HP Metal Jet 3D printing technology has been unveilled

Metal Jet – HP’s metal additive manufacturing solution – has finally been unveiled, ready for orders and costing ‘under $399,000’ with shipping set to begin in 2020.

Designed for mass production, HP Metal Jet is a voxel-level binder jetting technology that prints ‘green’ parts using a speedy dual print bar system instead of individual lasers, before parts are removed and undergo post processing, including time spent in an industrial furness.

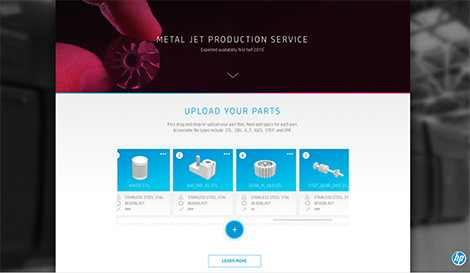

The launch system has a print bed size of 430 x 320 x 200mm, and will begin its life from today as an online service – printing stainless steel parts via the Metal Jet Production Service online order portal, from which HP states that the parts will then be produced by partners GKN Powder Metallurgy and Parmatech before being shipped globally.

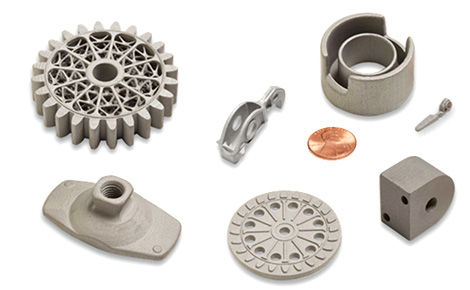

A selection of sample parts at launch – expect to see much more of the lattice-filled gear (top left) at launch events and trade shows this year

HP Metal Jet will be available initially as an online 3D printing service

Those taking the machines in-house from launch include Volkswagen, initially to assess the manufacturing of mass-customisable parts such as key rings and exterior-mounted name plates. However, Volkswagen‘s multi-year plan to use HP Metal Jet also includes the production of functional parts with structural requirements, such as gearshift knobs and mirror mounts.

“We are in the midst of a digital industrial revolution that is transforming the $12 trillion manufacturing industry. HP has helped lead this transformation by pioneering the 3D mass production of plastic parts and we are now doubling down with HP Metal Jet, a breakthrough metals 3D printing technology,” said HP Inc CEO and president Dion Weisler.

“The implications are huge – the auto, industrial, and medical sectors alone produce billions of metal parts each year. HP’s new Metal Jet 3D printing platform unlocks the speed, quality, and economics to enable our customers to completely rethink the way they design, manufacture, and deliver new solutions in the digital age.”

First Impressions of HP Metal Jet

Having teased us for some time, HP’s binder jetting expertise finally takes on metals – giving the company a blanket coverage of nearly all the existing 3D printing fields.

The key factor for this technology will be the speed with which short-run production can take place in order to take on established laser-powered technologies.

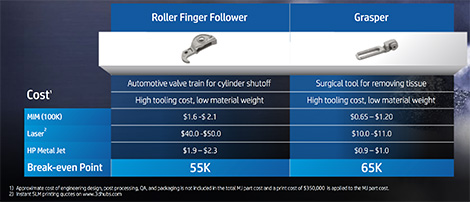

Adoption will rely not only on the design benefits of additive technology, as much as snaring companies that are looking for an alternative means of production for existing parts that have high tooling costs and low material weight, as the image below illustrates – break even points are temptingly close, even before design benefits are factored in.

Click image for more detail

The technology is not dissimilar to metal injection moulding, or to the 3D-printing-to-green-part techniques offered by Desktop Metal, XJet, and in some respects, the FDM technology used by Markforged’s Metal X 3D printer.

However, the sheer scale of HP as a company means that it has an accelerated development structure over rival technologies that are comparatively still in their infancy.

We’ve seen first hand how HP’s use of its MultiJet Fusion polymer 3D printing technology to fulfil its own manufacturing needs has provided a much needed testbed, but also feeds that key initial demand.

A two-year ‘internal’ production run process with partners should iron out any problems away from public view before machines ship to customers in 2020, while materials development will no doubt expand beyond stainless steel in that period.

HP’s Metal Jet technology (L) has speed benefits in the build process compared to SLM (R)

Peripherals are still to be unveiled – the launch showed no sign of the detachable build chamber, a clean-up post processing unit, or what factors might have been included to increase automation.

HP has stated it will not be producing its own dedicated furness for the process, instead choosing to find an existing partner, most likely from the metal injection moulding process.

This is an exciting technology that, once it reaches wider adoption and becomes more accessible, will likely have a noticeable impact on design and manufacture.