Läpple Group has spoken about how it is using MakerBot’s desktop FDM 3D printers to train its engineers on the production of complex-shaped parts using additive manufacturing, resulting in tangible benefits straight away.

The German automotive supplier’s renowned vocational program was established for over 80 years and today is helping educate its engineers using the Using MakerBot Method and Replicator Z18 3D printers to complement their technical product design course.

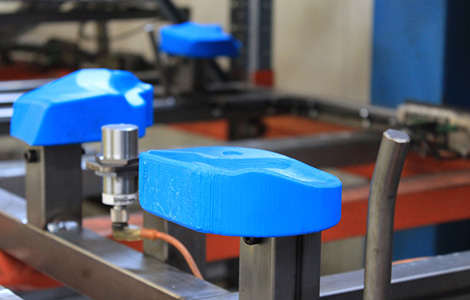

Using desktop FDM 3D printing, students learn to import CAD files, auto-arrange and print on one or multiple printers, offering instant conversion and realisation from design to prototype, with the output resolving recurring issues with fixtures and tooling, and reliably print components which are difficult or impossible to produce with conventional methods.

Martin Heckmann, development engineer at Läpple, said “Should a print not turn out as desired on the first attempt, we just try again. The extremely low print-costs per unit in the MakerBot allow us to adjust the parameters until we get a perfect result.”

By upgrading its training in such a way, Läpple has reduced lead times and costs by up to 50 per cent compared to its traditional manufacturing methods for specific production appliances, and has managed to eradicate the need for off-tool sheet metal parts in fixture manufacturing – instead using 3D printed parts.

“Läpple has embraced the possibilities that in-house 3D printing can offer, especially when engineers design and think with additive in mind!” said MakerBot CEO Nadav Goshen.