The Dakar Rally is one of the toughest races in the world, for both drivers and their vehicles. Prodrive uses 3D scanning to improve its chances in races and maintain its winning streak when it comes to putting drivers on the podium

The annual Dakar Rally, one of the most famous races in the world, covers over 8,000 km of deserts, mountains and savannahs and tests participants and their vehicles to their limits.

In January 2024, only 239 out of 340 vehicles finished the race, with incredibly tough terrain and weather conditions cementing the Dakar Rally’s reputation as a one-of-a-kind endurance event.

What was originally a race from Paris, France to Dakar, Senegal, has been relocated several times and took place this year in the desert of Saudia Arabia, beginning in Al- Ula and finishing on the shores of the Red Sea.

Prodrive is no stranger to the challenges posed by this race. Headquartered in Banbury, UK, the company is a British brand with an exceptional pedigree, having tuned cars for a variety of race teams, including Subaru, BMW and Porsche, since 1984.

It first entered the Dakar Rally in 2020. In 2024, it unleashed the Prodrive Hunter, its first all-terrain hypercar, which secured the top three positions on the podium and retails at a cool £1.25 million.

On mountainous terrain, Prodrive’s priority is making sure that cars aren’t destroyed and that drivers remain safe. In an effort to improve its cars each year, the company has employed the help of The 3D Measurement Company’s (T3DMC) Trackscan-Sharp.

Structural integrity

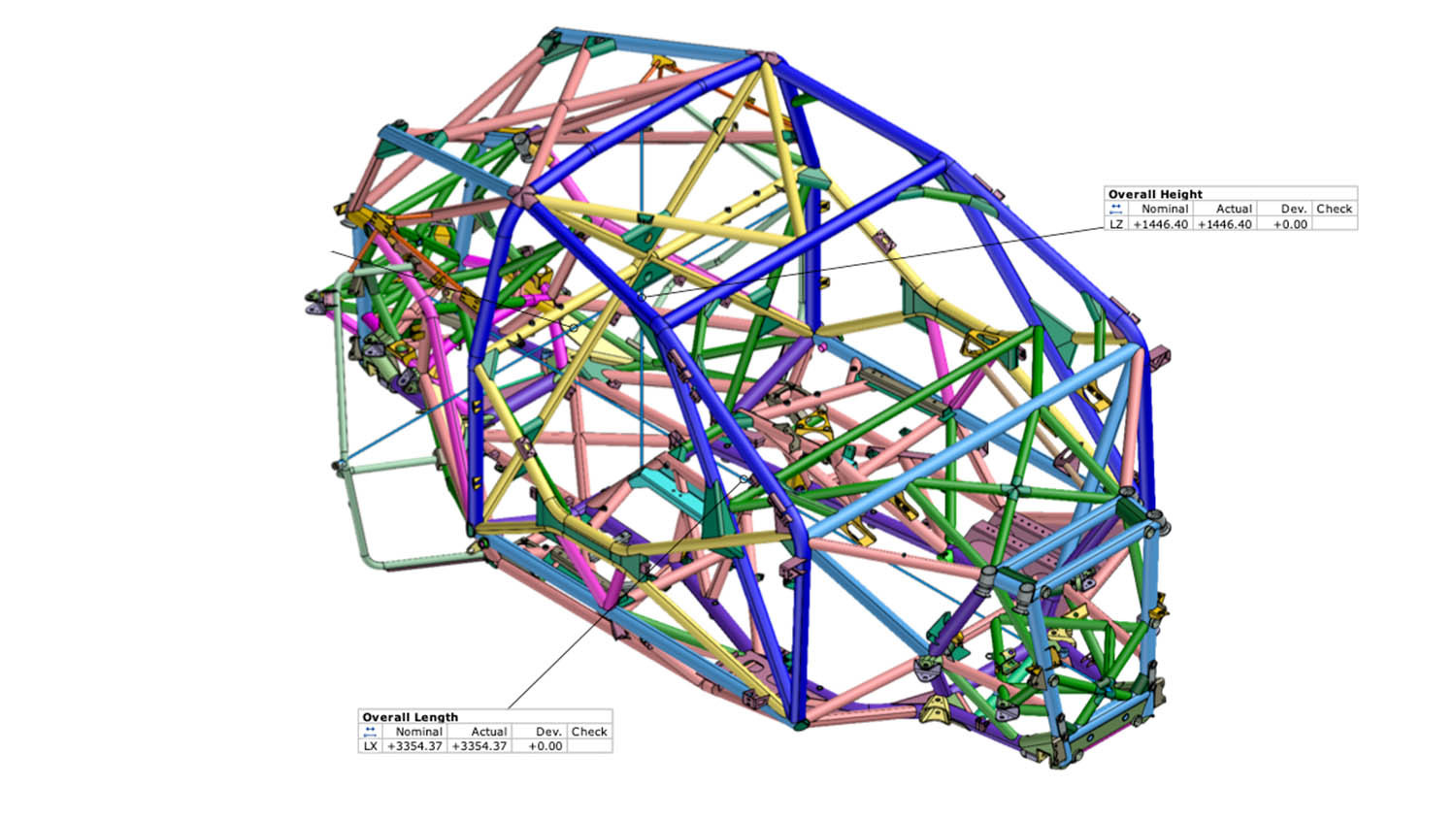

The structural integrity of a vehicle is extremely important in the difficult racing conditions presented by the Dakar Rally, and is often the determining factor when it comes to whether or not a team will finish. Prodrive conducts post-rally 3D scans of its cars to collect data about how the vehicles have coped with the conditions.

The Trackscan is a handheld 3D scanning system which has a tracking distance of up to 8 metres. It uses optical tracking technology and high-resolution cameras to create accurate, fast scans of large-scale objects. In other words, it’s ideal for cars. A 49 metres cubed measurement volume allows for a complete surface scan of the car’s shell frame without needing to reposition the tracking system. With dot-free 3D scanning and an accuracy up to 0.025 mm, seven parallel blue laser lines and 25-megapixel cameras capture every small detail, with the data processed onboard the device.

After the scanning process, the resulting STL file is imported into inspection software for side-by-side comparison with CAD models of the car’s frame. The results of this inspection are used when designing future models, to ensure durability and high performance.

Regular scans of cars mean that potential issues can be identified early on, extending a vehicle’s lifespan and reducing the possibility of malfunctions during the race. Post-rally inspections provide information about how the vehicle withstands the harsh conditions of the Saudi Arabian desert.

“The terrain would smash any normal car to bits. What we need to do is monitor the health of our vehicles, in particular the space frame,” says Prodrive vehicle director, Paul Doe.

Prodrive also uses the Simscan, also from T3DMC, as a smaller, portable scanner, which allows for single-handed operation and more detailed scanning, with accuracy up to 0.020 mm and 2.8 million measurements per second. It offers dual measurement volume for scanning both large and small areas.

“With both of these items in our armoury, we’re able to do things at such a higher level and very fast,” says Doe.

Looking ahead to the 2025 Dakar Rally, Prodrive has announced a partnership with Dacia to compete in the World Rally-Raid Championship, which culminates in the Dakar.

With the help of 3D scanning, Prodrive and Dacia have the potential as a partnership to create cars that revolutionise the Dakar Rally, and have three teams lined up for Dakar 2025, pushing the limits of what’s possible in the world’s toughest race.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here