Parts can now be mirrored in PowerMill 2016

The 2016 version of Delcam PowerMill CAM for five-axis and high-speed machining is set to come with the ability to mirror complete machining projects in one operation and automatically maintain the machining characteristics.

This new feature should allow users to choose automatically whether climb or conventional milling should be used in each section of the toolpath, where previously, only individual toolpaths could be mirrored.

The new function should save considerable time whenever right- and left-hand versions are needed of a part or tool, and potentially making it faster to program the machining of symmetrical objects since it will be possible to program one half and then mirror the toolpaths to complete the program.

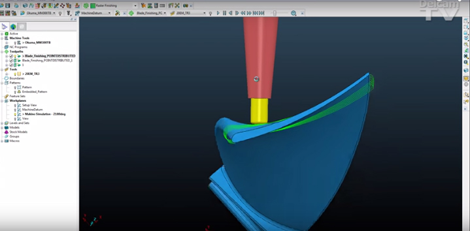

A new efficient strategy to machine single blades has been developed for PowerMill’s Blades, Blisks and Impellors module

To ensure that the mirroring has performed as expected, the new option can be used with the ability, introduced in PowerMill 2015 R2, to undertake complete verification of a project for machine-tool issues such as collisions.

Comprehensive verification is said to be available, including ensuring that the machine tool is capable of running the mirrored toolpaths, as well as checking for both machine-tool collisions and tooling collisions.

PowerMill 2015 R2 also saw the introduction of the ability to simulate machine-tool movements as tool changes are executed, which has now been enhanced in the 2016 release by allowing more complex tool changes to be simulated, in particular those involving a carousel mechanism.

Other improvements to simulation in PowerMill 2016 include a new form to print out the position of the cutting-tool tip during simulation, an auto-translucency option that will allow viewing of the table attach point at all times, and the ability to draw translucently the safe areas for rapid moves.

Development work has continued on the optional modules for PowerMill as well as to the main program. In particular, a new, more efficient strategy to machine single blades has been developed for the Blades, Blisks and Impellors module, and a constant-Z machining option has been added to the module for programming the machining of ribs into tooling.

The R2 release of PowerMill 2016 is already scheduled for March 2016.