Simulation, whether it’s Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD) or something else, is gaining momentum amongst the mainstream of designers and engineers — this we all know.

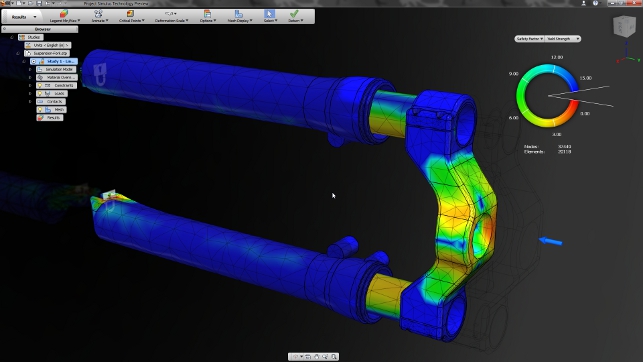

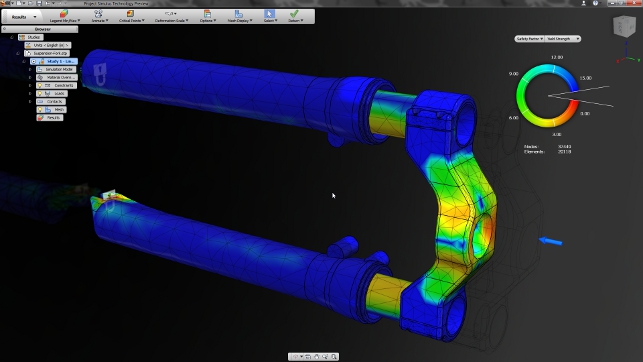

Project Simulus brings a Fusion, direct modelling basis tool for set-up and post processing of cloudbased simulation tasks

After all, the ability to take a digital model of a product that is “in design” through a process whereby you can gain a better understanding of how it performs under expected loading and operating conditions, is incredibly powerful.

Well, that is the theory. The reality is that simulation, while now more accessible than ever, has some aspects that are perhaps limiting its truly widespread adoption.

#1: Complexity

The first is complexity. Defining the physical, thermal or structural behaviour of a product is a complicated business.

While simulation technologies make much of assumption and simplification, the fact is that the real world is a complex one, so anything trying to simulate it is inherently complex as well.

As a result, simulation tools are complex beasts for anything other than trivial problems or demonstrations.

#2: Computation

The second is computation. Simulation of this order of complexity is computationally demanding.

Yes, FEA has come on leaps and bounds in recent years, driven by the increasingly common multi-core computers we have at our disposal, but it still takes time.

Once you factor in things like design of experiments, optimisation, convergence and iterative processes, it is time consuming process. While it may no longer be a matter of weeks for the majority, solve times can still stretch over hours, if not days.

Computation is costly, both in terms of hardware investment and time spent waiting for results.

#3: Cost

The third is cost — in terms of pure licensing costs and in other regards too.

In many cases, simulation tools have dropped in price, particularly when looking at the mainstream CAD integrated tools.

The wealth of tools available to many is quite incredible. At the higher-end of the spectrum, the likes of Ansys, Fluent, Abaqus, CFX, the costs are still extraordinarily high, usually on an annual license basis.

But alongside the software cost, there are other factors to consider. For instance, the hardware required to run these types of tasks locally should not be underestimated.

While workstation costs have dropped (or rather, you get more for the same money), a decent simulation speed system is still a heavy burden. Then, of course, there is also the cost of training and staffing.

Whether it’s a designer, an engineer or a specialist, they are going to need to know what they’re doing.

This is because they have to wrangle with the complexity discussed above, and they also need to ensure that the time and cost invested in simulation gives not only good value in terms of accuracy of results, but also in terms of usefulness to the development process.

So, bear these three things in mind as we look at what Autodesk is doing.

Autodesk 360

As most of our readers will be aware, amongst all of the vendors in the design and engineering software industry,

Autodesk is the one that’s pushing ahead with its cloud-based plans. The cloud is a highly attractive proposition for the software development community.

Maintenance of the software is centralised and piracy is reduced as a valid license and access is required. Although we’re nowhere near the stage where all of our tools can or even should be run from web-based servers, 3D design tools are one hell of a lot heavier than gmail or salesforce, but it’s coming. And faster, I suspect, than most of us realise.

But at the moment, widely available bandwidth means that the cloud holds the most potential in a couple of areas. Autodesk has set off on this path with Autodesk 360 PLM.

