MSC Software has introduced new interoperability enhancements between MSC Apex and MSC Nastran, with the implementation of a new Faceted Body Toolset allowing users to automatically regenerate geometry from meshes without the need for manual CAD model recreation.

“There is huge value in MSC Nastran engineering data for maintenance simulations or as a starting point for the development of new products, but the geometries for these models are often lost and topology modifications are time-consuming,” said MSC Software VP product management Hugues Jeancolas.

“MSC Apex is the first CAE tool to automate this, and we anticipate it could save hours for a single part – or days for an assembly.”

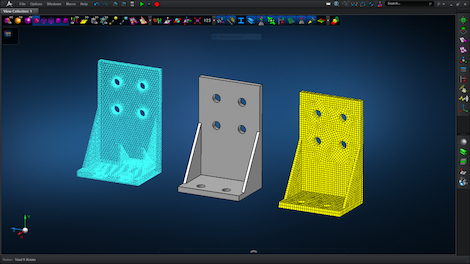

MSC Apex allows users to generate 2D and 3D geometry bodies from the definition of nodes and elements a legacy Finite Element (FE) model.

Users can import an MSC Nastran BDF file into MSC Apex and use the new Faceted Body toolset to create geometry from mesh in only a few clicks.

The geometry can then be further edited, performing Boolean operations and partitioning the body into cells to ultimately re-mesh it with proper element size and type choices.

The resulting geometry, mesh, and model attributes are all then generatively linked as a native MSC Apex model.

MSC Nastran models within MSC Apex can now be given ID management extensions, letting users access all parts, nodes, elements, and coordinate systems within a model through IDs and locate a specific object and manage renumbering efficiently in large assemblies.

These new features are available immediately to all customers in MSC Apex Iberian Lynx Feature Pack 2.