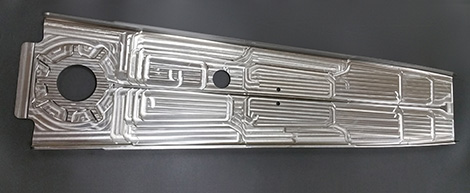

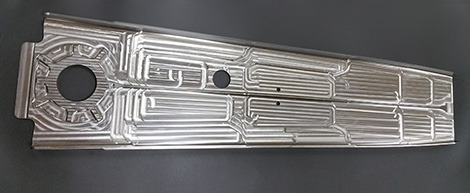

A part built by Airbus using Sciaky EBAM technology

Sciaky’s EBAM technology, its scaleable additive manufacturing method for giant metal parts, has entered into partnership with Concurrent Technologies Corp (CTC) – pushing the technology further into the awareness of manufacturers.

CTC is an independent, nonprofit, applied scientific research and development professional services organisation based in the USA, and will offer Sciaky’s industry-leading Electron Beam Additive Manufacturing (EBAM) metal 3D printing technology to its diverse range of innovative manufacturing clients who are looking to save time and cost on the production of large metal parts.

Sciaky’s EBAM systems can produce parts ranging from 8 inches (203 mm) to 19 feet (5.79 meters) in length, with rapid deposition rates ranging from 3 to 11 kg of metal per hour.

Major manufacturers, including the US Department of Defense, US Air Force, Lockheed Martin, and Boeing are already conducting R&D studies into the technology.

CTC has 20 locations across the US, with large-scale infrastructure capable of testing new technologies across a variety of state-of-the-art laboratories and large-scale demonstration facilities.

“Sciaky is excited to work with CTC and help educate its clients about the real-world benefits of EBAM technology,” said Scott Phillips, president and CEO of Sciaky, Inc.

“When compared to traditional forging methods, EBAM offers significant competitive advantages for customers all over the world by drastically reducing production time, waste, and costs associated with manufacturing large, high-value metal parts.”