Fashion technology company Alvanon has announced a new collaboration with sportswear giant Under Armour (UA) to inspire fashion brands to further embrace 3D deign tools and software.

The two companies partnered on a project to develop new 3D tools, particularly working with 3D avatar size sets, to make better product, with improved sizing and standardisation, that delivers next-level accuracy and fit for the consumer.

Many companies, including UA, have turned to 3D virtualisation to significantly reduce the time and cost of product design and development – aiming to minimise the laborious and slow physical sampling stage.

Prior to the 3D collaboration, UA partnered with Alvanon to sculpt all of its physical fit forms to the company’s proprietary fits.

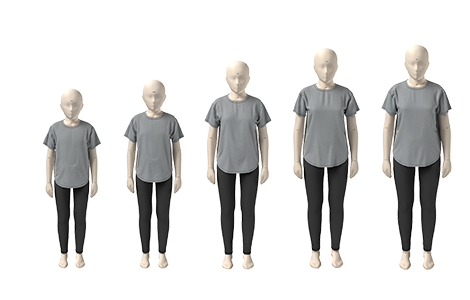

With the new collaboration, Alvanon built on those fit forms to create a range of digital avatars for UA, replicating its proprietary fits and representing the full spectrum of ‘real’ bodies across men’s, women’s and kids.

“When we fit product on fit forms across the size scale, it does not always follow a mathematical equation of traditional grading,” says Jami Dunbar, Under Armour VP of apparel and accessories development and supply chain operations.

“One of the things working in volume allowed us to do is consider a lot of different body shapes,” she said, adding: “Now we can move confidently in 3D to fit bodies.”

“Today’s consumers expect apparel to fit and look good on them at every size. That’s where 3D can help,” said Alvanon senior consultant Tracy Rickert.

“Whether you’re using ASTM parametric or custom we believe these virtual assets (standard avatar size sets) will help brands and retailers resolve their sizing issues much faster.”

UA has also acted as an instrumental beta partner in Alvanon’s recent development of the Alvanon Body Platform, which allows brands and retailers to access and share their 3D fit and core body standards with supply chain partners.