Since being acquired by Tier 1 aerospace manufacturer Premium Aerotec, APWorks has not slowed down its efforts, releasing AMXpert, a new online software platform for additively manufactured metal parts.

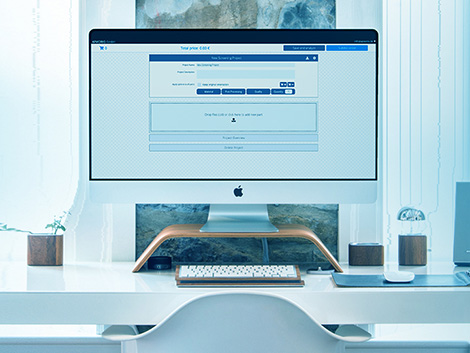

The software is a direct online order system, offering a complete digital process chain, aiming to let users validate and order their 3D parts via APWorks, combining part screening for identifying suitable parts for the process, cost analysis, printability checks, and an end-to-end order process.

AP Works says that based on print job data and machine learning algorithms each uploaded part will be automatically assessed and positioned in the ideal orientation for 3D printing.

There’s a choice of high-performance materials, including AlSi10Mg, Scalmalloy, Ti6Al4V, and 1.4404, with post-processing steps varying between heat treatment, machining, and a surface finish.

Most importantly, given the high level of scrutinising required for industry, APWorks offers tests including CT Scans, 3D Scans, and much more. Additionally, the qualification process involves test series required for qualification certificates such as CoC or EASA Form 1.

“Virtual technologies and additive manufacturing are enabling the industrial world to achieve more while producing less waste, weight, and costs, as well as freeing designers to explore complex shapes that could not be manufactured using traditional processes,” said APWorks managing director Joachim Zettler.

“AMXpert is fast, intuitive and beneficial. By enabling a fully digital process chain in one tool, from part screening and analysis, to optimisation potential assessment, to price calculation and the online order process, it truly brings additive manufacturing to the next level.”

The prices quoted online cover the costs for the entire metal additive manufacturing process, including printing and costs for various metals. Additionally several post-processing steps and qualification processes can be integrated as well. It is furthermore possible to specify a requested delivery date to enable a priority production time, and to provide customers with real-time updates on the order status of their parts.