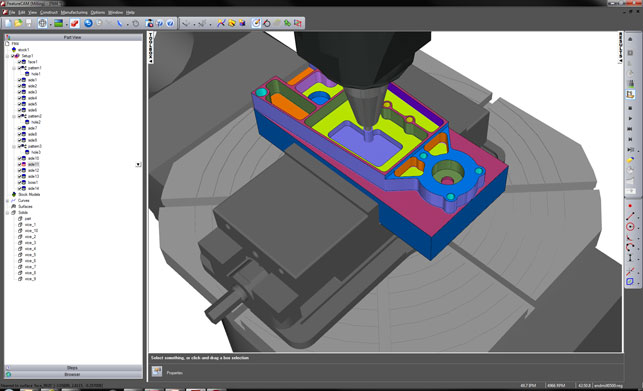

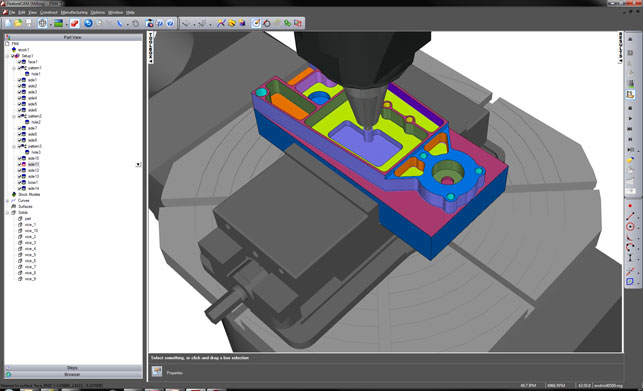

FeatureCAM is one of the many CAM systems that Delcam has in its arsenal.

Delcam has added a new 3D milling product in FeatureCAM 2013

Since it acquired the software back in 2005, the system has been growing in terms of capability and has also seen a lot of work done on user interaction.

If you’re not familiar with FeatureCAM, it differs from Delcam’s other CAM systems in that its goal is to provide the quickest route from getting CAD data (either as a drawing or a 3D model) to cutting on the machine.

While the likes of PowerMill focus on surface quality for the mould and die market, and PartMaker concentrates on optimising toolpaths for large volumes of the same product, FeatureCAM is meant to be more general purpose.

The typical use case is one where parts are low to medium in volume, not necessarily massively complex, which means that the bottleneck then becomes the toolpath programming process, rather than the machining itself. Get the job, program the part, machine it and ship it. That’s the goal.

Also, unlike some of Delcam’s better known applications for manufacturing, FeatureCAM (as you may guess from the name) is focussed on pulling geometric features from the CAD model (or indeed, sketch) and using that data to automate the toolpath creation process.

Its capabilities run the gamut of most production machining processes, from 2.5 to 5 axis milling, through tombstone, turning, mill/turn and into wire EDM.

General updates

If we start with the generally applicable updates to FeatureCAM, anyone with experience of previous versions will see that the company has been working hard on modernising the user interface.

It’s now clean, fresh and sensibly laid out. All of the core operations and commands are immediately available and it’s pretty easy to dive in and get working.

Other general updates include changes to the tool library, which is now much more graphically rich, so you can pick the optimum cutter more quickly.

Work has also been done on the set-up sheets that the system generates. These now extract information from the files and allow images to be taken for each set-up, as well as the finished part. These are available for all machining operation types.

There’s also a key change to how you can work with other team members and move data around.

The new “Send” command allows you to capture everything that relates to the job (parts, operations, libraries etc.), collect it together and zip it up into a single file that’s much easier to handle.

Stock model

Stock models are key to machining efficiently. New functionality eliminates excessive tool engagement and limits the maximum depth of any cut into un-machined material.

Both these controls reduce tool wear and improve surface finish by avoiding any overloading of the tool.

In addition, a new “detect material thicker than” command ensures that rest material thinner than the specified limit is ignored. This prevents toolpaths being generated in any areas where the benefit of the extra cut is negligible, such as cusps left by the previous toolpath.

