Born from a young couple’s desire to democratise additive manufacturing, Makelab is a 3D printing bureau like no other. Makelab CEO and co-founder Christina Perla talks to Claudia Schergna about the company’s values and vision

Upload. Print. Collect. That’s how most print shops work today. What if 3D printing could be just as straightforward?

This is the mission behind the 3D printing service bureau Makelab. Based in Downtown Brooklyn, New York, Makelab is very unlike your typical printing facility. Small, bright and spotlessly clean, desktop 3D printers and post-processing machines are arranged neatly on shelves around the lab. A small dog wanders around the office, while the staff chat over their lunch.

“Makelab is a different concept,” says Christina Perla, confidently. The Makelab CEO met Manny Mota, her co-founder, at Pratt Institute, where she was an industrial design student, and he was working as a shop technician. When they first approached the additive manufacturing (AM) industry, they quickly realised that most services were inaccessible for small businesses, freelancers and students.

Some years later, having established themselves in the industry, they came to recognise that the gap in the market that they had spotted as students was actually more like an abyss.

Makelab // A modern approach

Repeatability and profitability are the pillars on which the Makelab business was built, Perla explains. Local service, an open-door policy and face-to-face contact are what attracts customers and “makes them stick”, she says.

The relationship with customers, meanwhile, is always post-order: “We are not a consultancy,” she clarifies. “Most of our orders come from direct print online.”

An analogy that works with investors, she says, is to position Makelab as an AM version of the Kinko’s chain of copy shops, now part of FedEx. While there are clear differences, she adds, “it really explains the multilocation play that we’re going for, the hyperlocal presence and the culture we have here.”

Another similarity is that, for Makelab, no order is too small. Most customers will submit an order quantity of one at first, because it involves the lowest risk. Once they have the results in their hands, they frequently go on to order larger quantities.

Makelab’s most recent projects range from kitchen tools to supports for card games, from jewellery to packaging, and from fem-tech to art installations.

Having such a wide customer pool can be a doubleedged sword. On one hand, it brings more business opportunities. On the other, it might lead to scepticism, given that other bureaus often specialise in serving a single industry. “The risk is that we might look unfocused,” says Perla.

“We try to attract creative souls, which is a niche. I don’t think many people in the industry do that.”

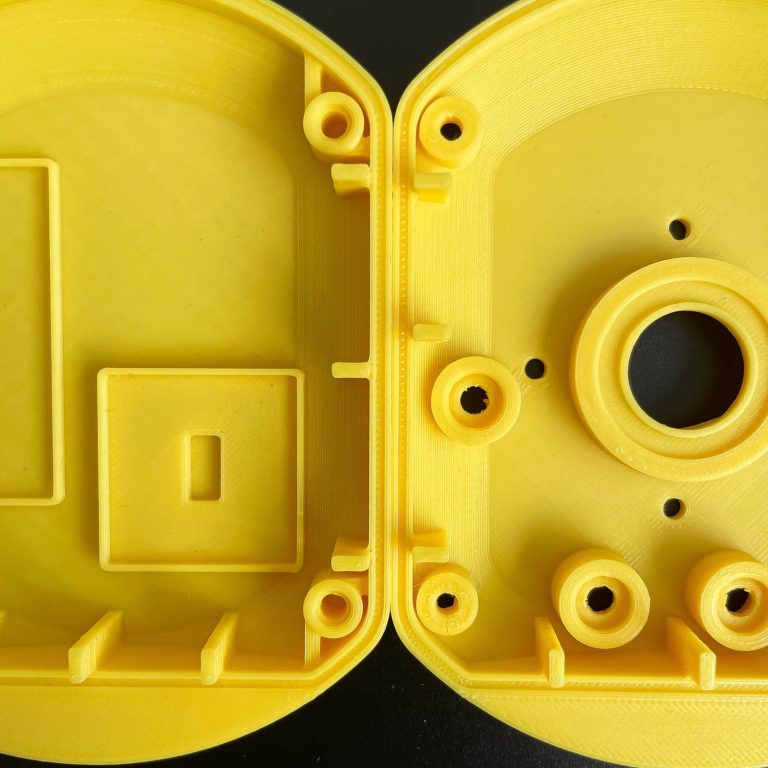

Another thing that sets Makelab apart from other bureaus is the fact that it doesn’t own any ‘industrial’ 3D printers. While Perla doesn’t rule out investing in these at some time in the future, she says that desktop alternatives offer many benefits without compromising on quality.

“I think the desktop has its place. And when you’re thinking about profitability, smaller modularity and repeatability, this stuff shines,” she says.

“I’d much rather have 34 of these than two big industrial ones,” says Perla, indicating Makelab’s Prusa i3 FDM printers and its Form 3 SLA printers from Formlabs.

When setting up the company, Perla and her team worked on five different types of machines. Moving forward, they decided to stick with Prusa and Formlabs, based on the alignment of values and roadmap between Makelab and these suppliers.

A simplified process

“Printing is actually the easiest part of the business,” explains Perla. “We know the set of materials. We know what kind of files we’re going to see. We can predict what kind of printability issues we’re going to run into, and know how to solve them.”

Before going to print, Makelab will make a few tweaks to ensure that the print is successful, using Solidworks and Materialize Magics. “We do draw a line between creative direction and just 3D modelling for customers,” explains Perla. “We believe that the customer should own their own creative process.” Customers then select materials, set their timeline, check out and pay.

Fast delivery and collection times – which range from next-day to seven days – are another core element of Makelab’s vision: “We want to be designers’ and engineers’ right hand, be their teammate. You don’t say to your teammate, “I’ll do it next week!’”

If efficiency, automation and repeatability describe Makelab’s approach to production, ‘customer-centric’ is how the company sums up its culture. It’s also focused on community, an ethos reflected in its hiring process. Makelab’s team is expanding fast and diversity, in terms of gender, race, age and background, is a central pillar.

“Our team ranges in age from 20s to 60s, and I love how diversity informs decisions,” says Perla. “We’ve gone very purposefully for people who will challenge each other.”

Being a woman of colour in a male-dominated industry, it wasn’t easy for Perla to make her mark as CEO: “At the beginning, I was more intimidated. Now, I lean on my strengths and on what I bring to the table,” she says.

Besides her work leading Makelab, Perla has also served as the New York ambassador for Women in 3D Printing, a community that aims to inspire and support women in the industry and that campaigns to increase diversity and close the gender gap.

Considering the speed with which Makelab has expanded in the past few years, Perla is confident that the future holds great things for her company. In five years, she predicts, Makelab will be on its way to being “one of the most well-known brands in the additive manufacturing space.”

What makes her business successful? It’s not down to one big thing, she says: “It’s all the small things.”

These ‘small things’ include a strong online presence, a community-based culture and a modular work environment that can be replicated in other locations. (Next stop: a new, identical workshop in Manhattan.) But above all, it’s an innovative vision that aims to democratise and simplify 3D printing, transforming it into that upload/ print/collect experience.