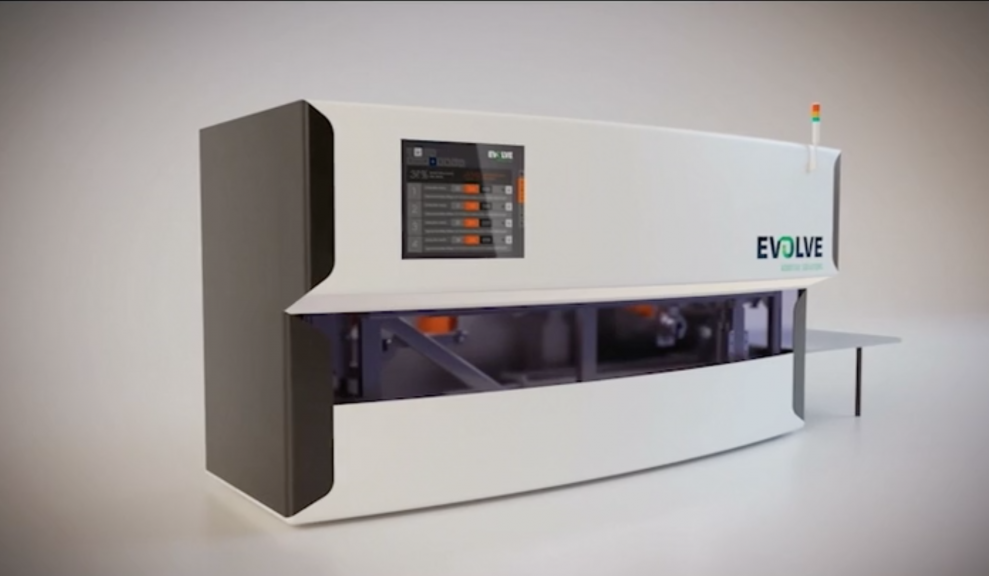

Evolve Additive Solutions, a spin-off of Stratasys’ Selective Toner Electrophotographic Process (STEP) technology, is looking to challenge injection moulding’s place in the manufacturing pipeline.

The STEP process combines time-tested 2D imaging technology with proprietary IP developed by Evolve to precisely align incoming layers and sophisticated bonding techniques that create final parts it states are ‘fully dense with isotropic properties’ of injection moulding.

Having spent nearly 10 years as an incubation project within Stratasys, the technology is billed as being up to 50 times faster than existing additive manufacturing solutions, while using engineering-grade materials.

Stratasys suggests that the technology has been designed for automated manufacturing and factory-floor integration, with STEP’s use of thermoplastics (amorphous and semi-crystalline) for volume production making it suitable for applications across multiple industries.

A scalable solution, its is said to combine Evolve’s own proprietary technology with the capabilities of electrophotographic imaging.

STEP Technology

“We are excited to introduce Evolve Additive Solutions and proprietary STEP technology,” said Steve Chillscyzn, Evolve Additive Solutions CEO and co-inventor of STEP.

“We believe the STEP Technology is uniquely positioned to bridge the gap in the market not yet addressed by additive or traditional manufacturing technologies.

“It is the first-of-its-kind technology offering an additive method for mass production. It’s designed to deliver the benefits of additive, while handling high-volume production.”