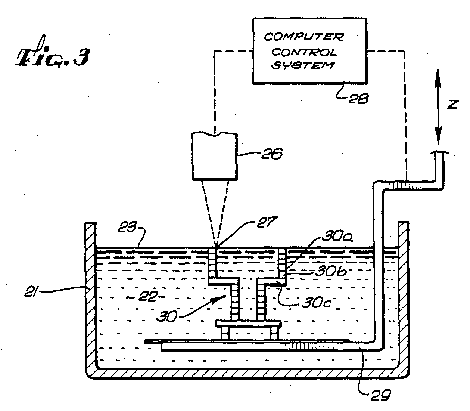

3D Systems is a fascinating organisation. They kicked off the rapid prototyping industry when Chuck Hull invented and commercialised Stereolithography (SLA) technology and brought it to market in 1986. This, for those unaware, uses a combination of lasers and higher-end optics to cure layer after layer of photo curable resin. It also developed the STL format that’s become synonymous with rapid prototyping as the means of outputting triangulated meshes from your CAD system.

As many involved in rapid prototyping will know the industry has been through rapid development in the last 6 or 7 years. Materials have very quickly advanced from brittle, UV sensitive materials into true wonders of material engineering. Look at the Bluestone material, again a photo-curable material, but it’s a nano-composite that delivers incredible stiffness and exemplary surface finish.

Along the way, there have been interesting diversions. The company acquired Desktop Factory a couple of years ago, a company that seemed to flounder on its promise of bringing truly desktop, affordable 3D printing to market. It also experimented with new process, such as the Optoform process, which uses the same laser+optics process, but to cure very stiff ceramic material – I saw one of the beta test machines at Renault F1’s head quarters and the parts it built were incredible.

But the company seems to be doing something that many are talking about and many can’t quite puzzle out. Over the last year, the company has been on a spending spree of epic proportions. Let’s look at a list of who the company has acquired. There’s QuickParts. Not a service provider per se, but rather an organisation that brokers work out to other bureaux with the machines. There’s Express Pattern who specialise in the production building patterns for investment casting and manufacturing. Over in Europe, it acquired, Provel, one of Italy’s leading rapid prototyping, tooling and manufacturing organisations that can handle Stereolithography, Selective Laser Sintering, Rapid Tooling and Urethane casting.

It’s clear that the company is planning to move into the services industry heavily, as 3D printing, direct manufacture or whatever you want to call it, takes off. The company even acquired National RP Support, a company that provides a support service for 3D Systems’ equipment – one of a number of companies that do exactly that.

Then things get interesting. The company has also acquired Bits from Bytes. A company that has built a reputation on manufacturing very low cost 3D printing systems, aimed fairly and squarely at the consumer and educational market. With the rise of low cost 3D printing hardware such as the MakerBot, the Personal Portable 3D Printer, this was a smart move.

Then it gets even more interesting. The company has recently acquired three companies that show where the organisation is heading. The first is Freedom of Creation. A Dutch organisation that has been one of the leading proponents of direct or additive manufacturing. With a pan-European team of designers, the FoC has been creating a huge range of products from lampshades, through furniture, higher art and of course, the now ubiquitous iPad and iPhone cases.

It also acquired Sycode and Print3D. Companies owned or part owned by my old friend, Deelip Menezes. What’s Deelip known for (apart from his blog, air-miles and crap photography skills)? Tools that can take 3D CAD data and convert it into STL. What does an RP machine use? STL. That’s interesting. It also acquired content sharing and sales portal The3DStudio.com.

So what the hell are they up to?

The company switched its strap line to “a leading provider of 3D content-to-print solutions” some time ago (thanks Rachel). But what does that mean? To my mind (and note, this is pure guess work), it means this:

The rapid prototyping world as has been existent for the last 20 years, is reaching a point of dramatic shift. 3D Printers are popping up every month and there’s not the huge range of legal action that would have ensued 10 years ago (3D Systems aren’t afraid to use their lawyers).

Why is that the case?

The answer is that many of the core, fundamental patents that protect founding companies such as 3D Systems and Stratasys, are coming up to expiration. That means that once the IP protection is lessened or perhaps gone, the competition, whether existing or new entrants into the market, can run riot. Companies like Stratasys and 3D Systems have survived by bringing innovative products to market but doing so in the rarefied atmosphere of patent heavy protection and very little competition. Once that bubble pops, it’s Game On.

Patent Number: 4575330 – Issue date: Mar 11, 1986 – This is Chuck Hull’s core sterolithography patent describing the process.

We all know that many RP machines are pretty basic. Yes, the SLA process is complex with its range of lasers, optics and the like, but things like FDM are already being replicated and improved upon (in terms of price/performance) and many of the old guard of rapid prototyping vendors can’t keep up. But even the laser/optics combos are getting some attention from the younger generation hackers. There’s a team at the University of Vienna working on a very small form factor 3D printer that recently made the rounds of the tech blogs.

The “World’s Smallest 3D Printer” by the team at TU Wien.

So what have they got? Let’s recap.

- 20 years of 3D printing experience, ranging from the sub 1000 euro to huge industrial scale machines.

- Expanded team of service and support staff.

- Greater extension to its manufacturing support. Not just SLA, SLS or 3D Priniting, but batch manufacture with vac casting and such.

- Data translation and CAD interoperability knowledge.

- Established and functional 3D content portal.

For me, the list above looks interesting and lists out a company that’s looking to take on the manufacturing industry by growing in both breadth of service offerings across the globe. It has the reach, the support network and a distribution model for the professional end of the spectrum with its existing 3DProParts service offering and those gained through QuickParts. But what about the rest of the world, what about the mainstream? The thing that put it all into context for me was the acquisition of Freedom of Creation.

If you’re looking to make a statement that you’re a leader in a field, then you need to have a showcase of products that are leading the way. That’s what Freedom of Creation bring to the table. In a year or whatever it takes, 3D Systems will have a global manufacturing capacity, presumably backed up by the hundreds of service bureaux it already has machines in place at. It has the potential to build a back catalogue of not only higher-end products from the likes of Freedom of Creation, but also the community built 3D models from The3DStudio.com

That means that as 3D printing becomes more mainstream, as the general public (as opposed to the professional user) becomes more aware of the ability to direct manufacture its own parts and products, it stands to be ready. With content to lead those that don’t have the desire or ability to model their own. Many have been predicting the rise of mainstream 3D printing for many years, but are we on the cusp of it actually happening? Looks like we are. The only question is: who’s coming along for the ride?