Inspired by cafe racers and electric violins, the Arc Vector promises a truly unique experience for motorcycle enthusiasts looking for a high-end, all-electric ride. DEVELOP3D went behind the scenes to hear about the motorcycle’s design from Arc Vehicles CEO Mark Truman

It takes a very special motorbike to impress former British Superbike Championship runnerup and MotoGP rider James Ellison. In the Arc Vector, it looks like he has found that bike.

Over the summer of 2022, Ellison has been working with the team at Arc Vehicles, a spin-off from automotive company Jaguar Land Rover (JLR), to finesse the final spring and damper settings on the Vector’s innovative suspension system.

He certainly enjoyed the experience. “The way the machine carves up corners is incredible. Vector is definitely big on ‘grin factor’,” he says. “It’s just so different to anything else you will ride. I’ve been really surprised by the agility. The bike changes direction like a much smaller bike due to the steep steering angle it can run. This means the bike can be flicked from side to side with little effort.”

That glowing praise is all the more striking when you consider that the Arc Vector is the world’s first fully electric neo-cafe racer. And the team that designed it, led by Arc CEO Mark Truman, is no less infatuated with their creation.

Truman, a self-confessed motorcycle fanatic, regularly takes the bike out himself and jumped at the chance to ride alongside Ellison, to hone the final settings before the Vector goes into production. “Riding the Vector alongside James has been fantastic,” he says. “His perception and feeling for the slightest change to the settings are second to none and his experience goes without saying.”

Cafe racers and electric violins

Arc Vehicles was spun out of JLR in 2017. Truman, who previously led JLR’s White Space innovation team, developed an electric motorbike prototype during his time there. Management were so excited by the idea, that they happily gave their backing to the spin-out and to Truman’s ambition to build a market leader in electric recreational vehicles.

What Truman and his team also have is the freedom to work from first principles. “We’re very lucky in that our products are more at the premium end of the market, so that means we are able to deliver a vehicle from scratch each time and develop innovative products that really break the mould, rather than working from carry-over content from previous vehicles to save time and costs,” he says.

“So we can go right back to basics: ‘What are the use cases here? What would be the perfect product to fit those use cases?’ From there, we try to work in a way that is as unrestrained as possible, carrying that concept right through into production so that the final product is very much a representation of the idea we had right at the start of the project.”

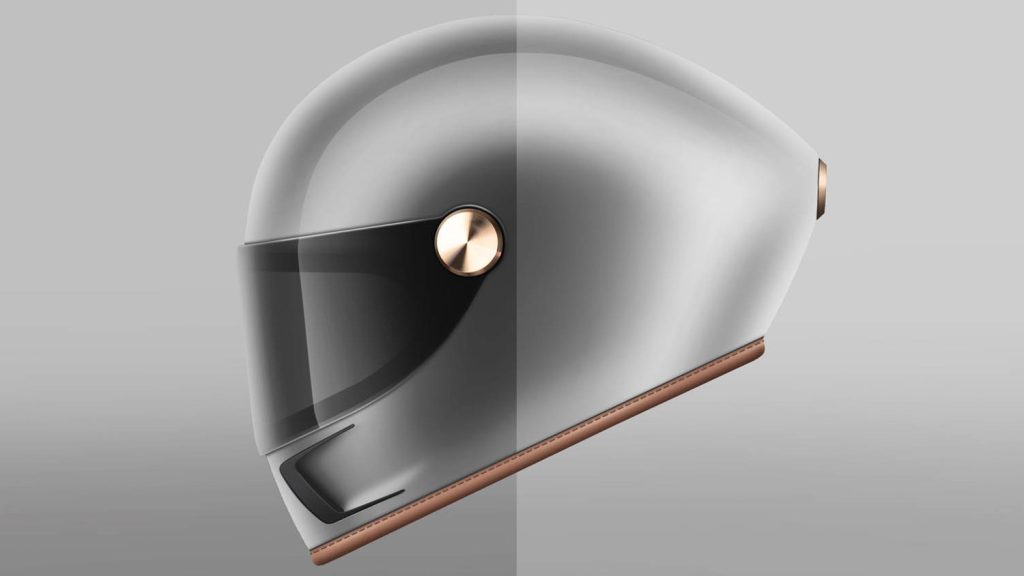

So what was that idea for the Arc Vector? The answer is two-fold. First, the team wanted to create a very futuristic motorcycle, with retro flourishes. “We were thinking in terms of how a cafe racer would look, if the term ‘cafe racer’ was first coined ten years from now,” Truman says.

