Inventor is still Autodesk’s best-selling 3D mechanical design system and each year sees a range of updates and enhancements to its already rich and mature feature set. We take a look at what’s coming in the 2019 release

Next year, Autodesk Inventor will celebrate its twentieth birthday. It’s a milestone anniversary for a product that embodies the company’s move away from building everything on top of AutoCAD, to become the wide-ranging provider we know today.

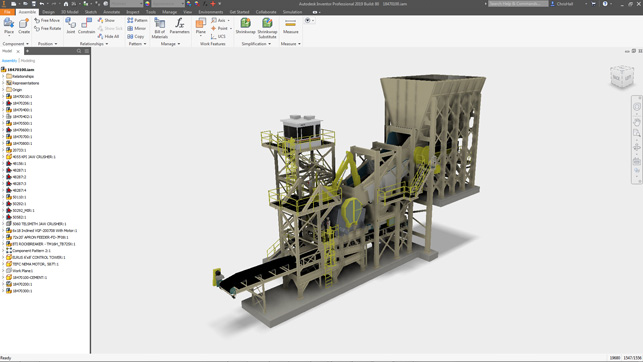

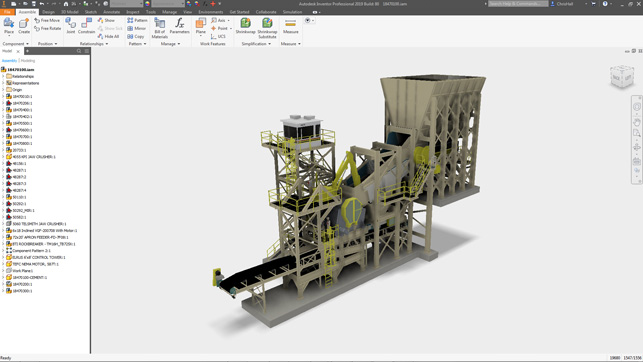

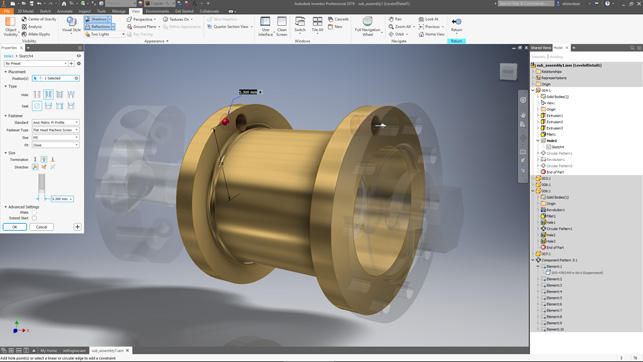

FIG. 1 Inventor’s performance under the hood has seen some work to help build larger and large assemblies

Despite the time that Autodesk has spent developing and promoting its Fusion 360 platform in recent years, the more mature Inventor still gets plenty of attention, with a solid amount of work apparent in every release and subsequent updates – not just bug fixes, but substantial new functions appear over the course of every 12-month release cycle. So what does Autodesk have in store for the Inventor 2019 release?

To kick off, there’s the usual work done to make the system more responsive under specific conditions. When it comes to mechanical engineering software, the processes that make the most exacting demands are typically large assembly design, drawing view creation and third-party data imports. Activities like these can really push the software, and your hardware, to the limit.

One way to make things more efficient is through multi-core processing. With that in mind, Autodesk has been adding multicore support to Inventor over the last few releases and this one is no exception, with that support extended to include creating and updating precise views in drawings.

There’s also been work done to make handling large assemblies more efficient, both in full mode or when using lightweight geometry representations. Of course, that may mean that users start building even more complex and demanding assemblies with even more detail – but that’s just the way it goes.

Inventor – user experience

Moving on from performance to look at some of the more practical aspects of using Inventor, there are a few key changes to the user interface. This has remained pretty much the same for some time now, and follows the ribbon guidelines used by Microsoft Windows applications, but there have been some improvements worth mentioning.

For example, the measurement command got some love in the 2018 release, but for 2019, it has been reworked entirely, to provide all features and functions in a single panel. The same is true of the hole command, another feature that was due some attention. You’ll now find everything you need to define engineering hole features in a single dialogue.

It might seem strange to focus on such basic aspects of the software, but the reality is that the way that we use computers and display devices is changing.

With higher resolution monitors, it makes sense to have all your options, functions and variables on a single panel, rather than hidden away within various tabs in a dialogue box.

On the subject of threaded holes, meanwhile, there are also some new tools to help formalise their use across an organisation, with presets that enable users to dictate how threads are defined, which are available and which are considered best practice.

