Stratasys is sending a selection of 3D printed materials to the surface of the moon to test their performance in space as part of Aegis Aerospace’s upcoming lunar mission.

Two different experiments including three samples provided by Stratasys will be conducted by the unmanned lunar mission.

The first experiment will focus on the performance of a sample made with Stratasys’s Antero 800NA FDM filament filled with tungsten.

It is a PEKK-based thermoplastic with added tungsten intended to provide shielding against potential harmful radiation.

The second experiment will focus on how two other 3D printed materials perform in space.

The first material will be Antero 840CN03 FDM filament, which was used on the Orion spacecraft.

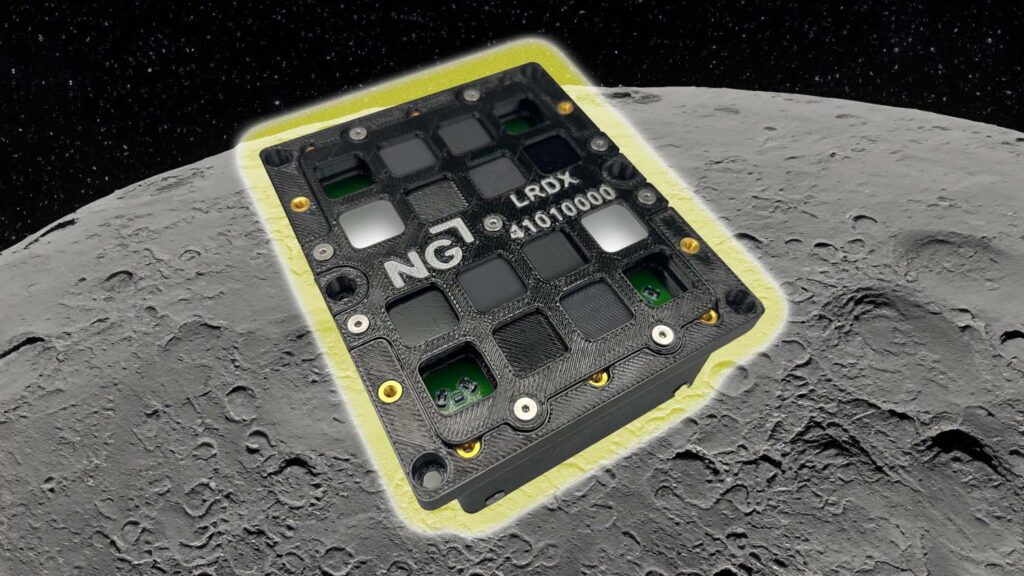

The second material will be a new ESD photopolymer resin manufactured by Stratasys partner Henkel for use with Stratasys’s Origin One 3D printers. The samples will be sent to the moon in a carrier that is 3D printed from Ultem 9085 thermoplastic.

The Aegis Aerospace Space Science and Technology Evaluation Facility is conducting the experiment under Nasa’s Tipping Point programme in order to develop technology for space infrastructure and capabilities for the moon and near-earth space.

This tests will subject the samples to moon dust, low pressure and rapid temperature swings, which take place due to the moon having a very thin atmosphere.

“This set of experiments will help us understand how to fully leverage 3D printing to keep people and equipment safe as we travel to the moon and beyond,” said Stratasys chief industrial business officer Rich Garrity.