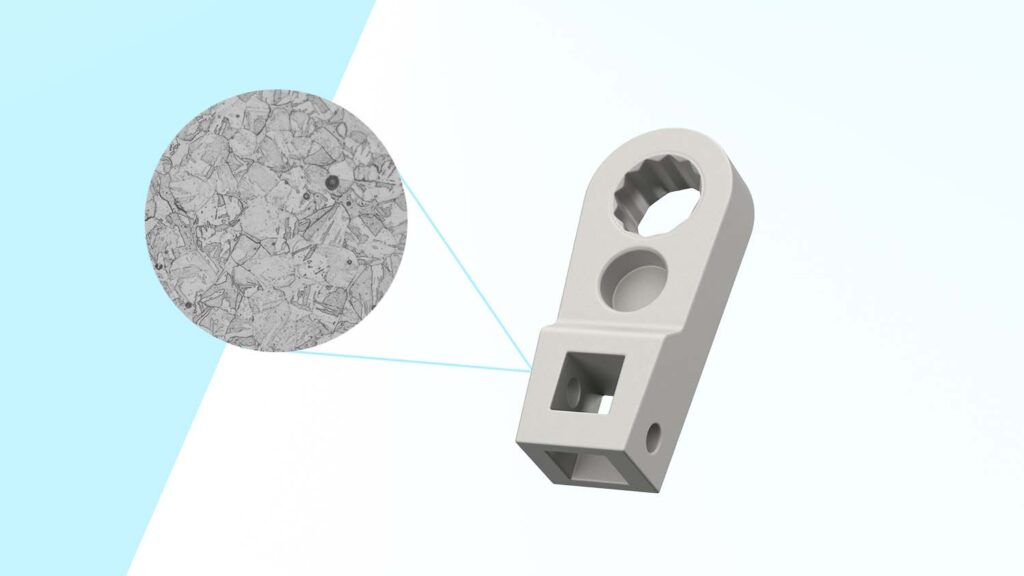

Desktop Metal has released DM HH Stainless Steel for its 3D Production System 3D printer, making the custom stainless steel alloy that combines high strength and hardness with corrosion resistance the tenth material qualified for the additive manufacturing system.

Desktop Metal says that its HH Stainless Steel is heat treatable, allowing it to combine the tensile strength, ductility, and corrosion resistance of 13-8 PH stainless steel with the added benefit of improved hardness comparable to low-alloy steels, such as 4140.

The alloy should help companies looking to reduce the amount of low-alloy steels, which also require a subsequent plating step for applications needing corrosion protection. The new 3D printing material is also ideal for conformally cooled injection tool core and cavity applications, where millions of injection strokes per year are required.

“Our materials science team is working diligently to develop innovative materials that meet the demanding applications needs of our customers in a cost-effective way,” said Desktop Metal CTO Jonah Myerberg.

“DM HH-SS is a compelling alternative to 17-4 PH stainless steel that improves upon its mechanical properties while maintaining corrosion resistance, making it suitable for critical components that previously required the use of low-alloy steels for their high hardness and strength. The Production System allows customers to go to market at scale with this material and eliminate operations, such as plating, which can create supply chain complexity and also be harmful to the environment.”

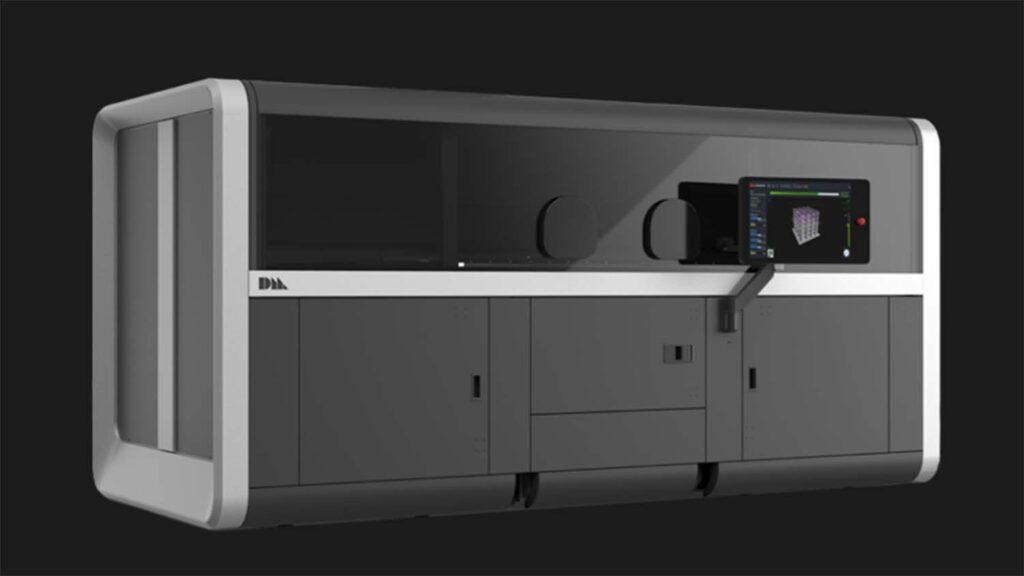

The Production System platform consists of two printer models: the P-1, a solution for process development and serial production applications, and the P-50, a large form factor mass production solution for end-use parts.

Desktop Metal engineered binders can be combined with an open material platform, allowing users to produce parts using the same low-cost metal powders used in the Metal Injection Molding (MIM) industry. An inert processing environment enables compatibility with a variety of materials, including high-performance alloys and even reactive metals, such as aluminium and titanium.