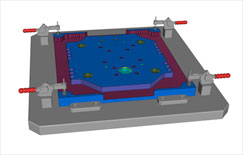

Fixture avoidace in 2.5

Fixture avoidance has also been improved for 2.5 axis machining. In previous releases, the system required that you sketch out a boundary that defined an envelope around the part. From 2013 onwards, you simply define the 3D models as “collision check” faces and the system will avoid them.

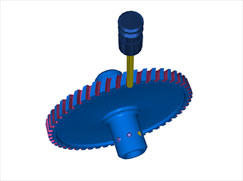

Five-axis

The last few releases have seen the introduction of more five-axis toolpath capability into FeatureCAM.

This has continued with the addition of five-axis control for machining between two curves, pencil machining and corner re-machining. These options for simultaneous five-axis machining allow a better surface finish to be achieved as well as ensuring access to more areas within the part in a single set-up.

Mill/turn updates

The key update for this release is how the system handles part transfers in mill/turn operations.

Previous releases required that transfer was added manually and individually integrated into the operation set.

This is now more automated and fully encoded into the product. Parts can be transferred by slug or reverse slug; bar pull for feed stock can bring in support where needed and part cut off operations can be added.

Complex part machining

Again, the last few releases have seen more 3D form machining introduced into the system. The packaging of this has changed somewhat.

Previously, there were two packages available — 3D Lite, which allowed single surface machining, and 3D HSM which has all the bells and whistles you’d expect.

There’s now a mid-way between the two — 3D MX. This gives you three-axis machining of multiple complex surfaces, without the high speed machining options.

There are also functionality updates that bring a new ‘step-up machining’ operation that minimises terracing when roughing. The feed rate increases as the depth of cut gets progressively smaller which enables a more consistent volume removal rate.

Conclusion

FeatureCAM is a system that’s intended for production machining. As we said at the outset, the goal is to get the material on the machine and to start cutting as quickly as possible. This is accomplished by automating and taking advantage of feature recognition where possible.

What’s interesting is how technology from other areas of Delcam’s expertise is coming into play.

The introduction of more complex machining operations (particularly 3D surface machining) is bringing new capabilities, while retaining that ethos of efficiency.

The introduction of both the stock model updates, probing and various other bits and bobs mean that the efficiency in the programming process, is now backed up with tools that allow more reliable and automated toolpaths to be created and run.

Machining is a complex business. Some specialise in producing highly complex components (I’m talking mould and die and the like), some specialise in very high volume parts.

There is also a huge industry that centres on the production of less complex parts, in lower volumes. All have very different dynamics and requirements for running their businesses efficiently and serving their customers.

FeatureCAM is a system that’s targeting this group of users. It also allows for the fact that many are looking to upskill and expand their capabilities so it provides a single set of tools to assist this process.

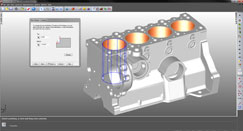

Inspection and probing

One of the big focus points for this release is the ability to integrate inspection and probing routines into the tool paths, both for milling and mill/turn machines.

The aim is that you can take the tool path and add in inspection routines that will verify the progress so far. The end goal is to allow users to define processes for complex, geometrically rich components that can be run in a lights-out, unattended manner.

The process begins with programming the tool paths as per normal, using feature recognition of pockets, bosses, corners and such. Once done, you add in “in process decisions”. These will use machine mounted inspection probes (remember, inspection hardware wizards, Renishaw have a stake in Delcam).

The probing routines will check the feature, find any problem areas, adapt the tool path if possible and, depending on the result, allow it to continue or if the problems can’t be rectified, the job will cease — obviously saving time wasted on attempted rework.

The key task is to build up a set of decisions based on activity (machining) and measuring that will either get you to your final object or will stop the machines running and wasting time. It’s not always a simple task to set-up, but you have a great deal of flexibility.

If you can think of it, you can probably do it. Whether that’s checking positions of parts or fixtures, measuring remaining stock, setting tool offsets, changing tools or re-cutting. It’s all there to play with.

| Product | FeatureCAM 2013 |

|---|---|

| Company name | Delcam |

| Price | On application |