The off loading to servers of small, transaction based processes makes huge sense, of which PLM is a perfect example. The management of change, the accessibility of data to geographically dispersed teams, the ability to access it wherever, however you want — that’s a sweet spot for the cloud right there.

Small, lightweight activities on a database. Ironically, the other is computationally heavy processes — such as simulation.

Cloud-based computation is an interesting proposition — seemingly limitless racks of servers available to solve your every whim. The ability to take a study set-up, send it to a remote solver and have it calculated and sent back, without you having to invest in costly hardware, is highly attractive.

That said, there is a myth with regards to cloud-based computation that should be more widely dispelled. The cloud isn’t faster than a local machine. Not at all. These are still based on the same hardware we have in our local workstations.

Concurrent processing

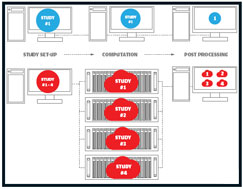

But what the cloud can do is compute multiple jobs concurrently in around the same time as a local machine.

Consider an optimisation or design of experiments study. Both of these require multiple variants of the same study to complete and find the best solution.

On a local machine, the number of these variants that can be solved at the same time is limited by the hardware in place. Even assuming that the software is capable of running parallel processes, this will always be the case.

With the cloud, there is a theoretically limitless number of workstations available. So, as a result, you can calculate a dramatically larger number of solves concurrently. This happens at the same time (give or take) but you get more data back.

More data back means a greater understanding of what influences the performance of the design, where things can be tweaked and improved. Yes, there will always be an additional time frame for prepping the study and uploading it to the server, but if you can take a DoE study down from days to hours, then there is an immediate gain.

Deliveries and price

So what does the Autodesk Simulation 360 offering contain and allow you to do?

The answer is pretty straight forward. There are three options available. We’ll deal with the entry level and mid-range first.

The entry level gives access to three key pieces of software, previously found in the company’s CFD and Mechanical analysis offerings (otherwise known as CFdesign and Algor).

Alongside this, access is also granted to a new piece of technology that combines Inventor Fusion with some simulation specific tools for pre and post processing.

This has been on the Autodesk Lab website for sometime under the codename Project Simulus. It’s still there and worth a look.

The concept is that you have these three tools for setting up simulation studies locally on a workstation. Then, when the time comes for solving, everything needed is transported to the cloud for computation.

Effectively, a job manager that sits in your task tray and monitors their progress. Once complete, you’re notified that the results are ready and these can be downloaded and inspected, reported on and decisions made.

The first two bundles are essentially the same technology but what differs is the amount of computation that can be done.

The entry level offering, priced at $3,950 per year, gives you 120 ‘jobs’. While the next bundle up, at $7,950, has an unlimited, all you can eat plan.

What constitutes a job?

One question that fascinates me is how Autodesk is quantifying “a job”. The cloud is a new field and many are still finding their feet in terms of units of measure and cost.

Autodesk is one of the first to announce a commercial service offering in the design space, so it’s interesting to learn more.

Essentially, as soon as you submit a study, that’s a “job” and your count goes down. Some studies and some other tasks, are interactive in nature, so will consume more.

Interestingly, one such example, optimisation, is exempt from this rule, so you can perform multi stage optimisations and it’ll just use one “job” credit.

Cloud vs local

As we’ve discussed, there are benefits to having cloud computation facilities available just as there are benefits to local computation.

With this in mind, it’s interesting that the high-end bundle of the offering you all of the tools discussed here, but also the ability to solve local as well. That’s about four grand more.

Conclusion

Simulation adoption isn’t as heavy as many might expect and certainly not as heavy as the vendors might have predicted.

Many are interested, but there are many things stopping them. We’ve discussed a number of them here in #1, #2 and #3.

So has Autodesk Simulation 360 solved them? In terms of cost, this is an attractive bundle of tools — particularly when you compare the cost of buying them on their own in a traditional manner.

In terms of computation, the cloud certainly can solve some issues, but not all. Local compute still has a lot of benefits. But in terms of complexity, this is one that still sticks.

Facts are, you can make the software as quick and as cheap as you like using whatever technologies are to hand, but simulation tools are still complex beasts.

Yes, the new Simulus tools based on Fusion are looking like a much better way to work, but they still don’t go far enough. But that’s a criticism across the entire industry, not just Autodesk.

Still, two out of three isn’t bad as a start. Autodesk has a lot of simulation technology these days and it’s interesting to see the changes in terms of how they are being packaged and used.

| Product | Simulation 360 |

|---|---|

| Company name | Autodesk |

| Price | £3,995 per year |