shown that it’s actively seeking out these new frontiers and building a system that tackles them head on.

| Product | Windchill 10 |

|---|---|

| Company name | PTC |

| Price | On Application |