Using an Arcam electron beam melting system researchers say they can control the variations in crystallographic orientation in a nickel-based alloy

While 3D printed metals are still metals, there’s a structural difference between them and the stuff you get cast in the traditional sense, which is still worrying some people about part strength and consistency.

Researchers at the US Department of Energy’s Oak Ridge National Laboratory (ORNL) have demonstrated an additive manufacturing method to control the structure and properties of metal components with precision that not only matches conventional manufacturing processes, but goes even further.

ORNL researchers have demonstrated the ability to precisely control the structure and properties of 3D printed metal parts on a micro level during formation.

ORNL researchers have demonstrated the ability to precisely control the structure and properties of 3-D printed metal parts during formation

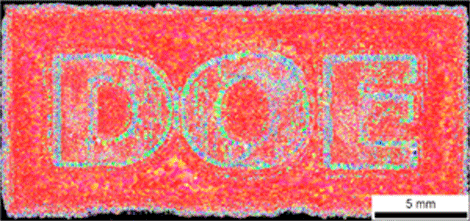

The electron back-scatter diffraction shows variations in crystallographic orientation in a nickel-based component, achieved by controlling the 3D printing process at the micro-scale

Ryan Dehoff, staff scientist and metal additive manufacturing lead at ORNL, presented the research this week in an invited presentation at the Materials Science & Technology 2014 conference in Pittsburgh.

“We can now control local material properties, which will change the future of how we engineer metallic components,” said Dehoff.

“This new manufacturing method takes us from reactive design to proactive design. It will help us make parts that are stronger, lighter and function better for more energy-efficient transportation and energy production applications such as cars and wind turbines.”

The researchers demonstrated the method using an Arcam electron beam melting system (EBM), in which successive layers of a metal powder are fused together by an electron beam into a three-dimensional product.

By manipulating the process to precisely manage the solidification on a microscopic scale, the researchers demonstrated 3D control of the microstructure, or crystallographic texture, of a nickel-based part during formation.

Crystallographic texture plays an important role in determining a material’s physical and mechanical properties. Applications from microelectronics to high-temperature jet engine components rely on tailoring of crystallographic texture to achieve desired performance characteristics.

“We’re using well established metallurgical phenomena, but we’ve never been able to control the processes well enough to take advantage of them at this scale and at this level of detail,” said Suresh Babu, the University of Tennessee-ORNL Governor’s chair for advanced manufacturing. “As a result of our work, designers can now specify location specific crystal structure orientations in a part.”

Other contributors to the research are ORNL’s Mike Kirka and Hassina Bilheux, University of California Berkeley’s Anton Tremsin, and Texas A&M University’s William Sames.