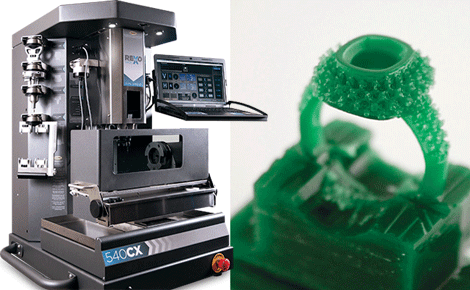

The GemVision Revo540CX can produce super high detail wax parts for lost-wax casting in the jewellery industry

In a week where we’ve been chatting a lot in the office about 3D printing metals we became aware that it’s still a niche business, and that lost-wax casting is still king for small, detailed, metal parts.

This is not to say that lost-wax casting (or investment casting) technology hasn’t advanced, with wax 3D printing and advanced CNC milling being a revolution in its processes, it is speeding up industries like jewellery design considerably, while offering more freedoms for shapes not allowed by traditional moulding methods.

There’s a lot of choice out there offering a range of different finishes for your price point, and as it’s all based on a process that’s been used for thousands of years, which has to be reassuring, no?

Lost-wax casting 101

The traditional process begins with a wax model is obtained either from injection into a silicone mould (needing a solid master model and a lengthy moulding process) or by being custom-made by carving a block of wax, which as this video demonstrates, is a skilled and intricate process.

This wax model is then given sprues (rods to let the, eventually burned out, wax escape) and fused onto a stem rising up from a rubber base.

A metal flask (a bit of steel pipe) fits over the lot of it, with the rubber base holding the wax parts suspended in the middle, before a refractory plaster is poured into the flask, filling it.

The plaster hardens, the wax is then burned out in a kiln, and the metal is poured into the space left behind, either by centrifugal or vacuum casting.

As with most things, it’s the creative side that’s the hardest part, and carving an intricate wax ‘master’ by hand can take an age, and leaves you with only a single model should anything go wrong in the kiln later on.

The 3D printing approach

This image shows a casting tree with designs straight from an Envisiontec 3D printer before and after the investment process

The biggest difference between traditional methods and using 3D printing is that there’s no need for a physical ‘master’ model to be carved out of wax. Instead the ‘master’ is your CAD file, and the 3D printer simply prints out the wax model using a synthetic wax using stereolithography (SLA), and because it’s a CAD model, you can print out as many as you want, or tweak the design far easier.

Additionally, more fiddly bits can be removed from the process, with 3D printing allowing you to print your model straight onto a sprue, and while you’re at it, connect on a bundle of other parts to save casting time later on.

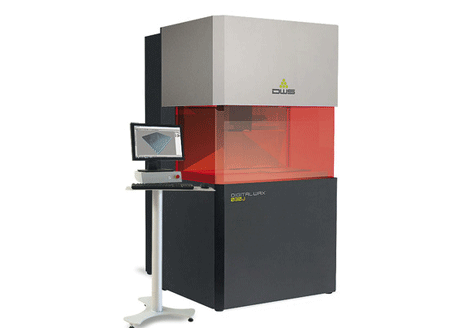

The 3D printing element is a pretty standard SLA process, as shown by this video from DWS, an italian 3D printer manufacturer that specialises in the jewellery industry.

//www.youtube.com/embed/gV57MDNmfdc?t=1m46s

There’s a wide range of companies that produce 3D printers for printing wax, some are major 3D printing vendors that you’ll already recognise, while others are more specialist.

Desktop options

The ProJet 1200 prints is an attractive desktop option

All the major brands have suitably small machines for what can often be a single-person enterprise or even hobby, although prices vary so it’s wise to choose a machine that fits your requirements.

– DWS offers the dainty DigitalWax 008J, with a 65 x 65 x 90 mm build area and all its machines have a choice of six waxes for varying finishes.

– Solidscape, now owned by Stratasys, has long been recognised in the jewellery industry, and has the new Max2 machine, with a 152 x 152 x 102mm build area and automatic calibration.

– The ProJet 1200 is 3D Systems’ printer targeting the smaller end of the jewellery and dentistry market, although currently it only has one material available, VisiJet FTX Green, which leaves no residue after burnout.

– Envisiontec has the 60 x 45 x 100 mm build area Pixcera. Part of it’s super hi-res Perfactory range, this is the baby of the bunch, although it still remains the ability to print in three materials.

