The new link-up means users can digitally and physically test optical prototypes – like car headlamps – from within the same ecosystem

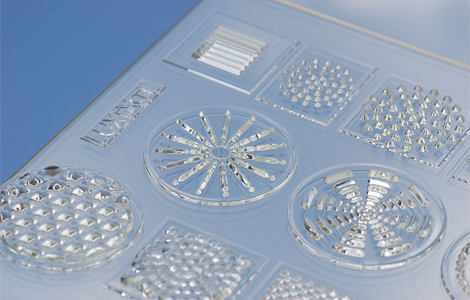

A partnership between visualisation specialists Optis, and 3D printed lens experts Luxexcel, is looking to offer a complete service covering both virtual- and real- prototyping solutions for optical components.

By enabling automotive designers to first created fine tune the lighting and optical designs of their future products digitally in Optis, the partnership will let designers create an accurate, clear 3D printed prototype using Luxexcel’s technology.

The Luxexcel material is now integrated in the Optis Library, looking to significantly speed up the design and prototyping process.

The 3D printing of clear optics is much faster and cheaper than the traditional methods

“After the customer designed his lens or light guide, he uploads and orders it online on the customer portal. We check the design, print it and finally ship it to the customer within 5 working days,” said Peter Paul Cornelissen, Luxexcel head of marketing.

“With this digital process we change a 3,000 years old analogue industry and make it future proof.”

The ability to 3D print different alternatives for a same component and to study them comparatively means designers and engineers can choose the best optics to suit a vehicle.

Customisation of products is fully flexible to adapt optical designs to the project’s needs and doesn’t require large upfront investments needed for traditional turning and milling. The process is also considerably reduced as the real prototype is available very fast, giving more freedom to create printable innovative shapes which are totally reliable.