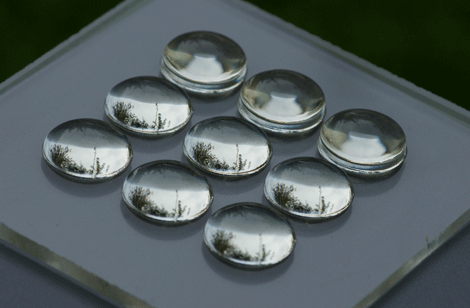

The new ‘LUX-Opticlear’ material means that the process might ready to compete with injection moulding

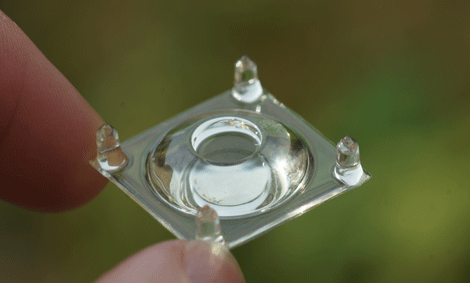

A revolutionary method and new clear polymer for making optical components using 3D printing is enabling the production of high quality optics manufacturing up to 20mm in height.

Dutch specialists, Luxexcel Group, states that its new material ‘LUX-Opticlear‘ means that its process is ready to compete with injection moulding for small and mid-sized series’ of optical components, cutting out the need for tooling and lengthy post processing.

Customers will be able to access the technology from Luxexcel’s new online platform, which enables the uploading of various different types of CAD files and automatically re-processes the CAD data into specially formatted print-files.

No tooling and limited post processing means the speed benefits for producing small series’ of lenses this way

”The optical quality of the new LUX-Opticlear material combined with the digital advantages of this new additive process, makes our service an affordable and attractive solution for both prototyping and smaller or mid-sized volume manufacturing of optical components” says Richard van de Vrie, founder and CEO of Luxexcel.

“As we do not need to post process the printed products, our process is fast and scalable, enabling optics designers to walk a perfect route from fast prototyping and easy iterating, to manufacturing the exact required volumes in days.”

//www.youtube.com/embed/sEDsCx9bV5A?list=UUfjY_NTQ-DpXAPkwRPwiqeA