Second, they were inspired by the appearance of electric violins. “We found some beautiful pictures of instruments that had everything in place that they needed to make a beautiful sound, but where anything that wasn’t required had been taken away. We thought they were stunning and that seemed a really nice philosophy for our product, as well as other products from us in the future.”

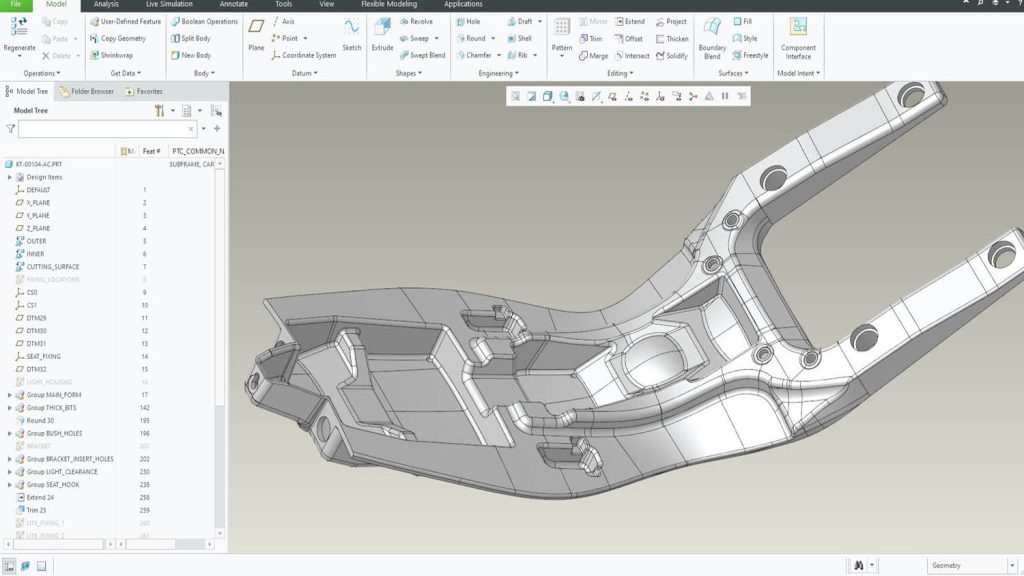

To take these eclectic concepts to a production-ready product, the initial ideation process at Arc is very manual, but quickly moves into PTC Creo for 3D CAD. Arc has used PTC Creo since Day One of its existence, supported by Cambridge-based Root Solutions, part of the worldwide PDSVision group and PTC’s longest standing Platinum Partner in the UK.

Initial ideation involves a lot of “whiteboards, blackboards, Post-it notes and mind maps”, says Truman, then 2D sketches, Illustrator, Photoshop and so on. A lot of 3D printing goes on, too, in an effort to move away from the traditional clay modelling processes typically associated with designing this kind of product. Rapid prototyping using 3D printing, Truman explains, makes it easier for designers and engineers to be working concurrently.

But work in Creo starts early, he says. “We’ll have designers working on surfacing in Creo and engineers using it to work on parts pretty early on, figuring out how parts will fix to the product, how we get that quality right, the gapping right and so on. We want to be thinking about all of that as early and as upfront as we possibly can.”

He and his team wanted to avoid a situation where designers create something and then throw it over the fence to engineers, who then have to try to make it work.

“That often results in a very argumentative process. The designer gets engineering back that isn’t quite the same as what they designed. Or engineers get stuck with trying to figure out something that’s just not possible or that’s going to be too expensive to achieve.”

