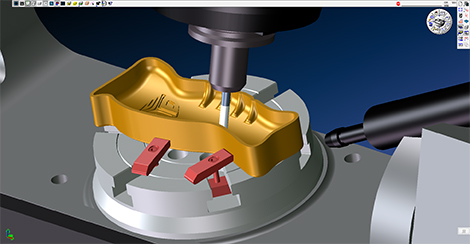

GibbsCAM 2016 is designed to help users eliminate scrap and reduce cycle times

The latest version of GibbsCAM CNC machining platform introduces a range of new speed and simulation improvements as it looks to enhance the link between its parent company’s interests in 3D printing and end use parts.

3D Systems suggests that GibbsCAM’s ‘enhanced kinematic framework’ makes it a versatile CAM platform that complements the additive manufacturing processes which its parent company has a firm grounding in.

Compatible with a wide range of programming and machining operations, including solid modeling, high speed machining, 2- to 5-axis milling, wire-EDM, multi-task machining and more, GibbsCAM is designed to help users eliminate scrap and reduce cycle times.

//giphy.com/embed/ui5WlZJeKNu4U

New features and functions of GibbsCAM 2016 include:

– Enhanced thread milling, including support for multi-point tools, tapered threads for both single- and multi-point tools, and improved simulation

– The latest VoluMill technology, providing new toolpath strategies to optimise high speed roughing of large pockets and slots, open face milling strategies

– New oriented turning capabilities – from using a single tool at multiple B orientations to reorienting tool groups for use on a different spindle to full support of Flash Tooling for multiple-orientation turning tools

– Added toolpath strategies for 5-axis milling, enabling users to define toolpath direction using the natural flow of a surface with the new Flowline option