Bigger machines

The DWS Digital Wax 030J is has a choice of six waxes

The bigger the machines are, the more varied output and costs get, and clearly this is moving into the realm of full scale manufacturing, but the principles stay the same.

– DWS remains focussed on jewellery, with its biggest unit, the DigitalWax 030J rapid manufacturing system has been specifically developed for high productivity applications, able to churn out 800 models a day.

– 3D Systems is, literally, big at this end of the scale, with its VisiJet Jewel material partly to thank. A ProJet 7000 will allow you to cram as much as you please into its 380 x 380 x 250 mm build area, with the option of a variety of other materials, although this top level machine will inevitably come with a top level price.

– Envisiontec’s Perfactory tops out at the Perfactory 4 Standard XL, a 192 x 120 x 230 mm build area, high resolution printer preferred by some big name jewellery designers for its EC500 material.

Even Bigger

In big industry lost-wax casting has long been replaced by injection moulding and even lost-foam casting, but for those needing some seriously special parts, then Voxeljet have devised a way in which its 3D printing technology can work on a grand scale.

Using its PMMA material as a synthetic wax, it can produce parts up to 1060 x 600 x 500 mm, with the PMMA softening at 73°C and burning out without residue at temperatures over 700° C.

The models, once printed, are sprayed in several coats of ceramic spray, doubling in for the steel tube and refectory plastic, and can produce some stunning objects.

The other options

3D printing is a great technology, especially if you’re wanting to produce lots of the same designs on the same print bed. Yet a somewhat less hyped alternative is available, which the professionals still prefer for small batch, high detail work.

CNC milling is a subtractive method, effectively automating the hand sculpting of a wax master, but with all the speed benefits of having a digital master that can still be played around with.

There are a number of options available as precision milling isn’t reliant on simply one industry and having complimentary resins.

Having said that, the GemVision Revo540CX (or a Revo Mill to anyone in the jewellery trade) is specialist to the jewellery trade, leaving such a precise finish on the wax that it’s the jewellers best friend.

Unlike 3D printing there’s no layering build up, meaning no stepping, which occurs regardless of the printer resolution, leaving a finish, as one jeweller described to us as “like glass”.

It’s clearly been developed as a high precision tool, running off GemVision’s Matrix CAM software, and it will come with a hefty price tag, but other milling machines are out there.

Desktop machining

If you’re thinking of something more desktop friendly, then there’s CNC springing up everywhere, from start-ups to more mainstream brands.

The Carbide Nomad 883 CNC Mill will be happy enough whizzing through wax – its third-generation spindle is driven by a high-power brushless DC motor and is capable of cutting through aluminium.

Although the wax will have to be manually flipped due to the lack of rotary fixture, this isn’t much of a problem if you fit a couple of location pins.

The Nomad is not yet on the market, and when it does it will cost around £1,500 plus shipping.

Like other start-ups such as the Pocket NC and 5AxisMaker, the warranty and support on such a products is going to be limited.

This is fine if you’re handy tinkering with these things, or even if you’re a Maker buying it to just to learn the technology, but it’s not so great if your livelihood is reliant on it working solidly.

There are some professional desktop products from Roland DG: Its latest SRM-20, a model twinned with the company’s first SLA 3D printer, relies on location pins like the Nomad. However, it’s sold at £2,799 in the UK it comes with proper warranty and support.

Proving that the machine isn’t all sensible, the Maker community can rip up their warranty to the SRM-20 immediately and go off and hack its controller system which allows for inserting an Arduino control board, giving way to all kinds of integration with other intelligent systems.

Created especially for the jewellers, the JWX-30 is a £10,000 option for the professional lost-wax caster, giving the option to produce all needed components, with the benefit of a rotating indexer.

By far the best option, and one being used by some professional jewellers, is what CAM giant Delcam has done with the Roland iModela.

Its bundle gives you the cute little iModela machine with a pimped rotary index fixture (no manual flipping), and a copy of Delcam’s ArtCAM Express software all for £1,300.

The best option for CNC milling your wax is the Roland iModela that has been pimped by CAM experts Delcam especially for cutting wax

It’s an exciting time to take a look at lost-wax casting as a means of making things, given the crossover between additive and subtractive wax working.

Researching 3D printing metals is at the front of many companies priorities, and there have been some exciting new machines arriving at low price points, but for the time being this is one of the best means of making metal parts.

Want to know how a professional modern jewellers workshop operates in the heart of London? Find out here, as we visited the Capital’s jewellery quarter, Hatton Garden.