Bigjigs product designer David Walling typically starts his design process with pen and paper

Parents give over their lives to their kids. Soon after they’re born, it seems, they give over space throughout their homes, too, in order to accommodate the toys that keep their offspring occupied and give them a few precious minutes of peace in the day.

I currently can’t see the carpet for train track in my own living room. The initial hand-medown wooden toy railway set, given by a friend, initially consisted of just a few engines, carriages and track. In the past three years, it has expanded. Now, bridges, tunnels, turntables, track splitters, stations and additional scenery provide endless hours of imaginative play for my son.

Although Bigjigs Toys wasn’t the first company to popularise the wooden railway set (that happened back in 1957, thanks to the Swedish brand BRIO), its own set is one of its best-selling products. Its aim for its railway, together with the other 1,200 wooden toys in the range, is for toys to be cherished, played with excessively and then passed down to friends and family, surviving all the knocks, scrapes and the odd chew that life throws their way.

But do traditional wooden toys have a place in our technology-driven world? Bigjigs Toys don’t typically come with any bells or whistles. They aren’t smartphone controlled or IoT-enabled. But Bigjigs believes its toys stand apart, because while they may be more simple than more techie toys, they’re built on the principles of helping to spark children’s imagination and propensity to learn through play. “We aim to create toys that allow children to grow and develop through exploration and fun. We try to ensure each toy has some educational value,” explains David Walling, product designer at Bigjigs.

Wooden toys also appeal to those consumers who are becoming more aware of the negative consequences of our throwaway culture, with cheap plastic toys being one of their chief bugbears. Bigjigs has recently noticed an increase in parents enquiring about the company’s responsibly sourced materials.

“A large majority of products, especially our rail items, are made from rubberwood, a hard wood that is a byproduct of the latex production process. Rather than the wood being discarded at the end of its useful life, it is harvested from replenishable forests and used in our toy production. Our managing director, Liz Ireland, travels abroad multiple times a year to personally check the quality and production at the factories,” says Walling.

The company’s focus on eco-friendly materials extends to other products in its range, which it distributes on behalf of other brands on an exclusive basis. Green Toys, for example, is a California-based company that uses recycled plastic milk bottles in the manufacture of its toys, which include vehicles, planes and tea sets. To date, Green Toys claims to have repurposed over 56 million milk bottles.

One of the lead characters of Bigjigs’ new Dino Island playset, due for launch in September

Bigjigs – on a mission

Bigjigs’ mission of making traditional wooden toys that encourage imaginative and educational play hasn’t changed since the start and, like many a successful company, its origins can be traced back to a garden shed. The shed in question was owned by married couple, Liz and Peter Ireland, who were both teachers back in 1984.

Peter Ireland has always had an interest in woodwork, having learnt a lot from his father growing up. He started making string puppets such as walking ducks for family and friends. These were straightforward to make, because he could handcraft and cut them from wood without needing machinery such as plastic moulding machines or metal lathes. Following a favourable reception for his toys, he extended the range to include giant wooden jigsaw puzzles (hence the company name Bigjigs), which the couple sold at craft fairs, markets and agricultural shows.

Realising that they could turn Peter’s hobby into a business, the couple quit their teaching jobs and launched their company from the garden shed. However, it didn’t take long before they needed bigger production facilities.

The early years of any business are challenging, especially when the founders have a young family, work long hours and have a mortgage to pay. But Liz and Peter Ireland stuck with it and 33 years later, it’s a very successful company.

Today, Bigjigs still exhibits its products to potential customers, but instead of local markets, they’re showcased at international toy fairs. The shed has been exchanged for a 40,000 square foot warehousing facility in Folkestone, Kent, from where the toys are distributed to 93 countries around the world. Manufacturing is outsourced to a variety of eastern European and Far East factories. The two-person team has expanded to 39 members of staff, including the couple’s two sons: Sam Ireland, who is now operations director, and Tom Ireland, the company’s OEM and international sales director.

Bigjigs – encourage learning through play

Although Peter Ireland handed over the reigns of toy design to the Bigjigs’ in-house creative team quite a few years ago, the family is still very much involved in the design and development process to ensure the company continues to create toys that encourage learning through play.

