The ATOS ScanBox allows for highly detailed scanning with a simple interface

Automation in the everyday working world is a beautiful thing – let a robot take the strain while you put the kettle on and eat a Twix – but sometimes the technology could be used elsewhere.

3D scanning experts GOM introduced its ATOS ScanBox 4105 earlier this year, effectively a kiosk containing a compact, robot driven ATOS Core 3D scanner, with a turntable and inbuilt processing computer, used for automated measurement and inspection of small to medium parts and components.

The Virtual Measuring Room is the central control station and measurement planning software for all aspects of the process, removing the requirement for specific robot programming skills, meaning a simple and safe software interface most people can easily manage.

//www.youtube.com/embed/C4cfv9AqJ8A?rel=0

Although meant for scanning in hi-res 3D data for engineering components, for inspection or as part of the reverse engineering process, we’re convinced there’s a world of uses for such advancing technology.

Previously we’ve seen how museums are desperately trying to digitally record their artefacts, either for preservation, restoration, or simply to make a catalogue of 3D models available via the internet.

With hundreds of thousands of objects in each museum, most currently being done by their everyday staff, curators, or interns letting a machine handle the measurements automatically could easily be the best way.

As human interaction is reduced, high precision and data quality are guaranteed, and measurement parameters, data and operating system are protected from costly accidental human error (scanning hundreds of fragments of ancient pottery each day = mind numbing).

Imagine a conveyor belt set up, with each part coded and logged, meaning the only handling is packing away the items once scanned?

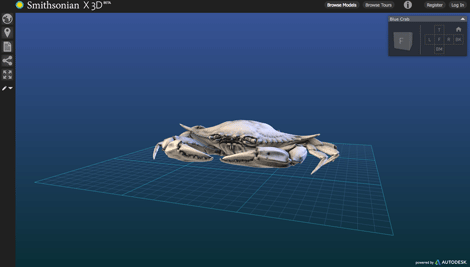

The Smithsonian Museum’s efforts to catalogue its millions of artefacts – including biological samples such as this Blue Crab – could benefit from scanning automation

Currently there is some expansion in the way the data is being used. In the US, the Smithsonian is attempting to scan its millions of artefacts, setting up X3D – its digital department – along with Autodesk. The Museum of Liverpool used 3D scanning to produce replicas of objects so that school children could have more hands-on learning.

The British Museum in London is experimenting with ways of using digital devices to bring small objects to life, and more understanding to its most ancient Egyptian artefacts.

Elsewhere, as the world clambers towards the next generation of digital devices and virtual reality, having a station to scan high quality surface data without need for training or personnel would be a massive benefit – whether for medical use, data input for video games or simply more standard engineering uses.

The idea of it being a simple self-operating kiosk immediately makes the technology more approachable – like the old quote says: nobody wants to know what goes into a sausage, they just want to eat it.

Will we see them in shopping malls? Feed in a few coins into the slot, pop your pet terrier onto the turntable to be scanned then 3D printed, or an antique vase you want to send away digitally to be valued?

Probably not, but as rumours swell about the next generation of smartphones having inbuilt low resolution 3D scanners, there’s going to be increasing demand for higher resolution detail, and not simply for inspecting sprockets.