Xact Metal and PanOptimization have partnered with the goal of expanding access to affordable metal 3D printing for small to medium sized companies.

By employing PanOptimization’s PanX software, Xact Metal was able to lower the price of additive manufacturing metal powder-bed fusion systems.

Xact Metal’s initiative is to reframe additive manufacturing technology as a cost-effective option for parts manufacturing.

It launched ‘Breaking the Mold: The Xact Solution to Better Tooling’ in April 2024, aiming to change the approach to metal 3D printing.

Xact Metal printers generate profit with less investment than traditional metal options.

“We have used PanX to help us improve the performance of our systems, understand the behaviour of the metals that we work with, and optimise the parts that we are printing to achieve the geometric performance that we require,” said Xact Metal CEO Juan Mario Gomez.

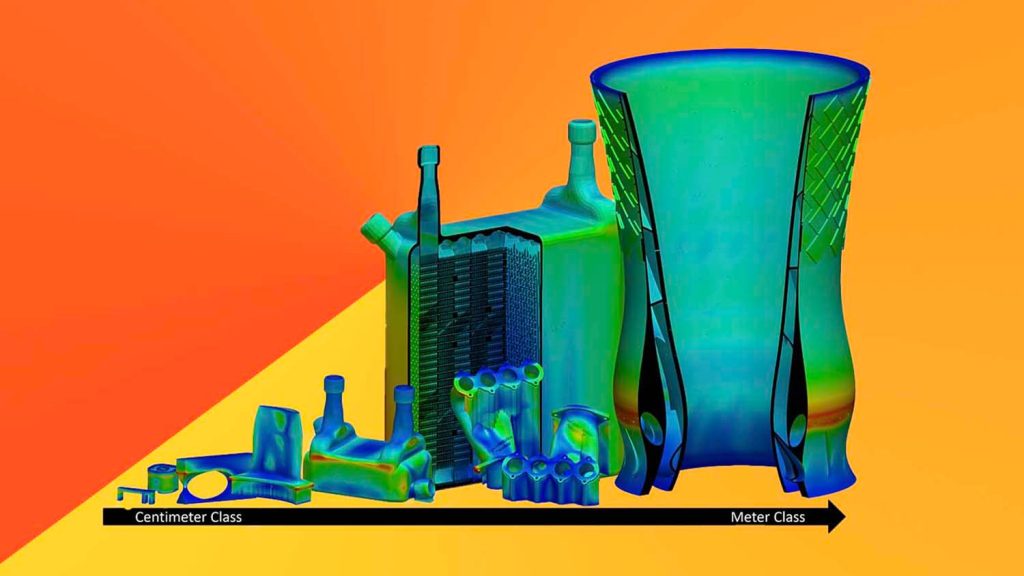

The software features a multi-grid modelling approach for thermomechanical simulation which achieves over 100 times faster run times than traditional finite element analysis models, while requiring minimal hardware.

It identifies and corrects most thermal and mechanical build issues including distortion, recoater jams and cracking, reducing the need for experimental trial and error.

“We’re excited to begin our partnership with Xact Metal,” said PanOptimization CEO Pan Michaleris. “It is a logical next step in our strategy to integrate our PanX software product line with all major machine OEMs, and an opportunity for us to go beyond our aerospace and defence user-base and expand into the broader industry of affordable metal additive manufacturing.”