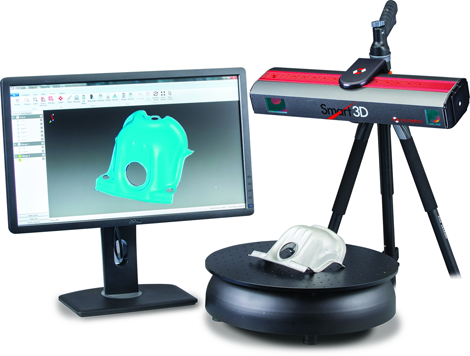

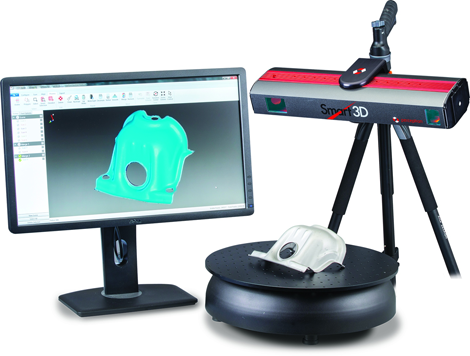

Perceptron’s new Smart3D system has accuracy to 50 microns

With the lofty aim of beginning a ‘revolution in automatic reverse engineering’, Perceptron has launched its Smart3D scanning system aiming to capture the 3D printing market’s attention.

Based on Perceptron’s Helix sensor technology that lets users programme laser line quantity, density and scanning volume, negating the necessity to physically move the laser scanner over the part, Smart3D comes with a fully integrated automatic rotary table and Scanworks Studio Software.

The system automatically provides STL models for reverse engineering, 3D printing or graphical web content, and can also be used for the verification of production parts against nominal part geometry data.

A ‘teach and repeat’ process allows scanning of repetitive parts using an Auto Rescan feature. The accuracy of the acquired dataset is significantly enhanced over equivalent data acquired using manually operated scanning systems.

All Scanning motion is contained within the Helix smart scanning sensor, that promises to dramatically improve the quality of scanned data while maintaining a volumetric accuracy down to 50 microns.

The unique configurable line density allows for scan line intervals programmable down to 0.1mm and further scanning optimisation.

The use of a coherent laser light source in the Helix provides a larger dynamic range allowing scanning of multiple colors and finishes. Elsewhere the laser’s dynamic range has been further extended by the incorporation of adjustable laser power control and dynamic auto laser intensity.

The overall scanning volume is 200 x 225 x 225mm which from the Perceptron release data seems to have been done to make the system physically compatible with the volume of most 3D printers.

The complete system is designed for easy transport with purpose designed equipment cases, and the ability for the scanner to work on a standard tripod, with a start up time reported to be under 15 mins upon arrival at the location.

The scanned dataset is streamed real-time into the accompanying Scanworks Studio data collection software with automatic full 3D STL model creation.