It’s been a couple of weeks since I got back from Texas and the PLM Connection event held at the beginning of last month – but I’ve got a few thoughts and whatnot to share from the event. This was the first time that the press has been invited to the event and I was curious to find out what it was like, what the feeling was amongst the users in attendance and of course, to catch up with the folks at Siemens.

PLM Connections is organised by the user group committee, many of whom I got to meet on the first day. It’s clear that this is a user focussed event and the attendance and subject discussed reflects that. There’s often a difference between user events organised by the users (or a group of them), such as this and PTC’s PTC/User events and those organised by the software vendor (think SolidWorks World). It’s quite difficult to put a finger on the different between the two, but there’s something. Whatever it is, both types are focussed on three things: Learning, Updating and Networking.

The learning is satisfied by just under 400 technical sessions that reach across the entire Siemens portfolio – while the event began as an NX (or Unigraphics) focussed event, it now brings together those users with those from the Teamcenter, Tecnomatix and Solid Edge communities. What I found interesting, speaking to a number of both the organisational committee and the users in general, is that they’re typically there for an update on several items from that list – predominately NX and Teamcenter, but the others get a good look into the mix.

Perhaps the big difference between this and other larger events such as SolidWorks World and Autodesk’s Autodesk University, is that it’s a pure user event and one that’s focused on a single community of users engaging in related industries (namely, design, engineering and manufacturing). AU is a mix of engineers, architects, civil engineers, all manner of things, so you get bigger numbers, but less focus. SolidWorks World on the other hand, focussed on the SolidWorks community, but also brings together a user event alongside a VAR event – so while the attendance figures might be three times higher (around 6,000 people), estimates vary that between 50% and 66% of those are partners, VARs and staff.

SIemens PLM CEO, Tony Affuso. He reads DEVELOP3D according to the presentation. Which is ace.

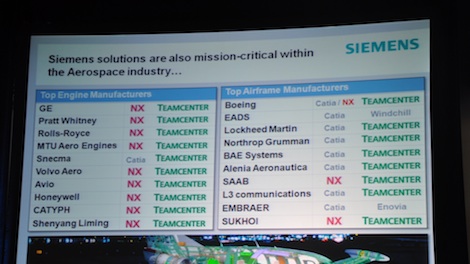

In terms of updates, the keynotes are an excellent place to start. This year saw Siemens PLM CEO, Tony Affuso take the stage and deliver an update on where how the company is performing and where its headed. One thing to consider is that as part of Siemens AG, the PLM division isn’t reported upon separately, so the facts and figures Affuso showed come with very little in the way of real-data. What are hard facts are that Siemens looks to be performing well. It’s added 4,000 new customer sites in the last 12 months to bring the totals up to 68,700 customers (that’s customer sites, rather than users) and 6,600,000 seats deployed (the majority of which are going to be Teamcenter related). One slide was intriguing which detailed Siemens’ presence in the aerospace industry. While there it showed a good mix of both NX and Catia, it also showed that Teamcenter was pretty much everywhere, with the big exceptions being EADS (who recently moved to Windchill) and Embraer.

Teamcenter and NX deployment in Aerospace

Following the corporate update, Affuso was joined by Helmuth Ludwig (Siemens PLM President), and Chuck Grindstaff (Siemens PLM’s CTO) to show what they’ve been working on. The one thing that jumped out was a look at how the HD-PLM platform is shaping up. While we’ve discussed at length the user of HD-3D within the environment of NX since its launch, where visual reporting tools are combined with metadata and other product information to create a highly engaging, graphically led environment for inspecting all manner of information, HD-PLM extends this further to encompass all of the tools in the Siemens PLM portfolio.

As you can see from the screenshot above, it presents this information in a manner that anyone can understand and interact with. Products are complex today, more than ever before, as are the environments in which they’re developed – and we need a new breed of tools to deal with, collate, rationalise and present that highly complex data in a manner that’s unambiguous and clear. HD-PLM is Siemens platform for delivering just that.

