Welcome to the second day at packed SolidWorks World 2016 – where following a day of coquettish teasing, we’re expecting a day packed out with new stuff.

We’ve an interview with CEO Gian Paolo Bassi later today, plus a wealth of cool presentations from the general sessions.

Follow todays proceedings live as they happen below the line:

Suchit Jain, Vice President on stage thanking sponsor partners & @SOLIDWORKS community at the #SWW16 @suchitjain pic.twitter.com/rMJX02nw38

— Dassault Systèmes (@Dassault3DS) February 2, 2016

8.30 – Another day, another throng of several thousand SolidWorks fanatics thrown into a giant hall. As ever with these things, everyone appears a little more dishevelled following some recreational beverages the night before. Sachet Jain is on stage to start us up with some plaudits for the 111 sponsors of the event.

MySolidWorks is first on the list as Jain enthuses about the Community – 1 million users accessed it last year for its tutorials and exam qualification training.

Also a big deal is the SolidWorks User Groups – Richard Doyle the head of SWUGN is on stage, and the hundreds of members are going wild in the aisles. None more than Todd and Jane, a couple that got married at a previous event… er…

The Seattle SWUG has been going for two decades. These communities are crazy popular in the US, and thankfully for UK users there’s a few groups out there.

The group of the year receives an award – New Mexico, in case you’re wondering

20 year anniversary for the group I now run, @SASPUG ! @ericbeatty43 representing. #SWW16

— Jeff Mirisola (@JeffMirisola) February 2, 2016

It’s hard to explain just how much the SolidWorks community means at this event, and equally shows why it’s so popular.

8.50 – Jain is back on stage to announce a new tool to help enable product personalisation – SolidWorks Make – to let retailers to take their existing 3D data and put it online for customers to tweak and buy.

#SWW16 Solidworks Make – customise and personalise pic.twitter.com/Bhvz3nCZsh

— Duncan Gillis (@gilson_design) February 2, 2016

Seemingly we’re talking mostly about products that are 3D printed, yet the CEO of Clearvision (an opticians service) that has been using SolidWorks Make to allow customers to personalisation of their glasses.

https://youtube.com/watch?v=Y135p3j-BYE

9.00 – David Pogue, founder of Yahoo Tech, is the morning’s big guest speaker – he’s on the telly over here and everything. He’s a journalist and tech-explainer-for-the-layman.

He’s going to be interviewing some new tech people on stage.

First up is the Japanese Space Elevator Association. They’re trying to create a 100,000km tall elevator up into space to help bypass the problem of gravity.

They’re a bit nuts – and they need carbon nano-tube technology to get a shift on and develop to actually build one.

To begin with they’re taking a mile long rope tether into the air with weather balloons, and testing its Spider climber to race up to the top – with 20 university teams entering their climbers to carry a weighted load up the tether.

Sometimes this can go wrong…

9.15 – Jain is back on stage to talk about SolidWorks’ education projects with Marie Planchard who heads up the education portfolio. She’s a very enthusiastic lady – and that enthusiasm comes to a peak when talking about the university teams that are here from the SolidWorks supported Formula Student teams, and some special guests from Lithuania.

Taking certification exams is a big deal, with 146 new certified users already qualifying at this year’s onsite SW World event.

9.23 – There’s tools on the way for the younger generations too – SolidWorks Apps for kids – that will be available on all mobile devices. You can test the beta here.

9.27 – It’s time to look at the world of start-ups, with David Pogue introducing Brewbot to the stage – a robot that brews beer.

The idea is to use the IoT to check in on your brewing beer – taking the time down to four hours. “It’s a connected brewery”. Brewbot Core is the embedded brain that communicates with both an app (that has recipes – select your pick and Brewbot send you all the ingredients pre measured) and an array of sensors inside the machine where you chuck in the hops, water and other natural goodness.

The tech means they can get the production cost down to 75 cents a pint – a big drop in price from the standard $2- to $3.

The machine costs you $10,000… You’ll need something a bit stronger if you stump up that much… Turns out they’re based in Belfast?!

9.40 – We’re back to certified engineers, with CEO of Tethys Engineering, Frederic Ramouille explaining how his fears for the number of future of engineers made him start a database where student engineers can display how much certification and experience they have within a commercial software environment for students. Companies can find qualified teams easy, engineers out of university can get valuable experience.

It’s clearly getting a lot of interest from the people in the room as the wifi signal has been down for five minutes now… and when it comes back up the Tethys website has crashed.

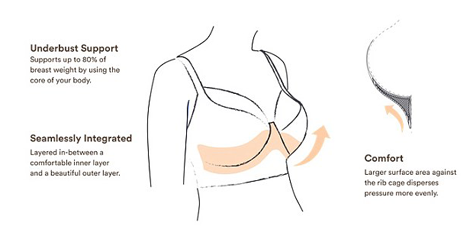

9.52 – Trusst Lingerie is on stage, a company for women that have large breasts and the weight problems they create.

The designs create a truss under the boob around the ribcage that takes 80 per cent of the strain off the shoulder straps – and it was developed in an engineering fashion (rather than a fashion fashion) in SolidWorks.

Using #CAD to design lingerie! #SWW16 pic.twitter.com/yzjv9hj2Yt

— SOLIDWORKS (@SOLIDWORKS) February 2, 2016

Press only session

10.50 – We’re back with today’s customer speakers as they field some press questions.

First up is Brewbot and its ‘digital distribution of beer’. “It’s kind go like a MakerBot but for beer – you can download someone else’s ‘design’ and make it wherever you want.”

There’s a lot of talk about beer recipes, hops suppliers and the craft beer mantra… not a lot of design happening…

There’s some vessels, and the app walks the user through the entire process – when to do certain actions, with some sensors inbuilt to aid the process.

The design issues come with automation aspect, before adding in the user experience to make it worth that ten grand. Each batch is roughly 25 litres, although you can knock out 40 litres at a push – not a bad little earner for 2-3 weeks of brewing.

11.20 – The Japanese Space Elevator Association are in front of the media room and there’s questions itching to be asked. Cable development and materials science is the flavour of the first questions.

Currently the problems are at a molecular level – rather a big stumbling block for getting mankind up past the atmosphere. Currently the cable breaking length is currently in excess of 1,000km (untested at this point) but still a long way short.

It’s not a greatly funded project, but the idea is to bring more attention to the technology against the huge established industry of making big rockets.

However, while lots of funding gets pumped into materials development elsewhere, these guys are pushing to develop more simulation models etc. while the wait goes on for materials.

The concept of a space elevator was first published in 1895 by Konstantin Tsiolkovsky, with a free-standing tower reaching from the surface of Earth to the height of geostationary orbit.

11.50 – Trusst Lingerie – solving the problem of bigger busts and the problems traditional bras cause – are now further explaining its products and the backstory. Its bra has a much wider weight distribution.

The design was prototyped with multiple 3D printed iterations – another benefit of designing in 3D CAD rather than traditional 2D pattern cutting – with the final parts being injection moulded.

A big part of the development came as a result of the resources and mentoring from AlphaLab Gear – a start-up incubator in Pennsylvania that the company was developed through – and availability of a TechShop for prototyping.