Lastly on the user interface front, there are two configuration options I want to mention. First, you now have much more control over how the system looks like to colour-blind users. I was recently speaking with a friend who works as part of a four-person design group using Inventor. Since three out of four of its members have colour blindness requirements, this will be of huge benefit to them and to many others.

Second, you can now migrate all customisations made to the application in previously installed versions into the new one.

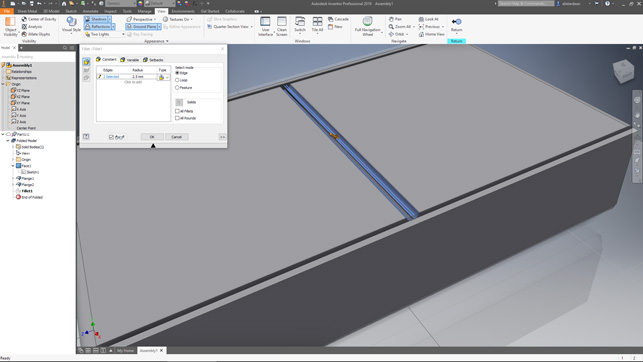

FIG. 2 Inverted fillets are a new option, perfect for adding in those weld preparation features

Inventor – modelling updates

Inventor is both broad in terms of the features it offers and deep in terms of their functionality. These are the main benefits of maturity. But again, there’s always room for improvement, as this release amply demonstrates.

On the core modelling front, it’s clear that work has been done on the helix modelling tools. Inventor has always given users a good amount of control over creating helix curves, but the tools are now more interactive and also allow you to create variable radius helices, which is ideal for modelling complex mechanical components, threads or cam forms.

Another improvement, a slightly left-field one, is the ability to define an inverted fillet. Whereas a standard fillet will remove material in order to give you by default a tangentially connected transition between two faces, with this new option, it gives you the opposite. That’s useful for all manner of activities, from woodworking to weld preparation to modelling in broaching operations.

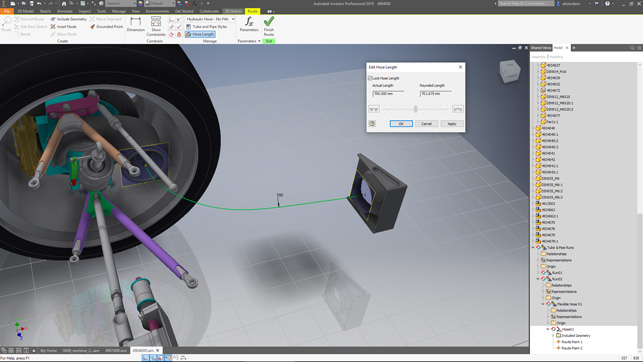

There’s an interesting addition in the Tube and Pipe extension that allows you to define a sketch entity for a tube, pipe or duct, with a specific length. It’s this kind of addition that will be useful for many users, and not only those modelling up tube and pipe work.

There are many instances, for example, where having a flexible connector between two positions, at a specific length, makes huge sense, whether to ensure components are standardised or to assess reach of parts within an assembly (for example, in exhaust work or air intakes, as per our example in Figure 3). There has also been some work done on constraints in tube and pipe design and in particular in defining constraints between existing geometry and references.

Ilogic rules

For those who haven’t already dug into it, iLogic is Autodesk’s name for rules-based design inside of Inventor. It’s been there for a while now and Autodesk reckons that around one in five users have at least experimented with iLogic.

In the last few releases, the company has made the tools easier to adopt, with a view to lowering barriers to entry when it comes to adding intelligence and automation to parts, assemblies and drawings. Examples include the ability to add more feedback when creating rules, such as autocomplete, syntax colouring and capture of a model’s current state as the starting point.

But more advanced functionality has also been included, from external rules and triggers to the ability to add and delete parts, assemblies and constraints, rather than just suppressing them.

Inventor – shared views

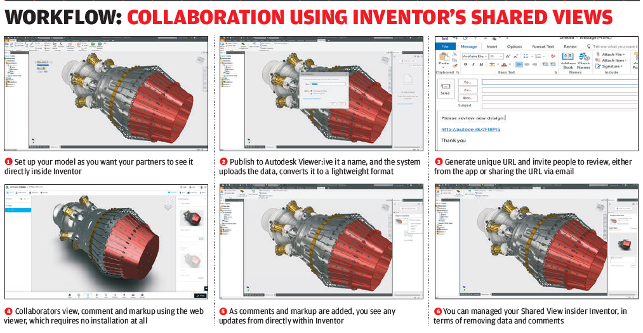

Shared Views is one of two subscription benefits included in this release of Inventor. As Autodesk tries to move more customers away from the traditional annual maintenance model to one based on subscription, it’s clear that incentives for subscription customers, in the form of bonus functionality, will start to appear in the software. In this instance, it’s all about collaboration.

