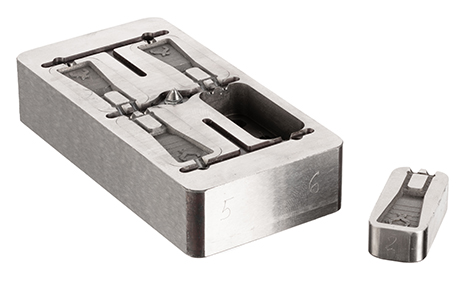

A mould for a zinc zipper tooling printed in H13 steel on Desktop Metal’s Studio System 3D Printer

Desktop Metal’s Studio System has added H13 tool steel to its materials portfolio, allowing the office-friendly 3D printer to produce mould inserts, extrusion dies, and sheet metal tooling.

Characterised by stability in heat treatment, exceptional hot hardness, and abrasion resistance, H13 is a tool steel widely used in hot work applications, but its toughness also makes it useablel for cold work tooling applications as well.

Ric Fulop, CEO and co-founder of Desktop Metal, said of the announcement: “This is a key competitive advantage to enable rapid iteration and refinement of tools requiring H13, and the reduction of manufacturing lead times.

The Desktop Metal Studio System

“Teams will also be able to achieve complex geometries that have not been possible with traditional manufacturing methods like machining.”

The launch was presented alongside industry use cases, including a mould for a zinc zipper for clothing.

The mould features numerous fine details, such as a company logo, textures, and subtle draft angles that are critical to the part’s moulding success.

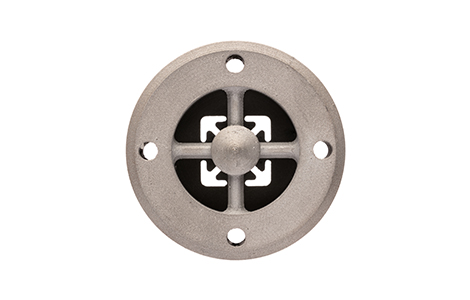

A complex geometry extrusion die 3D printed in H13 tool steel

The Desktop Metal Studio System high resolution nozzle can enable the fine details required for this part and also save valuable time and costs compared to traditional methods of machining the mould ready for die casting applications.

The Studio System materials library already includes 316L and 17-4 PH stainless steels, with more promised, including superalloys, carbon steels and copper.