Every year, engineers at BMW Motorrad, the motorcycle division of German automotive giant BMW, estimate the number of new crankshaft models they will need in order to build products.

From there, they can make important budgetary decisions around the procurement of these components: which suppliers should be chosen, for example, and the price they should be paid.

In the past, this process has come with some challenges, since crankshaft model building was outsourced to external providers, with the average time taken for a model varying between one and two weeks, depending on engine type.

Often, actual production of the number of models would fall short of estimates, due to constraints on the part of suppliers.

In addition, order processing times for additional crankshaft models were often too long.

In order to make budgetary planning and decision-making easier, BMW Motorrad needed to find a way to create production forecasts with a higher degree of confidence.

One employee had a suggestion, based on their experience at another facility: Altair’s SimLab simulation environment, they said, might provide an answer.

Rethinking approaches

Altair was chosen by BMW Motorrad as a development partner in order to explore alternative approaches.

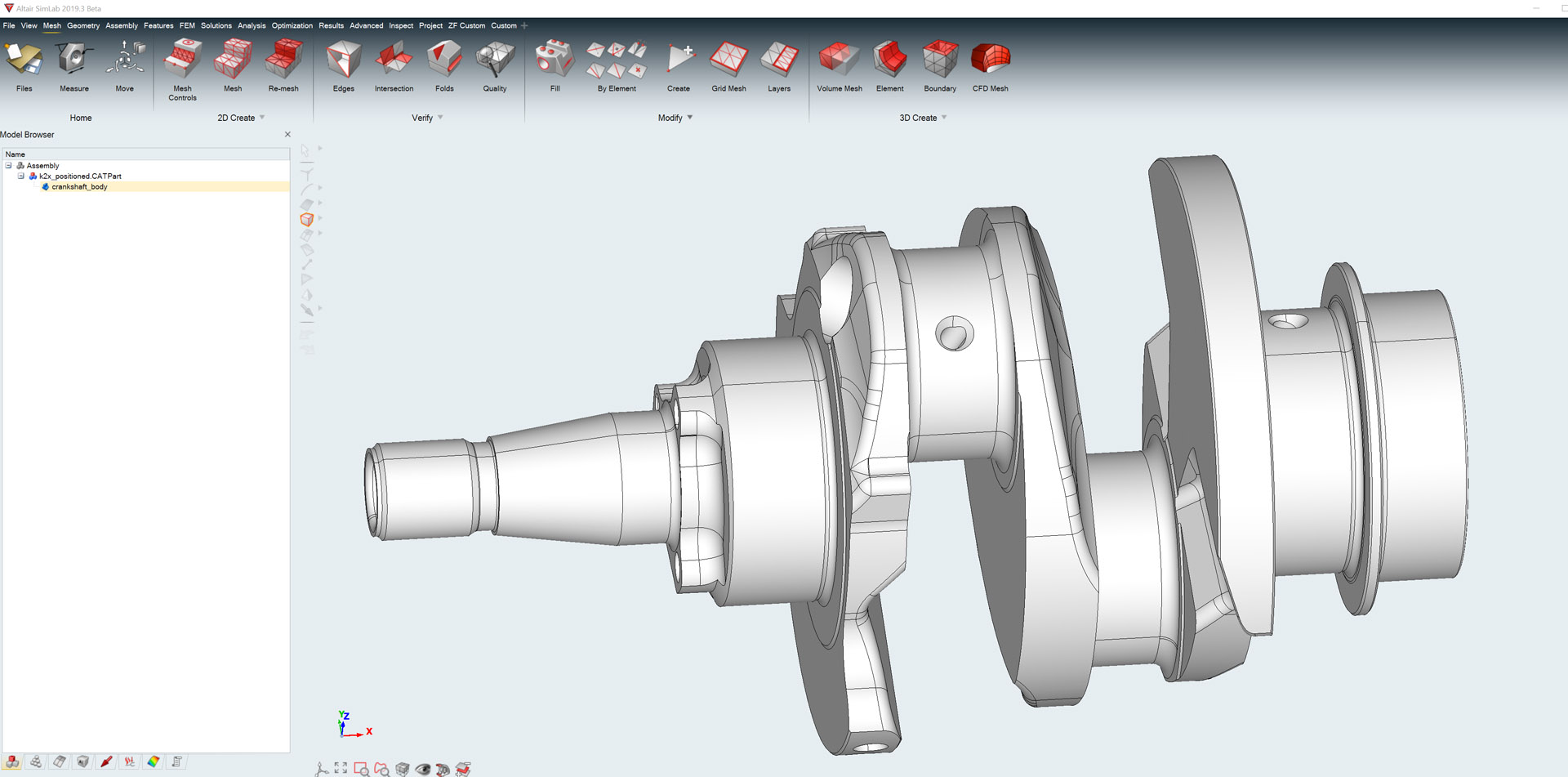

For an initial project, the preferred course of action at BMW was to clone its established approach, duplicating a previous vendor’s process and building models, without using all of SimLab’s available features.