Bob Trecapelli, Director, Digital Innovation /PLM/EPIC at Ford

To highlight just how complex things are getting, Bob Trecapelli from Ford detailed just how complex Ford’s product ranges are and how the company is looking to both expand its offerings, but also to rationalise the platforms and vehicle programs it has. At present the global vehicle market is split three ways between the Americas, Europe (and others – presumably middle east, africa, russia etc) and Asia Pacific. But looking forward to 2018 the major increase is going to be in Asia, with a heavy increase in units (we’re talking 10s of millions of units more growth). To remain competitive in this rapidly changing market, Ford is looking to make the most if platform sharing and reduce its core platforms. in 2009, the company had 25. by 2014 (only four years away), the goal is to have 11 and to have 91% of its vehicles built on those core platforms (compared with 50% today).

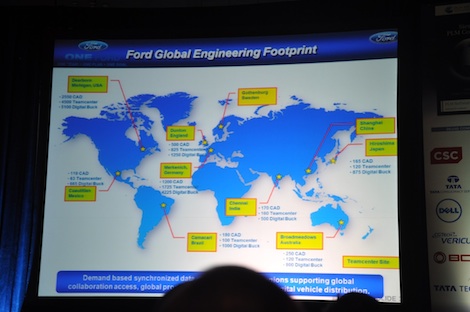

How Ford’s global organisation stacks up

And to achieve this across an organisation that has 5,100 CAD users, 7,600 teamcenter users, 14,500 consumers of that Teamcenter data, 310 direct suppliers (tier one I assume) and 500 distributed digital vehicles, you’ll see why this is going to mean not only a new approach to how the vehicles are developed, but also a new breed of tool.

Alongside the keynotes and technical sessions, the partner exhibit is always an interesting place to spend time. its here that you really get an idea of what challenges the attendees are facing and what solutions are being developed to solve those problems. While smaller than the exhibit halls at other events, it was clear that there’s an interest in both data exchange and quality both in the design process and within the manufacturing world. One company stood out in terms of “cool factor” and its a company I’ve had very little contact with for nearly a decade. BCT has been developing applications for the Unigraphics, then NX/Teamcenter world for many years and has built a reputation for solid tools. They’ve just launched an iPad app that allows you to interact directly with Teamcenter. Have a look at the video below and tell me that the iPad is just a toy now:

Final thoughts

I didn’t know what to expect from PLM Connection. First time I’d been invited, but I was keen to attend. It’s only when you sit amongst the users of a particular vendor’s tools and engage with them face to face that you get a sense of what challenges they face. That then gives you a good indicator of why a vendor is doing what its doing. From speaking to the attendees, the one key take away for me is that complexity is an issue. Complexity of product geometry, complexity of data exchange, complexity of a globally distributed supply chain and outsourcing. That’s feeding into the Siemens PLM development process and you’re seeing the results manifest themselves in the products, in Teamcenter, in NX and Solid Edge, in the partner applications that surround them. and I find that fascinating. Several vendors are off pursuing things that are new, tangentially proven in terms of deliverability, but leaving the core products they delivery alone or incrementally tinkering with them. Maybe its a reflection of the users demands or complacency on the part of the vendor. Maybe its a need to find new ways to extract revenue, I’m not sure, but I would much rather see a set of tools coming from a software vendor that look to solve the challenges that face its customers now and in the future, rather than staring into the clear blue yonder. That’s what Siemens PLM does best.

And from speaking to many of its users, they’re happy. Yes, they have things they want or need, but i didn’t hear a bad word against the company. No whinging, no whining, just a will to learn and a will to share. For me, that makes this event quite marvellous.

If you want to join the PLM World organisation, membership is free, as long as you work for a company that licenses Siemens PLM software, you not work for a competitor to Siemens PLM and you can apply here (http://plmworld.org/membership/). Next year’s event will be at the Rio hotel in Vegas, should that be an incentive, rather than a barrier. Personally speaking, if I were working with the Siemens tools, then I’d consider attending the event, there’s much to learn, both in terms of getting a view of where Siemens are headed with your critical toolsets, both in the short term and longer term, but also, the chance to interact with your peers is something that can be incredibly valuable.

Oh and if you want to ‘see’ what else I thought about the event, you can see me mumbling like an idiot to Siemens PLM’s Social Media Maven, Dora Smith in this Youtube video.