The Stratasys ‘benchtop’ F123 Series 3D printers have added carbon fibre to the materials menu, adding further value to the brand’s introductory FDM line-up.

With FDM ABS-CF10, Stratasys is looking to continue making carbon fibre much more accessible to designers and engineers wanting out of the box carbon fibre parts – as it has done previously with the full-size Fortus range.

With the accompanying QSR water-soluble support material, users will be able to produce complex parts and internal structures.

The Stratasys FDM ABS-CF10 carbon fibre material for the F123 Series contains 10 per cent chopped carbon fibre, making it a reputed 15 per cent stronger and 50 per cent stiffer than standard ABS, and a reasonable alternative to metal parts while weighing less.

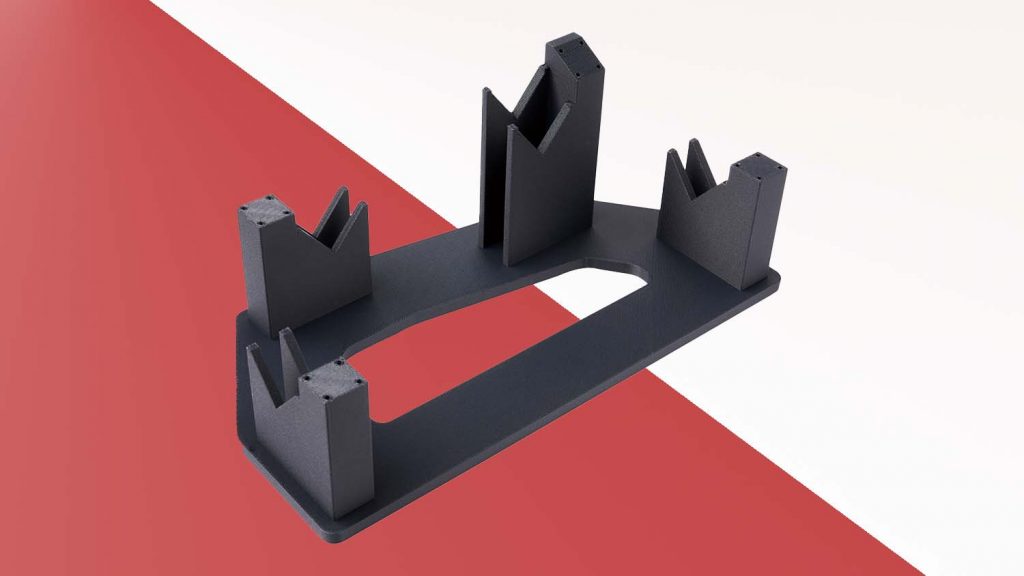

The material addition sees Stratasys continue to target its FDM technology at applications such as manufacturing tooling, jigs and fixtures.

Stratasys has released its own analysis, suggesting that the additive manufacturing market for polymer jigs and fixtures is expected to grow at a 14.2% annual rate between 2019 and 2023, to nearly $600 million, double the growth rate of the prior four years.

“There is a reason why manufacturers are increasingly turning to 3D-printed carbon fibre materials,” said Stratasys senior VP of manufacturing Dick Anderson.

“It’s incredibly strong, versatile, and lightweight. We want to enable all our FDM customers to take advantage of those material characteristics. Introducing FDM ABS-CF10 is a significant step in growing 3D printing’s presence in the global manufacturing industry.”

The FDM ABS-CF10 material is scheduled to be available in April 2021, with orders being taken now.

UK-based Marshall Aerospace and Defence Group specialises in the conversion and modification of military, civil, and business aircraft, along with defense vehicle engineering and shelter manufacturing.

The company uses its F370 3D printers alongside its much bigger Fortus 450mc which already 3D prints a carbon fibre material for a variety of tooling applications.

Chris Botting, materials and environmental engineering manager at Marshall, said: “All the tooling we create has different and often unique requirements. Our F370 3D printers offer us the flexibility to choose from a wide variety of materials based on application demands while still producing functional parts.

“3D printing parts that we historically would have made of metal has led to a significant cost reduction compared to machining the part out of aluminium, while reducing overall part weight.

“We can’t wait to begin to realise the benefits of FDM ABS-CF10 for creating manufacturing aids like we have with our other carbon fibre materials.”