An Oxford University spin-out Qdot is developing high-performance cooling technologies to remove the heat build up in the technologies set to power the energy and transport methods of the near future and beyond.

The Qdot team is already working with Tokamak Energy, a company currently building a fusion power plant at the Milton Park scientific hub near Oxford.

Qdot’s thermal management tech might also be put to work in electric vehicles (EVs), slashing the time it takes to charge their batteries, increasing battery performance and extending battery lifespans.

More immediately, Qdot has its sights set on the electric aircraft market, focussing on heat removal from batteries, which in turn helps to manage payloads for electric craft, with current battery pack technology unable to meet the demands placed on it.

Through Qdot’s thermal management technology, there’s potential to drastically increasing power densities, without the need to alter battery cell chemistry.

This includes designing power dense battery packs, intricate additive manufactured heat exchangers, and high performance heat sinks.

While commercialisation of its technology may be some way off yet, Qdot continues to scale its operation while keeping tabs on its own resources, including the CAD technology they need to design and prototype new products.

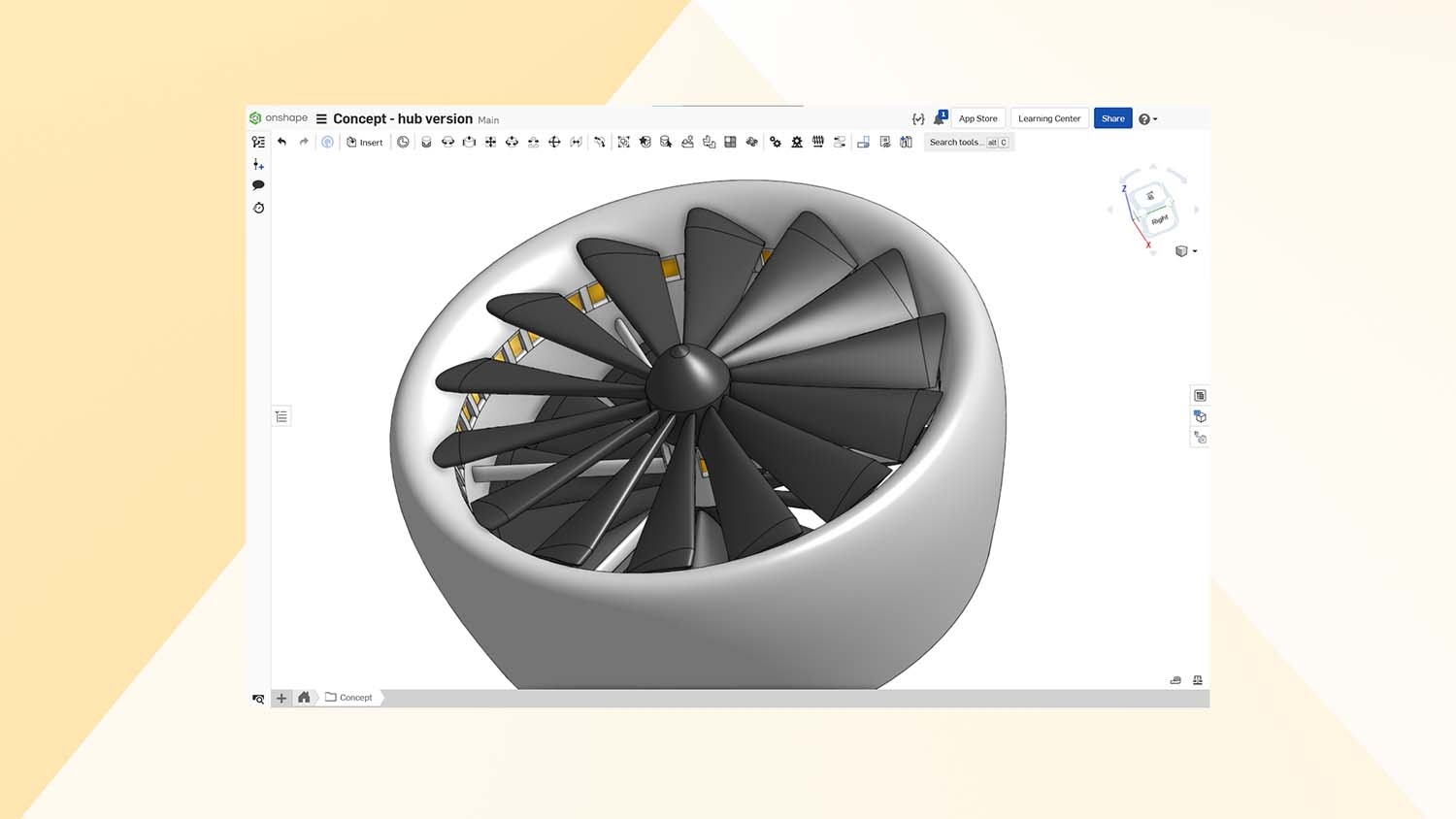

The collaborative nature of Qdot’s work put them down the path of using Onshape when designing battery cell modules. “Any of our engineers can access the latest version of the design. They can open it, manipulate it and make edits. Then they can share those changes with the team and another engineer can review changes and provide input and approvals,” says Qdot COO Dr Holt Wong. “It’s a team effort, but we don’t all have to be sitting in the same room.”

The engineering team is exploring how it can better use the Onshape version control functions. As Dr Wong observes, things get pretty complicated when multiple team members are working on multiple possible designs. Naming conventions for files can quickly fall apart if they don’t make it really clear to everyone involved what differentiates one version of a file from another.

The team has found Onshape’s product data management (PDM) capabilities enforce version control to give everybody greater clarity as to the current status of a file. The system also tracks which files are out of date and creates audit trails of edits made to them.

“That way, we’ll get a clearer view of which parts were changed, which parts were put out to quote, which have been actually manufactured,” says Holt. “We’ll know when a particular version has branched off in different directions and been edited. It should be a lot easier for our engineers to understand which files they should touch, which they shouldn’t, and which represent an actual product that is ready for manufacture.

“When you’re just doing concept work, working on potential designs, release management is not so important. But when you’re close to actually getting things made for you, you want to be 100% certain that what you’ve got in a particular version is exactly what you intend to have made.,” he explains.

With the aviation industry projected to account for over 22% of all transport CO2 emissions by 2050, the race is now on to balance sector growth and climate targets. The electrification of flight has a vital role to play here, so the sooner it can get its thermal management technology onto the runway, the sooner Qdot can taxi for take-off.