PostProcess Technologies, a pioneer of automated post-print solutions for industrial 3D printing, announced today its Connect3D software platform, an expansion of its Automat3D software offering.

Where Automat3D powers the intelligent removal of 3D support materials and surface finishing, the new Connect3D platform extends this capability into the cloud for the first time, allowing the digital thread for smart additive manufacturing to move beyond design and print, all the way through to the final post-printing step.

Connect3D allows PostProcess solutions to leverage the native CAD-file or 3D printer sliced files to automatically define the necessary requirements and algorithms for post-printing – allowing the software to become progressively smarter and more efficient in the decision-making required to deliver optimal post-printing results.

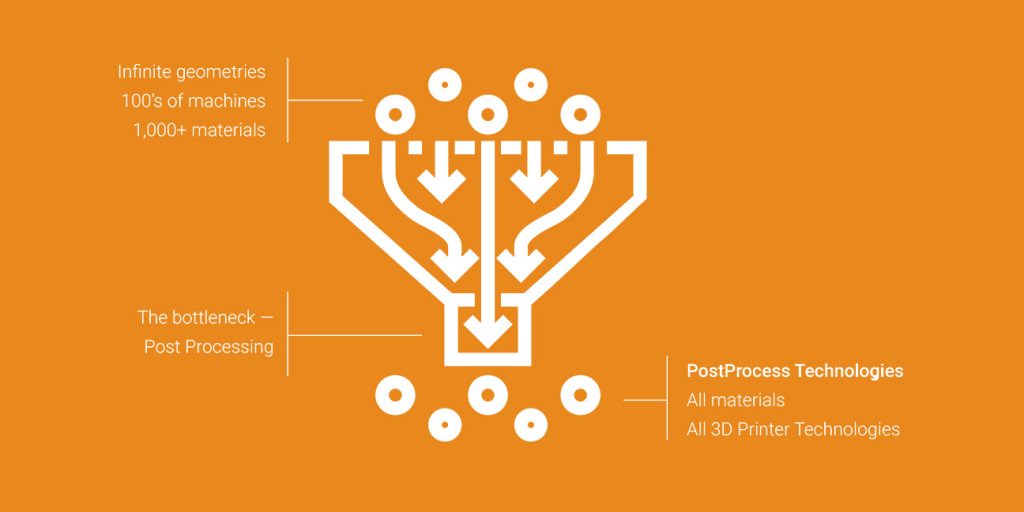

“Currently, the concept of the ‘digital thread’ within additive manufacturing ends once parts are printed,” explained PostProcess founder and CTO Daniel Hutchinson. “Conventional finishing processes rely on tribal knowledge and hand tools so there is no ability to collect or transfer data.”

“The lack of transferable data limits the post-print process, but also fundamentally weakens the design process. Design input decisions, such as part orientation, are undermined due to a lack of downstream process data. Critical areas such as maintaining strength along a preferred axis and minimizing the amount of support material are jeopardised.

“This is revolutionary for additive manufacturing in its entirety, not just post-printing.”