“We try to plan our development and product targets for the year. We use many methods to decide what products we want to design. Ideas come from across the company: the directors’ brief new ideas; I put forward my own suggestions; we use sales information, look at bestsellers, gaps in our current range and what’s popular in the market,” explains Walling.

“At this point, we begin to brainstorm in a team meeting to go through our ideas and select which product we want to proceed with through our design process.” As well ideas for new toys, Bigjigs will also update existing toys. An example is the new Dino Island playset, which includes a number of dinosaurs, together with a volcano, assembled from a selection of large play pieces that slot together.

“The toys we make aren’t designed to coincide with ‘fast fashion’. Our toys are durable and long-lasting, so they can be passed through generations. That being said, we’re constantly working on new ideas and expansions for our toys that are original designs or a new twist on a traditional toy,” says Walling.

“For the playsets, these were a redesign of an existing product as the original version required updating and it gave us a chance to improve and eliminate any problems within the design.”

An example of the trainsets that are still Bigjigs’ bestselling products

A multi-level volcano sits at the heart of the Dino Island playset

Start with sketching

The design process starts with pen and paper. This could be a quick sketch during a product meeting to help illustrate an idea or a more detailed drawing to help visualise a product before moving into CAD.

“If it is a particularly unusual or difficult shape, I will do a large amount of sketch work and scan it in to use with SolidWorks. I use sketching primarily for my own benefit, as a way to get ideas out of my head and onto paper, or to try and solve a design problem. I don’t use it as a presentation tool,” explains Walling.

At the forefront of Walling’s mind during this early design stage is product safety. As we all know, young children like to explore with their mouths as well as their hands, so designing the toys to comply with toy safety standards, including EN71 in the UK and ASTM in the US, is paramount.

“We use a small parts tube to determine small parts that could change the age-appropriate nature of the product. We also have to avoid any finger traps and strangulation hazards if the toy uses a long cord or string,” says Walling.

Following concept sketching, and depending on the product, the design team will move into SolidWorks. “For simpler, more illustrative products such as a flat puzzle, I will only use Adobe Illustrator,” says Walling.

However, it wasn’t that long ago that all Bigjigs’ products were designed in Illustrator. In fact, CAD was only introduced into the company two years ago. “Designing solely using Illustrator was very time-consuming, especially for a complex toy such as the Dino Island playset. SolidWorks has definitely sped up our entire design process,” he adds.

“For the playset, one of the main challenges was the structural design. As it is so large, it was at risk of being unstable and we wanted to keep the design as open as possible and create as many play points as we could. We kept it strong and durable by being smart about how the pieces slot together, and used locking tabs at selective points to anchor it to the base.”

The material is wood of course, but in this instance, it is quality plywood rather than rubberwood. “We use plywood for the majority of our playsets and we try to show this off by leaving parts as natural wood and the edges bare,” says Walling.

