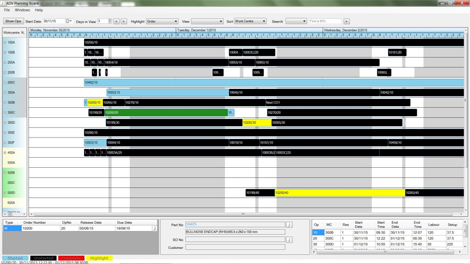

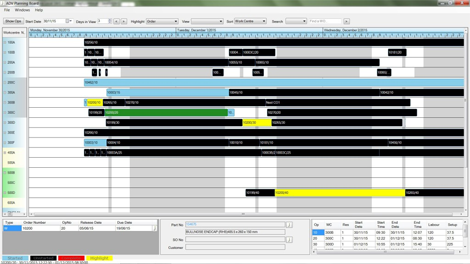

This could be your schedule of Tinder dates… or the advanced scheduling function for CNC jobs in Vero Javelin 2016

If you’ve just looked up after a long morning of scheduling the day’s CNC jobs, then this could be the news for you: Vero’s Javelin advanced scheduler is ready for the new year.

For 2016 its new Advanced Scheduling function claims to work to the nearest second, giving an accurate sequence of operations, instead of the daily capacity bucket offered in earlier releases.

The new system also looks to add more efficiency in handling nested operations, treating each one as a single step, meaning the next operation in the sequence can’t be started until all components in the complete nest have been manufactured.

However, an overlap function that allows a following operation to start before a previous one ends has been extended between components and assemblies – useful for if you’re making 100 components and you want to start the assembly process before they’re all finished. You can plan the assembly to begin after the first 10 or 20 have been produced.

With the Advanced Planning Board feature, the software not only shows the load going onto each work centre, but also gives the option to put operations into a different order, either by drag and drop or by keying in the start date and time.

If there’s a requirement to schedule something onto a different machine this feature allows the user to drag and drop the job to another machine with spare capacity, making full use of your machine tool resources.

Another addition to Javelin 2016 R1’s Advanced Planning board is that it shows jobs real time.

Multiple screens can depict a variety of details – including a weekly or monthly view, along with other limiting factors such as labour force available.

A direct link to Vero’s sheet metal CAD/CAM software should allow Radan nested material optimisation to be applied to a Javelin nest, with full visualisation of the proposed sheet layout, allowing manipulation of the nest contents to improve material utilisation prior to committing to CNC code.