E-bikes are in high demand, but reliable batteries are essential to make them both safe and sustainable. KTM has worked with Ansys and CADFEM to push its batteries to their limits, as Emilie Eisenberg reports

A dirt bike is built for the back roads, to scramble over gravel and dirt as the undisputed off-road speed machine. KTM aims to heighten the dirt bike’s appeal by matching its agility with expert electric power delivery, lower fuel costs, decreased maintenance and a significantly smaller carbon footprint.

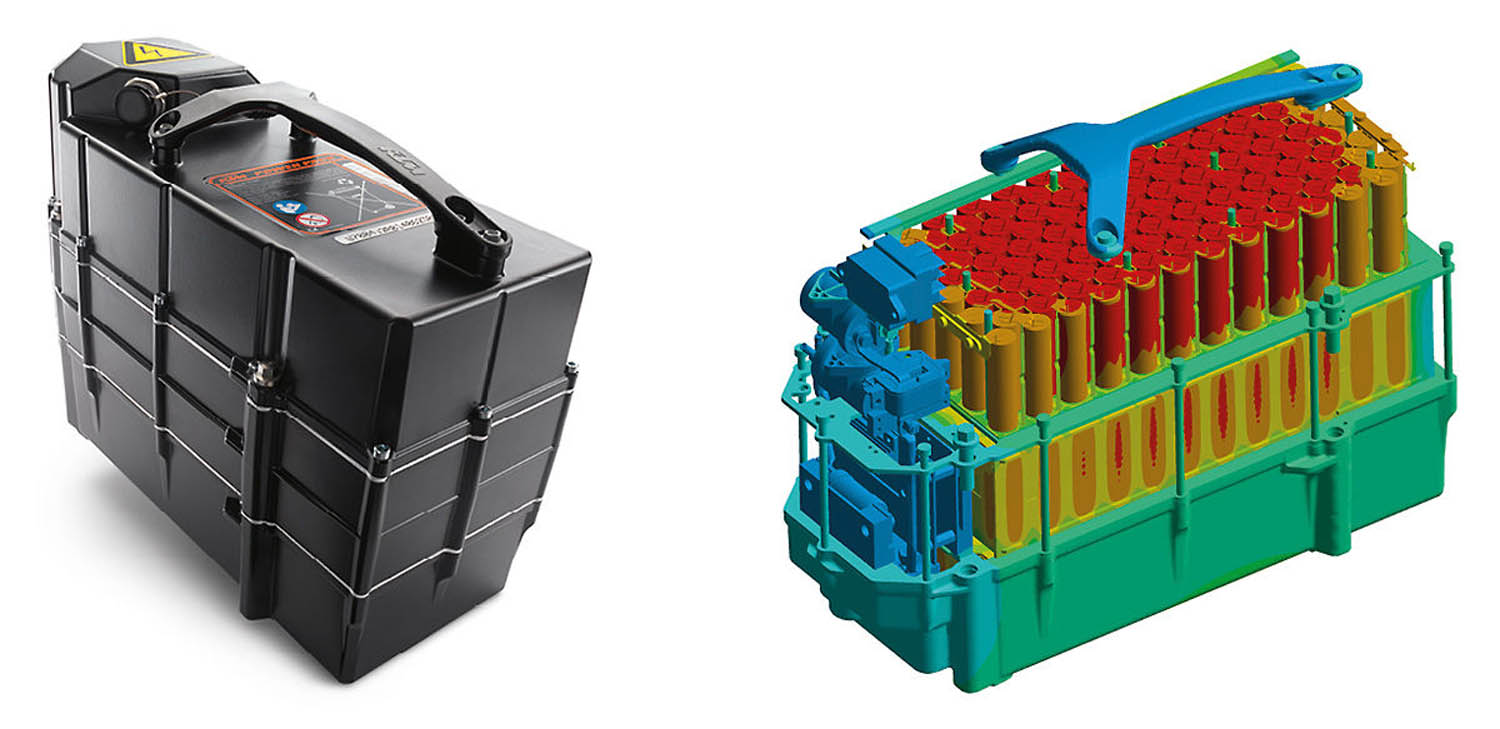

A key component in this mission is the battery. Here, KTM uses simulation technology to test batteries according to the various situations that a dirt bike might encounter.

Working with German simulation expert CADFEM, KTM’s engineers looked to optimise its battery design’s thermal properties. A well-designed battery offers faster charging times, a slower ageing process through better temperature distribution, and crucially, will not overheat.

To meet these needs, KTM developed a simulation workflow using Ansys Twin Builder. This consisted of three submodules that all exchange input and output data simultaneously.

Heat generation

An electrical lumped element model was used for heat generation to test each cell’s temperature and its state of charge. Resulting values were then fed into a compact thermal model derived from 3D finite element method (FEM) models, which calculated the battery’s temperature distribution.

A third sub-module was created based on computational fluid dynamics (CFD) analysis to calculate thermal dissipation of the battery housing resulting from convection and radiation.

KTM used Ansys Mechanical via CADFEM for model order reduction and imported the reduced order model into Twin Builder. CADFEM’s tool Model Reduction Inside Ansys was then used for accelerating computation times during reduced order model extraction without a loss of accuracy.

Reduced order model verification within the battery pack was accomplished using simulation of a 3D model of the battery to track the accuracy of, and determine the optimal parameter settings for, model order reduction.

KTM conducts all its cell testing in-house and the testing for the new e-bike battery created the need for a cell database containing every option for each project. It used the Battery Wizard toolkit in Twin Builder to generate Equivalent Circuit Model (ECM) lookup tables from all the test data in its database.

This system gave designers the ability to analyse cell data easily and quickly. Once single-cell ECM tables were created, the wizard connected cell ECMs in parallel according to specifications to configure an accurate electrical model for the battery module.

Matching the simulation model against experimental test data involved current and dynamic discharge measurements. In a single cell, the predicted output voltage showed an error of less than 20 millivolts.

For the entire battery pack model, a temperature deviation of less than 2 degrees Celsius was achieved for certain drive cycles, resulting in a stable battery pack design.

Once implemented in Twin Builder, KTM’s model of the battery pack could simulate real-world drive cycles, predicting results and heat transfer. With the virtual model, KTM can evaluate the qualities of different design proposals, optimising the airflow around the battery.

By creating the best battery packs possible, KTMs dirt e-bikes can ride harder and faster for longer with many more recharges yet to come.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here