In parallel, however, Altair engineers developed the same model using SimLab technology and then demonstrated the process to BMW.

Since motorcycle crankshaft simulation uses a detailed FE-mesh for structural and fatigue analysis, the idea was to establish a process for automated crankshaft meshing in SimLab, thus eliminating the lengthy time lags associated with FE meshing.

That kicked off a second project, whereby the established process was migrated to a complete SimLab process.

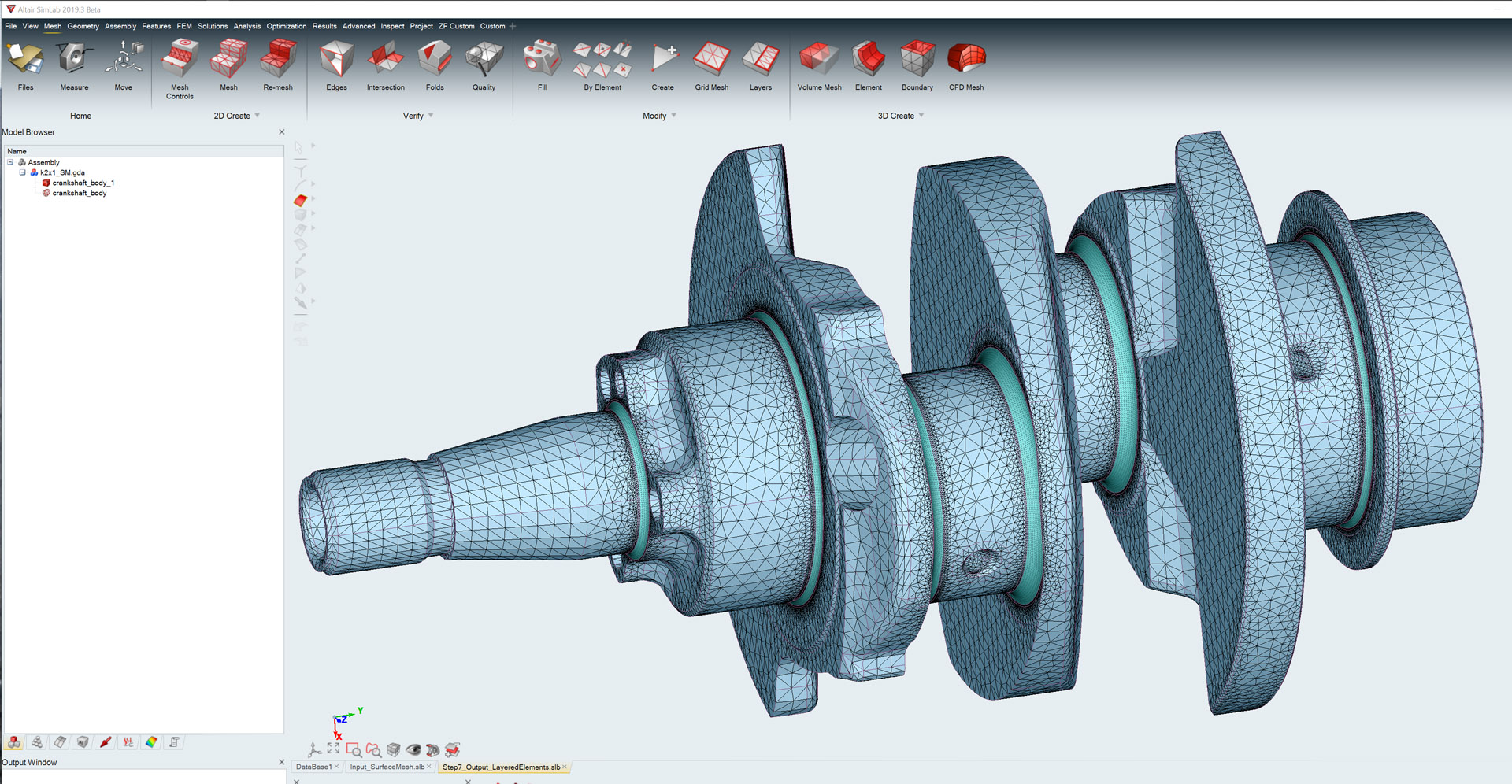

Using the SimLab process, BMW Motorrad has reduced model creation time by about 80%. Time to build the first iteration of a new model has been reduced to about half a day, and about one hour for consecutive iterations

