solidThinking Inspire 2016 – Inspire has forged the way for mainstream use of topology optimisation that is now rapidly becoming a hot topic in the design software industry. We take a look at the latest release which advances the art

Originally released under the name Morphogenesis, solidThinking Inspire is a system devoted to topology optimisation and, until recently, was one of the only products on the market aimed at the mainstream, rather than the FEA specialist.

solidThinking Inspire 2016 brings on line a set of tools to help you not only optimise your design using FEA methods, but also to use SubD style creation of geometry that’s more usable

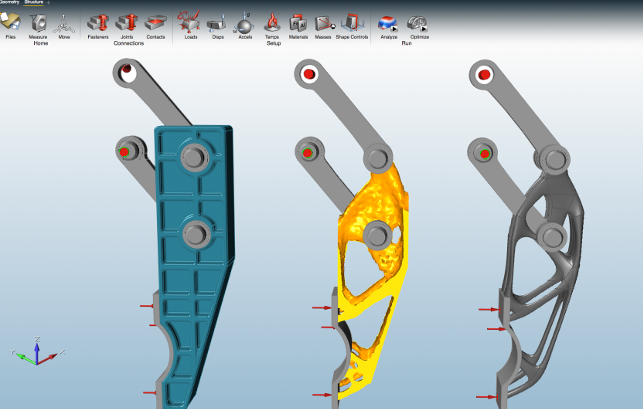

The idea is that you begin with a set of geometry, either created from scratch or imported from your CAD system. Define the loading conditions and the material and then let the system optimise that form according to your design goals such as weight reduction, stiffness maximisation and so on.

solidThinking Inspire 2016 – General updates

The solidThinking Inspire interface hasn’t changed a great deal for this release.

It still features a large model and set-up window, with a row of icons across the top of the screen and a model browser on the left, though this isn’t used all that much.

However, what has changed is that the functions (for reasons that will become clear shortly) have now been separated into different sections for file interactions (import/export), view, geometry, structure and analysis.

If you’re new to Inspire, it’s worth spending some time exploring each icon.

Unlike most systems where the icon invokes a single operation, within solidThinking Inspire each icon has different operations. For example, it’s a single icon for boundary conditions definition. Depending on the part of the icon (you’ll quickly pick this up), you can assign constraints, loads, pressures, torque etc.

On that subject, the solidThinking Inspire 2016 release also sees an expanded set of constraints. This means you can now add in details of enforced displacements, angular velocity and acceleration, g-loads and temperature.

In terms of simulations that can be incorporated into the optimisation process, the same set of structural tools is available, but this release adds the ability to incorporate buckling analysis into the mix as well.

//giphy.com/embed/umzI2hqbk1E2c

solidThinking Inspire 2016 – PolyNURBS

While the updates and introductions covered so far are extensions of tools from the previous releases, the big news for this release is the introduction of PolyNURBS.

This technology comes directly from solidThinking Evolve, the company’s conceptual design focussed system.

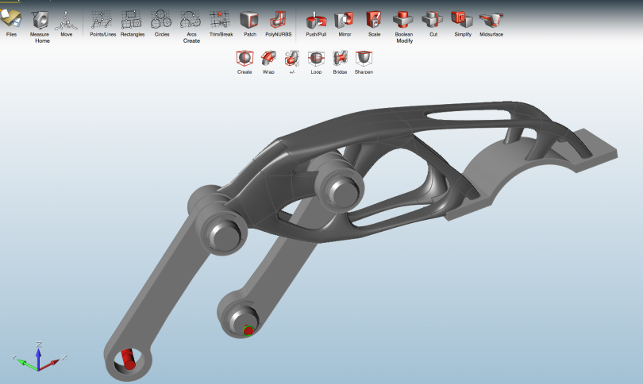

The overall idea is that you use control cages to generate smooth organic shapes (much like sub division or SubD modelling techniques now in many systems), but as soon as you stop editing that cage, the system generates NURBS surfaces rather than requiring some form of conversion.

In the Inspire environment, these tools have been built into a new set of operations called “Shape” and the reason you use them is fascinating — so let’s explore.

The biggest issue with many topology optimisation tools is that the end result is a CAE-derived mesh — which, if you’ve used such tools, isn’t exactly aesthetically pleasing or easy to manufacture.

The result is that topology optimisation is often pitched as a means of gaining inspiration for your next design variation based on analysis and optimisation (hence the name of this product, I suspect). You then need to do a full redesign using your traditional tools.

solidThinking Inspire 2016 changes this by including SubD-like modelling tools that have been adapted to enable better looking products to be built by allowing you to quickly snap sections, refine them and generate smooth features from FEA-like mesh. The workflow is something like this.

Once you’ve completed the optimisation routines and arrived at a rough form, you then switch to the Shape environment.

Here you start to layout the prismatic shape as well as use the PolyNURBS tools to dynamically find sections and construct a much more consistent model around that mesh.

The system helps by providing a quick selection of possible sections and fitting the profiles in position. As you do this, the form is built up roughly, but it’s much smoother than you’d expect.

At any point, you can dive in and adapt the cage to push, pull, rotate and generally tweak the shape to get it to where you want it.

What’s interesting is that this sits nicely alongside the geometry modelling tools, which have been inside solidThinking Inspire for the last couple of releases, and allows you to mix both the freeform geometries built using PolyNURBS and more prismatic features.

The benefit there is that you can then take those forms and run them back through the analysis process to validate your design.

Taking its PolyNURBS technology from solidThinking Evolve, Inspire now allows you to create much more manufacturable forms that are functionally rich and easier to process

In conclusion

The last year or so has seen a growing interest in topology optimisation.

Much of this has been driven by the after effects of the 3D printing hype bubble and although that is dying away now, many organisations have realised that these manufacturing techniques allow more freedom in terms of geometry than more traditional manufacturing methods. And to make the most of those benefits, we need a different set of tools to design the subsequent parts.

The issue with topology optimisation has always been that, while it could point you toward the optimum end result in terms of rough shape, these results weren’t particularly useful, even with today’s additive manufacturing processes.

Most companies want parts that have a more aesthetically pleasing form inside too.

As someone involved in the space industry recently told me, “we know we can save weight using the technology, but we don’t want our parts to look shit.” There’s also the fact that having smoother surfaces on components can give additional benefits other than pure aesthetics — think; finishing, polishing, post treatment etc.

This is where solidThinking has pulled it out of the bag with this latest release as it’s introduced PolyNURBS, which allows smooth organic shapes to be created by the generation of NURBS surfaces.

What’s also interesting for this release is that Inspire brings together a set of tools that lets you explore a product’s performance conditions too. So, alongside all of the new tools and physics models, you now have access to a new set of comparison tools to enable you to compare results sets as you create them.

After all, while optimisation can provide the optimal result for a set of conditions, that doesn’t necessarily mean that you have just a single result to work off and trade-offs need to be made, even in this quite linear workflow.

As you can see from the NX 11 review, topology optimisation is becoming a part of workhorse design tools. That said, it’s still early days for this example and Inspire offers a much richer set of technology and, perhaps more importantly, controls over the process.

| Product | Inspire 2016 |

|---|---|

| Company name | solidThinking |

| Price | TBC |