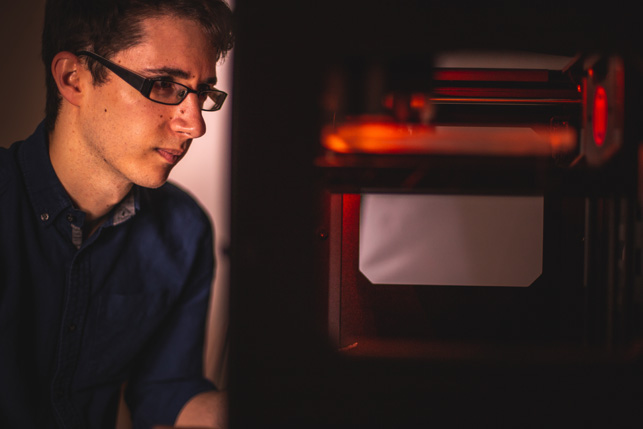

Product designer David Walling hard at work on the Dino Island playset

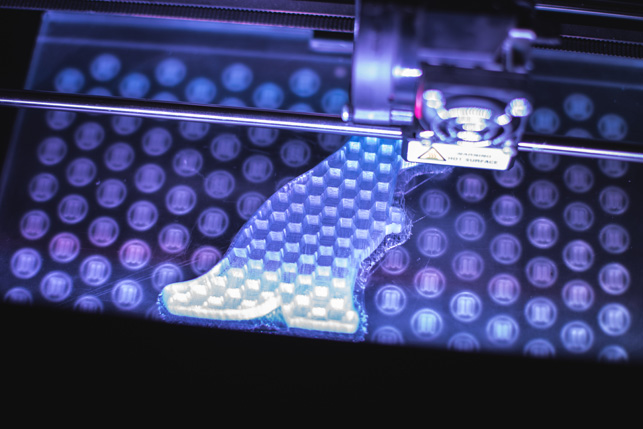

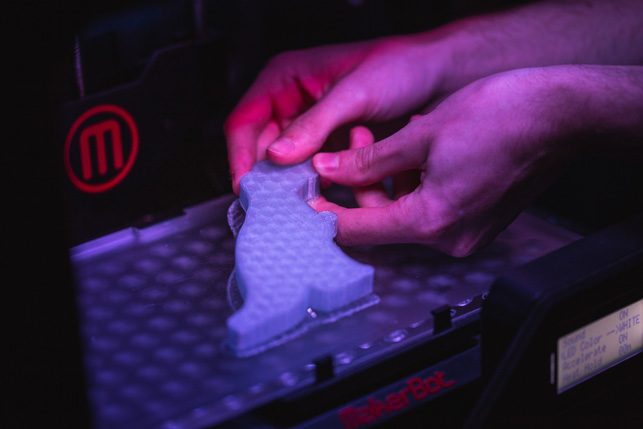

A Makerbot Replicator 2 3D printer has been useful in the design of this latest product

3D printing a T-Rex in order to check the toy’s centre of gravity

Testing size and scale

Another relatively new addition to the design office is the Makerbot Replicator 2 3D printer. It isn’t used for every project, but has proven very helpful in the design of this latest playset.

“Use of 3D printing entirely depends on the product I am designing,” says Walling. “I often print and cut out designs in cardboard to test size and scale. However, 3D printing has proven its worth in making prototypes where size is critical. For instance, with a shape sorter toy, I can test that each shape will only fit into its correct position.”

He continues: “When it came to the playset, I 3D-printed a T-Rex dinosaur, to check its centre of gravity and that it would stand up. I could have used SolidWorks for this, but it is nice to physically have a prototype to test.

I’ve also used the Makerbot to alter the first samples we get back from the factory to help check design changes before sending off for a second sample.”

SolidWorks is increasingly being used as a communication tool between the design team and the manufacturing team in the Far East. As Walling explains, 3D images and exploded views in SolidWorks have become an invaluable way of overcoming language barriers.

Once happy with the design of the playset, Walling shares the final technical files with the manufacturing team. In this case, these were DXF files, as the product was made using CNC machining.

The first sample that the Bigjigs team receives back is sent off to an independent testing house where it undergoes rigorous tests for durability, chemical and paint analysis and consideration for age-appropriate guidelines.

Importantly, it then gets tested by the users themselves, says Walling. “We have in-house testers in the form of our director Sam Ireland’s children, Arthur and Edith, who are in and out of the office, school hours permitting. They are more than happy to give their opinion!”

Get it made

Following any final tweaks and changes to the design, the final files are sent off to the manufacturers for mass production. In the meantime, the design team will work on the product’s instruction manual. “CAD has also proven invaluable here, especially for more complex designs that need to be built by the consumer,” says Walling.

“In fact, we are currently in the process of updating all of our instruction sheets. This will require toys that were previously designed on Illustrator to be drawn up in CAD.” The product’s eco-friendly credentials also extend to packaging, which is made from 100% recycled cardboard and is fully recyclable. Bigjigs also ensures that the minimum amount of packaging is used and that boxes aren’t excessively larger than the product, helping to reduce the carbon emissions involved in their transportation.

The Dino Island playset is freshly off the production line, ready for launch in early September. Much like toy trains, dinosaurs are equally fascinating to young children, but this new product seems likely to take their imaginative play in entirely new directions.

Bigjigs welcomes kids to Dino Island with sustainable toy designs

Default