Artec 3D has launched its 3D scanning software, Artec Studio 16, including its collaborative Cloud platform to help users access, view, comment on, and process 3D scan data online.

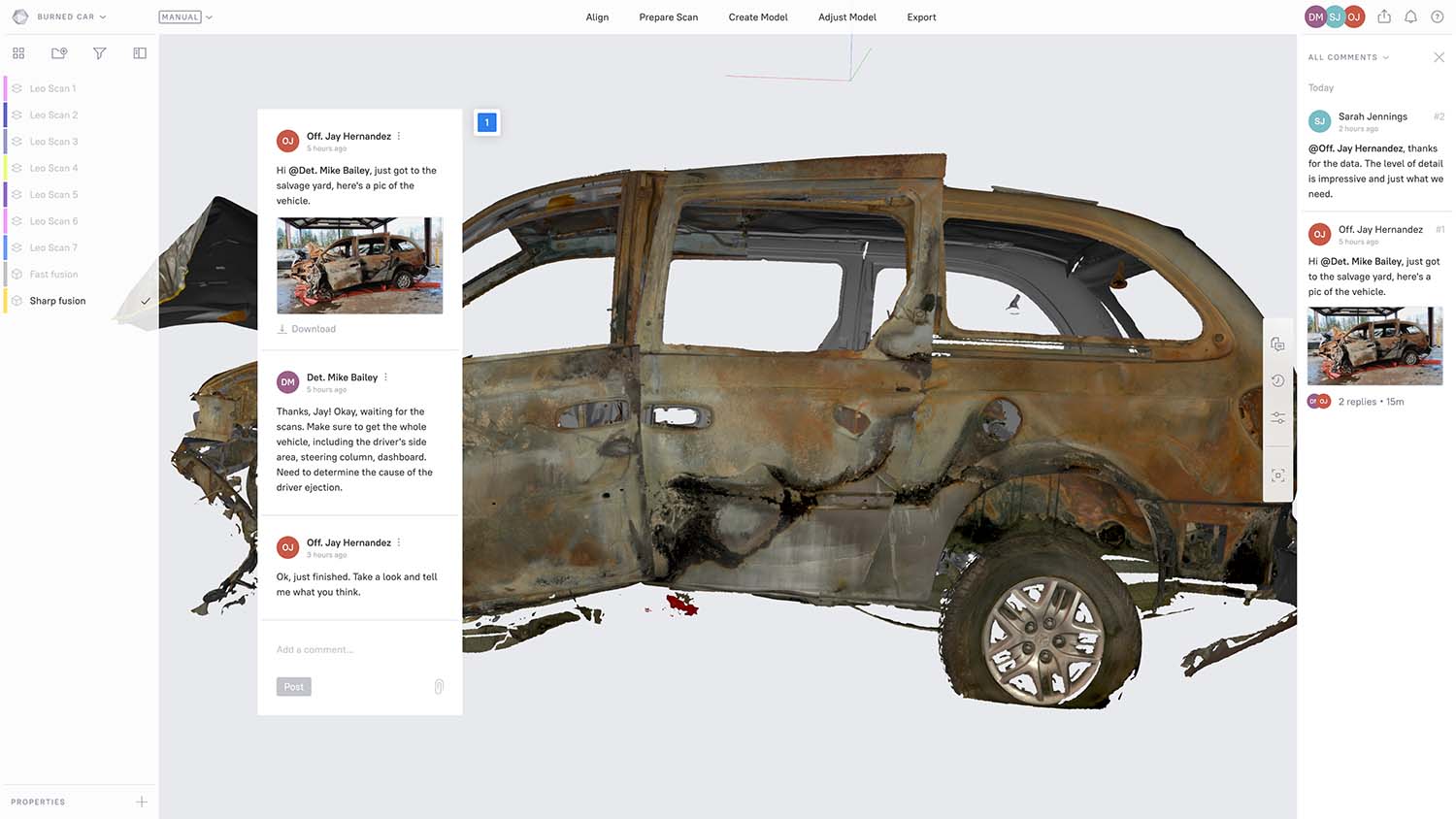

The move to integrate Artec Cloud with Artec Studio 16 is to streamline 3D project management, letting users upload and share 3D data with peers, leave comments, send photos, and have full conversations.

With Artec Cloud, users can also process 3D scans in their browser from any location and from any computer, without being constrained by the technical limitations of their devices.

“Thanks to our major software releases, every year our professional 3D scanners are becoming faster and more powerful and therefore are capturing more data than ever,” said Artec 3D CEO Artyom Yukhin.

“Our development of industry-leading software solutions and AI-powered algorithms is critical for enabling the 3D scanning industry to reach new heights. The release of Artec Studio 16 and Artec Cloud equips users with unprecedented collaboration opportunities, flexible workflows, faster 3D data processing, and numerous feature-rich tools to meet any need.”

Upgrades within Artec Studio 16 include faster Scan-to-CAD times – in some instances with up-to 8-times faster alignment – aiding an uninterrupted scan-to-inspection workflow allows users to finish a scan, inspect a mesh, or run inspection in CX from Artec Studio.

Batch CX inspections are now possible, and distance mapping measurement calculations on complex CAD models can generated 70 per cent faster.

When working with primitives, users can now force constraints to further optimise quality inspection results. Artec says that precise point-to-plane measurement of perpendicular distances can be conducted with a few clicks, making it easy to calculate precise thicknesses or define external dimensions.

Tailored freeform primitives enable users to create custom-fitting primitives for curvilinear surfaces. Constraints ensure that primitives fit to the scan will snap into place and be ready for export – which can be done directly to Solidworks without the need for a plug-in.

Artec Studio 16 also features ‘CAD-perfect sections’ from constructed planes, and a new torus primitive has been added for reverse engineering ring-shaped objects.

Artec 3D’s neural network-based HD Mode for Eva and Leo handheld 3D scanners has been enhanced in Artec Studio 16. HD projects can reportedly be reconstructed nearly twice as fast, and the size of HD projects are nearly 20 per cent smaller.

Scan data can also be stored and processed at a later time, or on a stronger computer, if needed. New encrypted file formats let users export and store high-def data from Leo onto an SD card.

Photos taken with a professional camera or even from a mobile phone can now be uploaded into Artec Studio, to allow users to build and map texture onto the mesh captured with an Artec Leo, Eva, or Spider.

The alignment by scale algorithm allows users to match the arbitrary scale of a model created with photogrammetry to the real scale of a model captured with an Artec 3D scanner by checking a box and aligning three points.

A final key update from Artec is that Projects load “at least 10-time faster” in Artec Studio 16, bringing down the ‘loading average’ for a project to 10 seconds, while users also no longer need to wait for scans to be fully loaded before working with the data.

Project progress is kept safe with automatic saving, and a Smart RAM optimiser automatically loads essential data and unloads data that isn’t being used, creating a faster, smoother workflow.