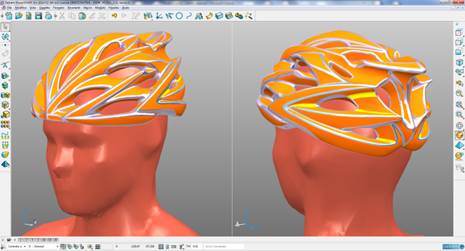

An aluminium version of the Rudy Project’s Windmax Helmet being created out of alluvium on a Mazak machine

A shiny incarnation of Rudy Project’s Windmax Helmet, has been milled in aluminium by Delcam to show off its reverse engineering capabilities.

The Windmax helmet is the choice of the Delcam-sponsored cycling team at the Italian manufacturer Progetto Cycling.

Although Rudy Project is not a customer, Delcam Italia general manager Franco Calloni approached the Italian company with the request of using the helmet to promote the Delcam Solution: Reverse – Milling – Inspection.

Delcam’s PowerSHAPE software was used to reverse engineer the helmet

In order to achieve his vision for an aluminium helmet, Calloni called on a number of technology partners. First of all a Faro Gage from Metrologia was used for scanning and inspection.

This scan was then brought into Delcam’s PowerSHAPE solution.

A prototype was created with a CMS CNC router

Other solutions used during this reverse engineering process include: a Comau robot, CMS router, Isper machine tool and a Mazak Variaxis j600-5AX.

The end result is an impressively shiny and very accurate aluminium helmet, that Delcam will be showcasing at its stand at the forthcoming Bimu exhibition, an automation trade fair taking place in Milan, Italy, from 30 September to 4 October 2014.

For a whiz through the process, watch the video below.

//www.youtube.com/embed/yYGqMsFnu4M