With her maiden voyage now under her belt, Wonder of the Seas is preparing for a busy 2022. At shipyard Chantiers de l’Atlantique, engineers explain how CAD integration with digital twin technology helped to turn this complex design concept into competitive advantage

Wonder of the Seas is exactly as described – an engineering marvel. At 362 metres in length, and weighing in at 236,857 gross tons, the world’s largest passenger ship boasts a cruising speed of 22.5 knots.

The ship was built by Chantiers de l’Atlantique in Saint-Nazaire, France. The company is one of Europe’s most renowned shipyards and the name behind some of the world’s most legendary ships, including the SS Normandie and the Queen Mary 2.

“At our yard, we are aware that we have designed and built one of the most exceptional ships in the history of the cruise market,” says Laurent Castaing, general manager of Chantiers de l’Atlantique. “Wonder of the Seas is a unique synthesis of innovation, state-of-the-art technologies and the savoir faire of thousands of engineers and skilled workers.”

The numbers are incredible. Wonder of the Seas’ 18 decks contain 2,865 staterooms, capable of handling up to 6,988 passengers, as well as 2,300 crew. There are 24 elevators, 20 restaurants and 35 bars, not to mention water parks with giant, swirling, deck-to-deck slides, a zipline, theatres, a casino and climbing walls. One of the special features on board is the Central Park, home to over 10,000 real plants.

Construction began in April 2019 and cruise line Royal Caribbean took delivery of the ship in early November 2021. Against a backdrop of pandemic-related delays, the delivery timeline was as impressive as the ship’s size and amenities.

“Harnessing complexity for us is a matter of process,” explains Yves Pelpel, technical director at Chantiers de l’Atlantique. “This is especially true for engineering. We have a robust process that we have developed over a number of years. In terms of competitiveness, the more complexity we have, the happier we are because it will be more difficult for Far East competitors to enter the market.”