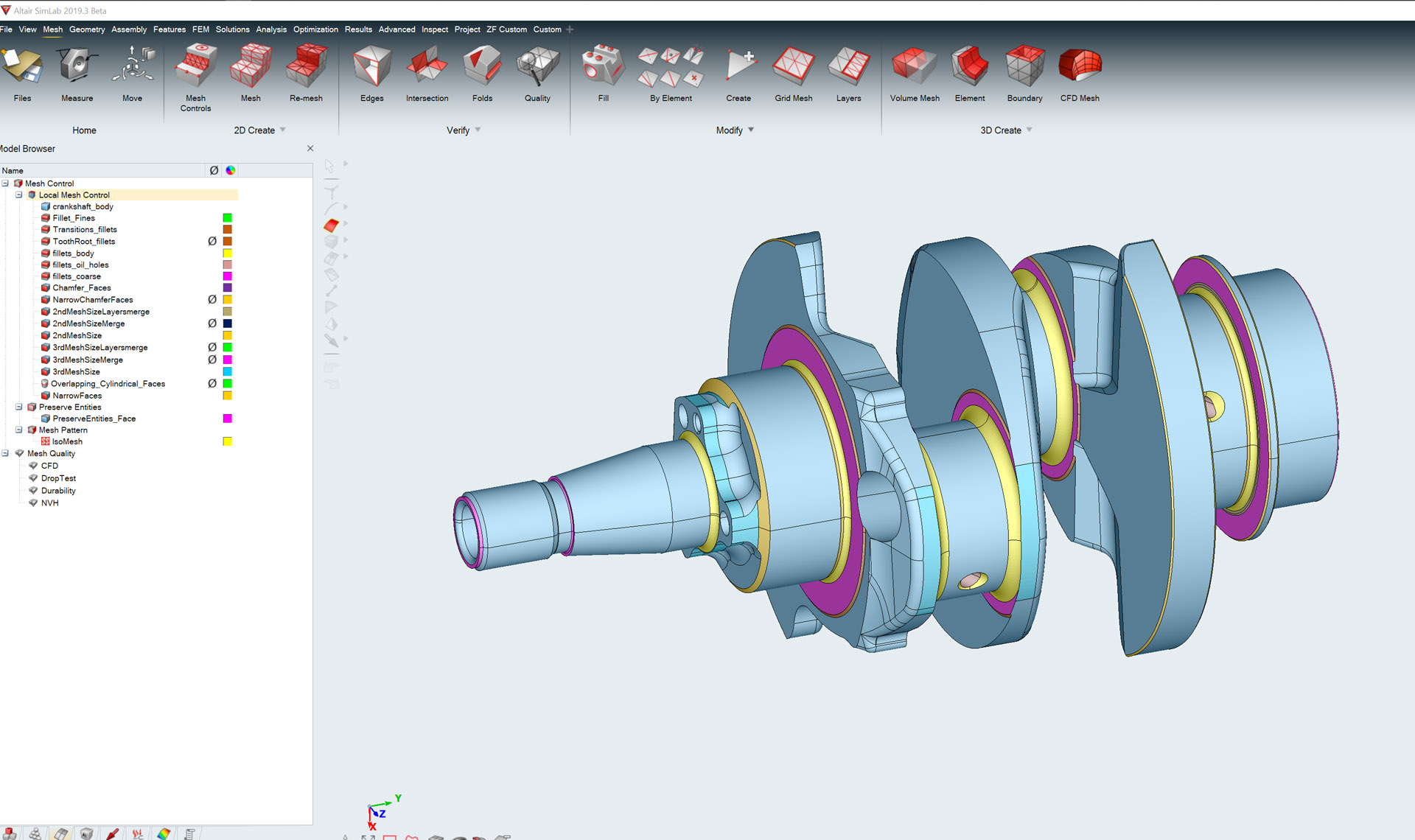

The resulting, semi-automated process used by BMW Motorrad to model an engine crankshaft for structural and fatigue analysis using SimLab now includes the following four steps: group assignment; mesh controls and surface mesh; layered elements, volume mesh and RBEs; and renumbering and group set definition.

Comparison tools inside SimLab identify the differences between the current model and new variant, and help to transfer the group structure from the current model to the new variant with very little user interaction to update the groups.

The group structure then provides the basis of the overall automated process.

Results roar into view

Using the SimLab process, BMW Motorrad has reduced model creation time by about 80%. Time to build the first iteration of a new model has been reduced to about half a day, and about one hour for consecutive iterations.

With this significant lead-time reduction, the primary benefit has been better budgetary forecasting and decision-making, along with record improvements in the production process and a greater degree of flexibility.

With model-building now brought in-house, models can be built as and when required, without having to rely on external providers.