In short, Shared Views allows you to upload a lightweight version of a model to Autodesk’s cloud-based model viewer (viewer.autodesk.com) and then share it with customers, suppliers, partners and such. This will allow them to view, measure, markup, section and perhaps most importantly, provide traceable feedback on that model.

While it’s true you could achieve that simply using the Viewer service on its own, doing it from inside Inventor brings feedback items directly into the Inventor interface. (That said, there’s no way at present to formalise these and document them as a key part of the development of that model).

This isn’t a heavy, closely controlled collaboration process – it’s much lighter and more informal than that. But assuming your organisation is comfortable with sharing such data on the web, in a secure environment, then it will help you conduct quick co-working sessions with others quickly and without too much hassle. Think Dropbox, but with a great level of control and commenting.

Tech preview: Fusion & Inventor

As mentioned at the start, Autodesk has both Inventor and Fusion 360 and while both address the mechanical and industrial design industries, they work from different perspectives and take different approaches.

Inventor is a traditional desktop system, Fusion 360 is cloud based. If you’re an Inventor user, chances are you already have access to Fusion 360, have tried it out and maybe even incorporated it into some of your workflows.

The issue here is that, with separation between the desktop and the cloud, moving data between the two systems can be tricky. They may share the same underlying technology base, but the reality is that when they do share data, they do it in a disappointingly non-intelligent way. For example, until recently, the only way to use Fusion data in Inventor was to export a STEP file from the former and open it up it in the latter, much as you would do when importing any other file.

This has recently been extended using Autodesk’s AnyCAD technology, which allows you to open up a third-party dataset as either a full import or as a reference model. It will maintain a link to the originating file and allow you to factor in any subsequent changes to that data.

On top of this, Inventor 2019 sees the release of a desktop connector that enables users to link cloud-resident Fusion 360 data from their desktop Inventor installations, so they can maintain that same link using AnyCAD, but directly to cloud-based data files.

If there’s a caveat here, it’s that to do this, you will need to have subscriptions to Fusion 360, Inventor and Fusion Team (the cloud-based data sharing and collaboration platform that Autodesk previously called A360). These are all included in the Product Design Suite and Collection bundles.

FIG. 3 Tube and pipe lengths can be locked to a specific dimensonal value

FIG. 4 The hole and measure commands have been reworked to provide all of your options in a single panel, which is better for today’s larger and higher resolution displays

Model-based design

Whether they call it model-based design (MBD), PMI or 3D drawings, CAD vendors are all pushing the ability to include manufacturing documentation in the form GD&T directly on your 3D models, rather than in separate 2D drawings.

While this MBD approach has certainly caught on in some industries (particularlyautomotive and aerospace), it’s still not seen much take-up elsewhere in manufacturing, despite what software vendors claim.

The reality is that defining GD&T in a two-dimensional drawing is a well-documented, well-understood and well-communicated process. By contrast, MBD is most certainly not, and this challenge is further compounded by software issues.

First, defining 3D annotations on a 3D model is a complex business and not an intuitive one in most cases.

Second, while most systems will allow you to define that information and store it natively, they do a pretty poor job of allowing you to read in similar data, even using well-established standards such as STEP AP242. In other words, far from disappearing, the 2D drawing is going nowhere for a while.

Inventor has gained MBD tools over the last few releases and the latest release takes these to a new level. For those experimenting with such workflows for the first time, one feature may be particularly useful: this is the visual feedback you get on the status of your part in relation to the tolerance advisor. Unfortunately, there’s no mechanism to read in data from non-native MBD-enabled parts, whether via STEP, JT or anything else.

In conclusion

As I stated at the outset of this review, at almost twenty years old, Inventor has so far avoided the fate of other software packages of similar vintage, which have been superseded, neglected or simply faded into irrelevance. Instead, it’s looking fresh, up-to-date and is keeping pace with new trends.

From the reworking of the user interface to improvements that have gone on under the hood, from tweaks to existing tools to the introduction of new ones, there’s plenty in this latest release for users to get their teeth into and much that, over time, they will want to incorporate into their day-to-day workflows.

| Product | Inventor 2019 |

|---|---|

| Company name | Autodesk |

| Price | £2,112 per year |