Meshless simulation has experts impressed, but can it really deliver a successful merger between the worlds of simulation analysis and product design? It’s doubtful, according to regular contributor Laurence Marks

For years, people have talked about meshless simulation as the future. Various systems have entered the market, in various guises, all waving the meshless banner. But it’s fair to say that none of these have so far had much impact on the average designer or engineer’s view of the world.

Yet things seem to be changing. Super experienced simulation analysts now report great advances in meshless technologies – and if there was a group you might expect to be all about the meshing, it’s them.

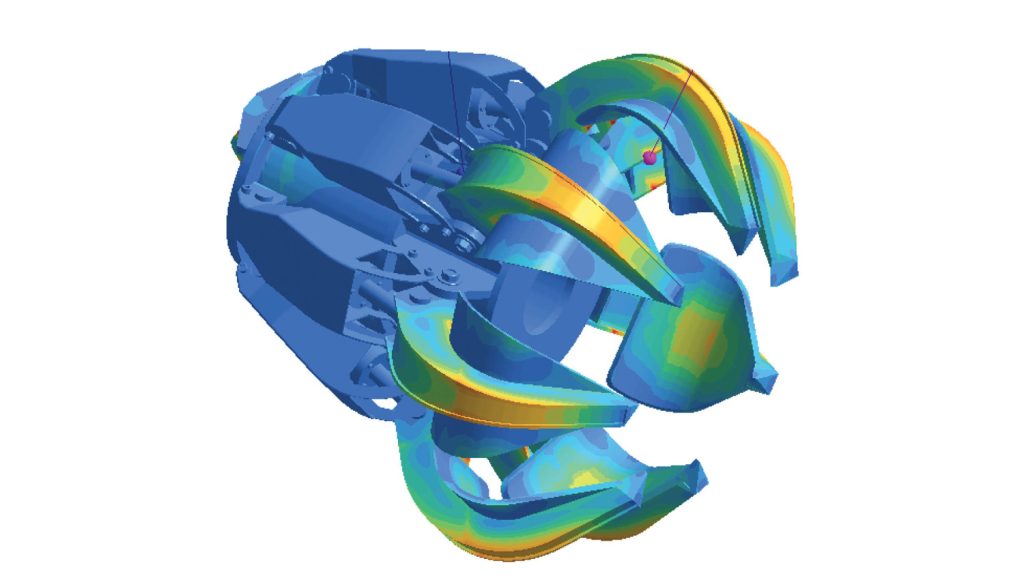

So, what are they saying? Well, they say you can set up models in a super-quick time; that automatic set-up on interfaces is reliable; and that you can get a credible solution very rapidly. And don’t forget that these are the sort of people who check this stuff to the nth degree.

Meshless technologies have evolved from ‘promise-high, deliver-low’ solutions to systems that actually work, even in the demanding world of the professional analyst

Obviously, the software has evolved from ‘promise-high, deliver-low’ solutions to systems that actually work, even in the demanding and ubercynical world of the professional analyst.

This has got me thinking about products from the 1990s, and in particular, the new CAD integrated simulation tools such as Rasna, CosmosWorks, Designspace that were greeted with restraint by the expert community.

If you aren’t old enough to remember that far back, it was thought that these tools could be responsible for aircraft falling from the air, for cars failing at critical moments, and for meltdowns at nuclear power stations – all sorts of calamities. A career highlight for me was being asked, “How can you sleep at night, selling a system like this?”, during a NAFEMS conference Q&A session.

These calamities largely didn’t occur. Some near-disasters did happen, but not because designers could finally get results themselves from a finite element analysis.

What actually transpired was that designers bought these systems but then avoided using them in critical solutions, because for all sorts of really good reasons, they didn’t feel comfortable or empowered to make critical decisions.

They generally left these to the experts, who are now finding many of the benefits of this sort of UI methodology, now powered and enabled by meshless.

Do it yourself?

Where things may have changed is in the actual understanding of the solver technology by users. During the 1990s, I got so sick of others boasting of how they had written their own solver that I simply got on and wrote my own. It was a lot of work just so that I could say “So did I,” – but it was worth it. I’m that sort of person.

The point here is that any better-than-average FEA user in the 90s could probably have written some form of FEA solver. Not a great one, to be sure – but they’d have known where to start and how to finish.

But a meshless solver? That’s not something an average FEA user could start, finish or even contemplate writing. And recognising this gives you a very different perspective on the technology and how you use it.

The meshless bit really is the enabling technology. After all, it’s not the core technology that matters. As long as it works, it’s relevant and therefore useful. It’s how that technology integrates with the overall simulation and design workflow that is ultimately the true metric of success.

Does this spell the end of the near ubiquitous automatic tetrahedral mesher and sparse iterative solver technology? And does this mean that the world of the professional analyst is merging with that of the designer? The answer, in both instances, is almost certainly not.

One thing I’ve learned in the world of simulation is that big shifts in technology are rarely followed quickly by equivalent levels of adoption or changes in roles. And for some reason I’ve never really understood, people are typically happy fighting with an inferior but familiar technology, even when altogether better solutions are readily available.

Overall, this highlights one aspect about simulation, simulation engineers, and their role within projects and organisations – and that’s that progress with software is often not about software at all. Instead, it’s about understanding real-world structures and real-life ‘pull it until it breaks’ materials. If you don’t have that understanding, then the choice between mesh and meshless is irrelevant.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here