LSRs super sharp silicone tooling made from 3D prints straight out of the Solidscape 3D printer

Solidscape has teamed up with specialist wireless product designers, LSR, to combine high precision wax 3D printing with LSR’s silicone or metal mould making process

The process – part high resolution additive, part traditional subtractive – is capable of knocking-out metal prototypes in less than two weeks, compared what typically would take five to six weeks

Printing at a resolution of 5000 dpi, the Solidscape 3D printer creates wax patterns that don’t require hand finishing, which the prototyping experts at LSR take directly to silicone tooling or to cast metal parts without the traditional laborious hand finishing needed for 3D printed prototype parts.

Traditionally Solidscape machines are found in the jewellery and dental industry for this reason – where fiddly small parts require as little hand finishing as possible, and proprietary waxes get the part as close to the original design as possible.

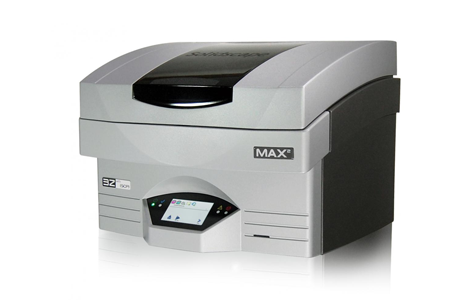

Yet with the larger build areas of the Max2 machine, bigger parts for physical electronic devices prototyping, including casings and fixtures, can be produced

“We compressed our product development process considerably on a recent program. We’ve gone from weeks of machining time and $4,000 per set of metal parts, to under two days and $200. This was earth shaking for us as well our customer,” said Jim Hollister, 3D Lab Manager at LSR.

Having spoken with Jim at the 2014 Euromold exhibition, we can confirm his excitement for the process, which with its accurate detailing and ability to use ‘real world’ materials for more accurate prototypes.

LSR Design Studio from LSR on Vimeo.

The Solidscape Max2 3D printer, with its bigger build area is making it possible for high detail electronics and casings castings