Wonder of the Seas // Smooth sailing

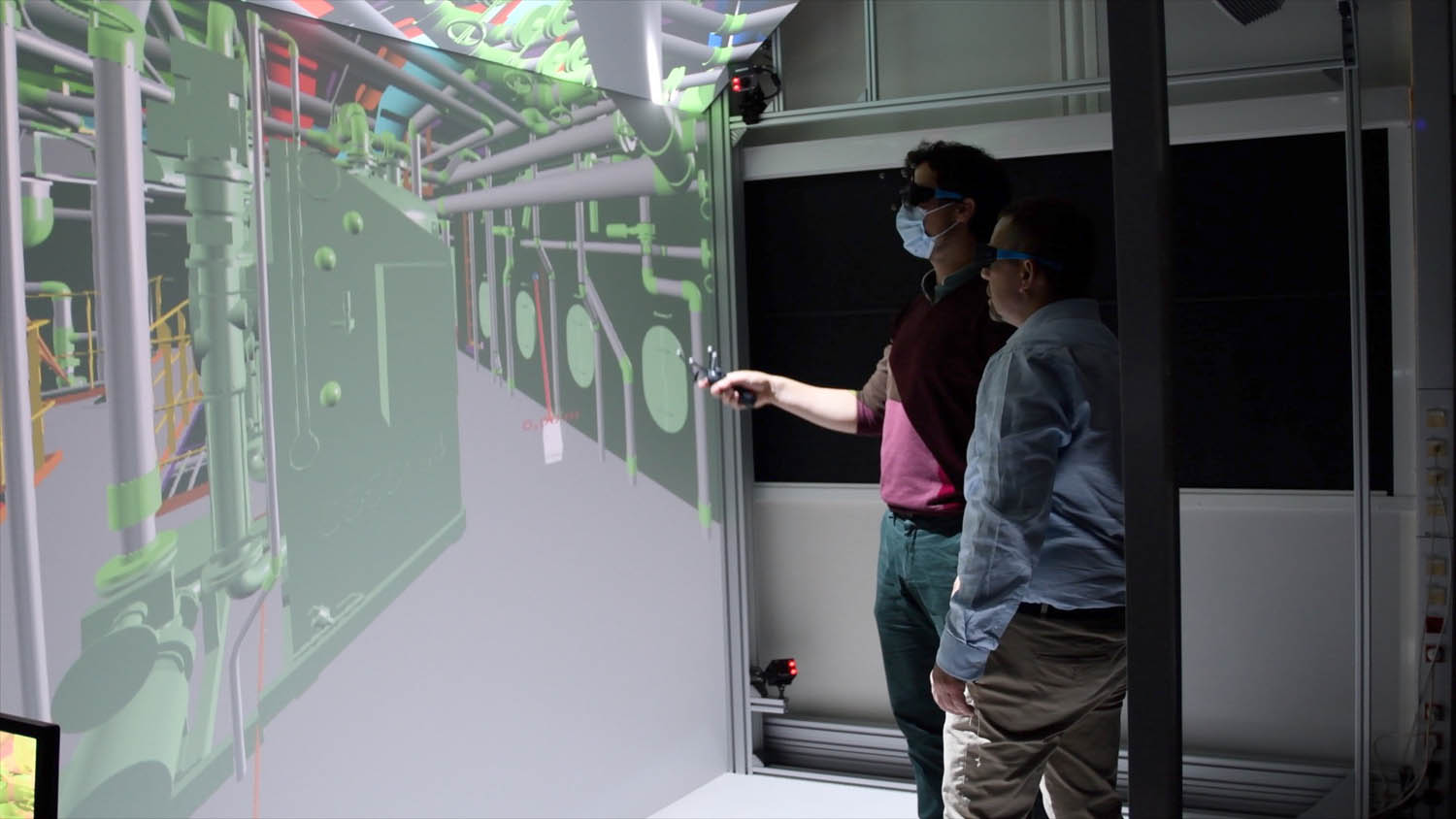

One of the key ways Chantiers de l’Atlantique manages complexity is by using a customised, integrated digital twin built in Intergraph SmartMarine software. The CAD system is directly linked to its SAP enterprise resource planning (ERP) system, which contains the entire structure, its piping, HVAC and cable trays. “

Around that we have different tools connected with that system,” says Pelpel, explaining that this keeps the company one step ahead of its competition, allowing it to undertake pre-outfitting and conduct engineering phases in advance.

Immense as the digital twin is, the entire model is updated nightly, so that all stakeholders are working with the correct data and information.

Like most ships from Chantiers de l’Atlantique, Wonder of the Seas contains millions of parts, thousands of components and a huge variety of finished products, ranging from the floors of prefabricated cabins, elevators, engines and HVAC systems, to water slides and swimming pools. All this needs to be designed and integrated in the digital twin before it is integrated into the physical vessel.

During the process, hundreds of designers, engineers, integrators and production specialists work on each project. To manage this complexity, the entire company works on an object-centric process following the bill-ofmaterials (BOM) throughout the workflow.

“From the initial design to building the ship, we want to stay object-centric,” explains Sébastien Blanchard, PDM and CAD manager of Chantiers de l’Atlantique. “We have a system with an automatic BOM and we directly go from the 3D model or the 2D model in the CAD system to the ERP every night.

“For one ship, we send nearly 100,000 parts in our BOM from the 3D model to the ERP system every single night. This is the only way that everyone involved can be up-to-date.”

Cabin fever

To fit out the thousands of cabins onboard, Solid Edge is used, with each prefabricated layout tailored to the personality of each individual ship. Solid Edge is used to design and verify the initial integration of the cabins into the vessel via the SmartMarine digital twin. This is an important part of the ship’s design and requires many iterations between teams at Chantiers de l’Atlantique, shipowners and third-party architects and designers.

Once a basic layout has been agreed, specialists from the design and engineering teams create each cabin in precise detail, including basic room design, bathroom layout and electrical cabling, as well as design elements such as lighting, bespoke woodwork and unique furnishings. The entire process is completed in Solid Edge, from the first conceptual phase to the second, more detailed design phase.

“Working in Solid Edge lets us go from a general design phase to a much more detailed phase without losing information,” says Gwenael Enet, cabins design department manager, Chantiers de l’Atlantique. “Solid Edge allows us to improve the quality of our cabin design models. We can communicate better – not only with the different designers and architects on the customer side – but also with our suppliers and colleagues in production who have to integrate our cabin designs into SmartMarine.”

Cabins are constructed on a dedicated assembly line in the shipyard, where they construct between 25 and 30 cabins per day. Each prefabricated layout is ready to be placed into the cruise ship under construction, saving time and boosting the overall quality of the integration process.

Integration skill

“We handle an enormous number of objects and need a tool that can interface between hundreds of different jobs,” says Marie-Gabrielle Gossiaux, technical manager of hull integration. “So it is extremely important to have a unique digital twin that every person can consult easily based on SmartMarine. On the other hand, Solid Edge helps us develop concepts that are more mechanical, more complex.”

The advantages of Chantiers de l’Atlantique process, says Gossiaux, is that it enables designers to create concepts while interfacing with other teams and design studios working on concepts for other sections of the ship, while coordinating the entire vessel digitally throughout the company, using the SmartMarine interface.

“You have to remember that our main job is as an integrator,” says Gossiaux. “We have to be able to work together extremely well, so it is not just everyone working on their own in their own camp, so to speak.”

She continues: “The main idea is to utilise both solutions to our advantage and make a little flowchart: what do we do with SmartMarine and what do we do with Solid Edge.”

The process of creating this massive digital infrastructure is still a work-in-process, especially as the teams look to further homogenise the process, adding a more detailed standard catalogue and data structure, even as cruise ships continue to grow in scale and complexity.

And as part of staying at the cutting edge of development, Chantiers de l’Atlantique is adding more environmentally friendly technology to its ships, developing its own fuel cell technology and launching its first vessels with sail propulsion by 2025, helping to bring the wonder of ocean travel to passengers for many years to come.