The E3D RapidChange Revo range has been launched with the aim of making FDM 3D printing more accessible and making more entry level desktop 3D printers less hassle for users, by allowing for quick and easy nozzle swapping for different 3D printing requirements.

Compatible with desktop FDM 3D Printers from Ultimaker, BCN3D, Lulzbot, Prusa and more, ease of use is at the core of the new product range.

Traditionally, changing 3D printer nozzles needs specialised tools and hot tightening, a process that is both time consuming, physically demanding, and not without its hazards.

The new Revo ecosystem has been designed with the aim of accessibility: to change a nozzle with the new Revo design, the nozzle can simply be unscrewed with fingers at room temperature, to then be replaced by screwing in a new Revo Nozzle.

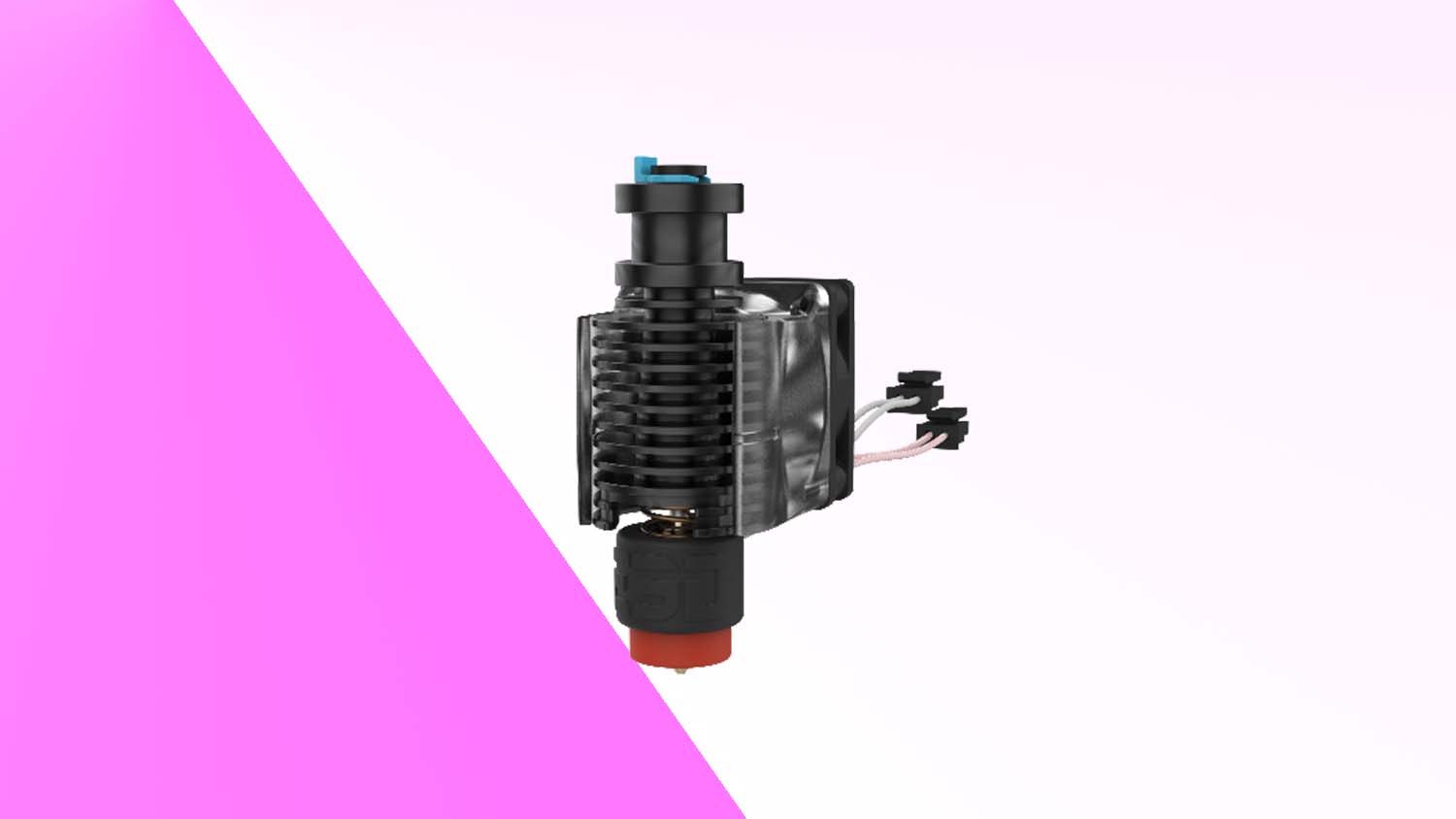

The new RapidChange Revo components; initially the Revo Six, Revo Micro, Revo Hemera, Revo sock packs, plus four sizes of brass Revo Nozzles. These parts will be sold individually and as ‘fully loaded’ kits so users can get up and running quickly with all the required components.

Each Revo nozzle carries a colour-coded silicone sock and is metal-engraved with easy-to-read numbers for fast identification, with sizes covering the most popular 3D printing use cases.

“The initial thoughts behind this new ecosystem actually developed a few years ago,” said E3D lead hotted engineer Rory Yonge.

“By analysing the main pain points of existing systems, and listening to customer feedback, it was clear that the process of changing nozzles was far too difficult. This was especially the case for members of our community that have existing physical difficulties and disabilities.

“It required plenty of challenging work and patience from everyone on the team to move from the initial concept of making 3D printing more accessible to the design and development phase. We knew we had to get this 100% right, as the concept is so vast, as well as redesigning essentially every component that we currently produce.”

Yonge says that E3D has already has feedback from testers with physical disabilities, who have commented on how easy it is to change the nozzles relative to the traditional ecosystem. “Being able to make such a big difference to someone’s life in this respect really spurs us on, and shows we are doing something right in our overall mission to make 3D printing accessible to everyone, no matter the restrictions placed on physical abilities,” concluded Yonge.

The new Revo Six has been designed as a drop-in replacement for the existing V6 model, so there is no need to adapt the design of the 3D printer to accommodate the new RapidChange ecosystem; if a user’s printer uses the V6, then it will be able to use the Revo Six.

Other main developments in the new RapidChange Revo ecosystem include the safety aspects.

E3D head of marketing Clare Difazio, commented: “The new Revo HeaterCore has been designed with a positive temperature coefficient, meaning that as the HeaterCore gets hotter, the power is reduced. This massively reduces the safety hazard of an overly hot component, for instance, in the event of a thermal runaway.”

Finally, the Revo Micro has been designed as the lightest HotEnd E3D has produced, weighing in at just 30 grams. The manufacturing process behind it enables the strength and low thermal conductivity of titanium in a small form-factor.

Difazio adds: “Being an extremely lightweight and compact HotEnd, the Micro is ideal for extra motion system speed, or experimenting with the process of 3D printing. For those looking to start their 3D printing journey, the Revo Micro is perfect for exploring.”

E3D suggests that further additions to the Revo ecosystem will be announced in early 2022.