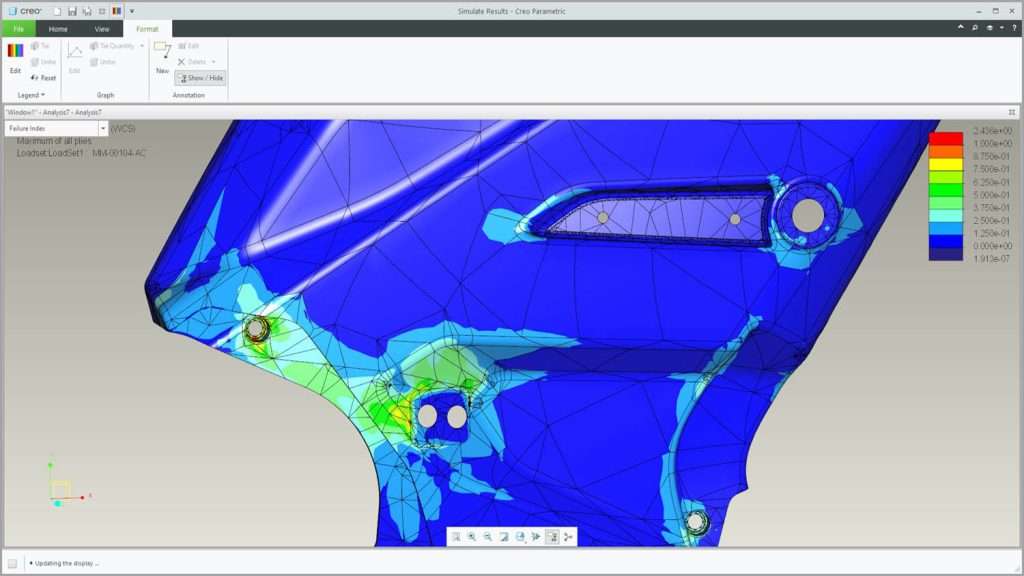

Collaboration tools in Creo support that process, helping designers and engineers to share ideas easily and keeping all relevant, up-to-date information in one software package. The team at Arc is also using Creo’s generative design and design for additive manufacturing (DfAM) capabilities more and more, he says. They’ve given the team the ability to think more creatively and to assess manufacturing methods based on different attributes such as cost or weight, he says.

“We do a lot of reverse engineering on our early prototypes, to decide how we could create individual parts better. When you first set out, you’re probably not as concerned about costs, but when you start getting to the end of the process, you can really start to understand how much things might cost and then make changes,” he explains.

“So at that point, there’s a lot of scanning that goes on of those initial parts and then reverse-engineering the CAD that we’ve created, with reference to generative design, which informs us of improvements we might make. It’s fantastic to have that ability to revisit and refine with a high degree of accuracy.”

Since around 50% of the manufacture of the Arc Vector is outsourced to specialists, these collaborative features are also a help in working with suppliers. “Obviously we don’t really share the full bike with anybody in the outside world, but Creo helps us to share relevant 3D CAD information and drawings with the companies we work with.

Arc Vector // Accelerating innovation

All this has led to a final design that can boast some truly innovative features. The Arc Vector utilises a carbon front-swing arm and hub centre steering, resulting in a bike that feels similar to one that uses front forks, but offers increased stiffness and the ability to run on steeper steering angles. With hub centre steering, for example, the Vector runs a 20-degree rake angle.

The company is also looking to get great feedback from 10 customers who will participate in a programme to help develop the Arc’s human-machine interface (HMI) system. Each participant will receive an Angel Edition (AE) Vector motorcycle and engage with a testing programme to try out prototype versions of the HMI system on tracks in the UK and US. Their direct feedback will be incorporated into the system until it is ready for the open road. According to Truman, it’s not just the “ultimate peek behind the curtain” for participants, but also a way to create a system that will boost enjoyment and safety of the product for future owners.

And since this is a premium product, those owners are given extensive opportunities to customise their Vector, resulting in a vehicle that is truly bespoke. Invited to Arc’s commissioning suite at its Coventry headquarters, they can choose between a wide range of finishes and extra features.

On top of this, an augmented reality (AR) experience will enable them to ‘see’ their Vector, parked in their own garage or on their front drive, both before and after those bespoke touches are added. This AR application was developed for Arc by Root Solutions.

“We are putting all our best creative thinking into ensuring that buying, owning and riding an Arc Vector will be a truly unique experience for owners — something very special indeed,” Truman promises.